A kind of perovskite light-emitting diode based on spraying process and its preparation method

A light-emitting diode and perovskite technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of limiting the industrialization development of perovskite light-emitting diodes, and the inability to apply large-area devices, and achieve the Small, low roughness, enhanced controllability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

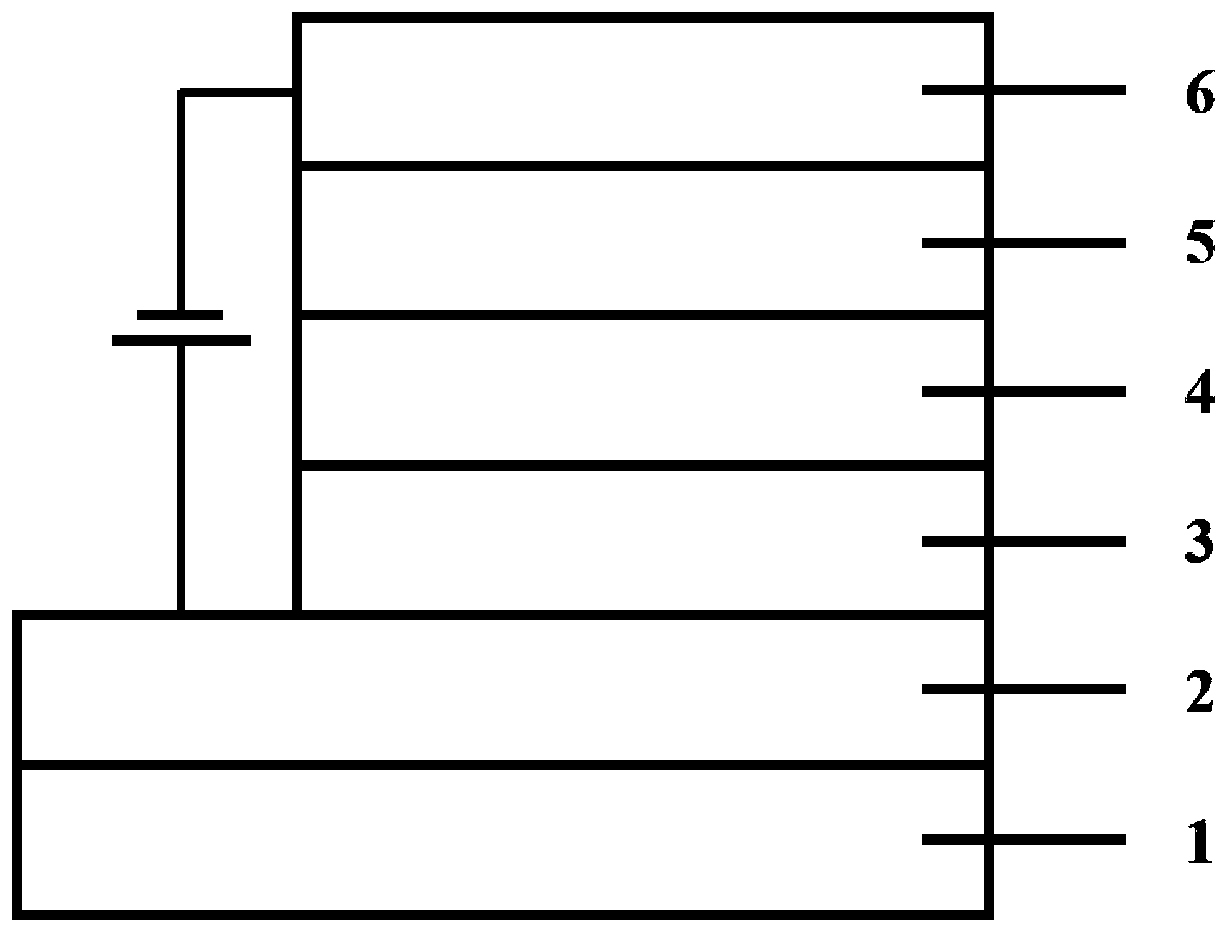

[0027] A method for preparing a perovskite light-emitting diode based on a spraying process, the method comprising the steps of:

[0028] 1. Use ITO glass as the substrate of the substrate, use acetone, deionized water and ethanol solution to ultrasonically clean the substrate, and dry it with dry nitrogen after cleaning.

[0029] 2. Carry out UV pretreatment to the substrate of the substrate produced in step 1.

[0030] 3. Transfer to the glove box, and prepare an anode layer on the substrate treated in step 2. The anode layer is any one or more combinations of ITO, graphene or carbon nanotubes, preferably ITO is the anode.

[0031] 4. In the glove box, use the spraying method to spray a solution of a material with hole transport properties on the anode layer treated in step 3, and then heat the substrate at a temperature of 100-150 °C for 5-15 minutes to prepare a hole transport layer, which has Hole-transport materials can be selected from PEDOT:PSS and traditional polymer...

Embodiment 1

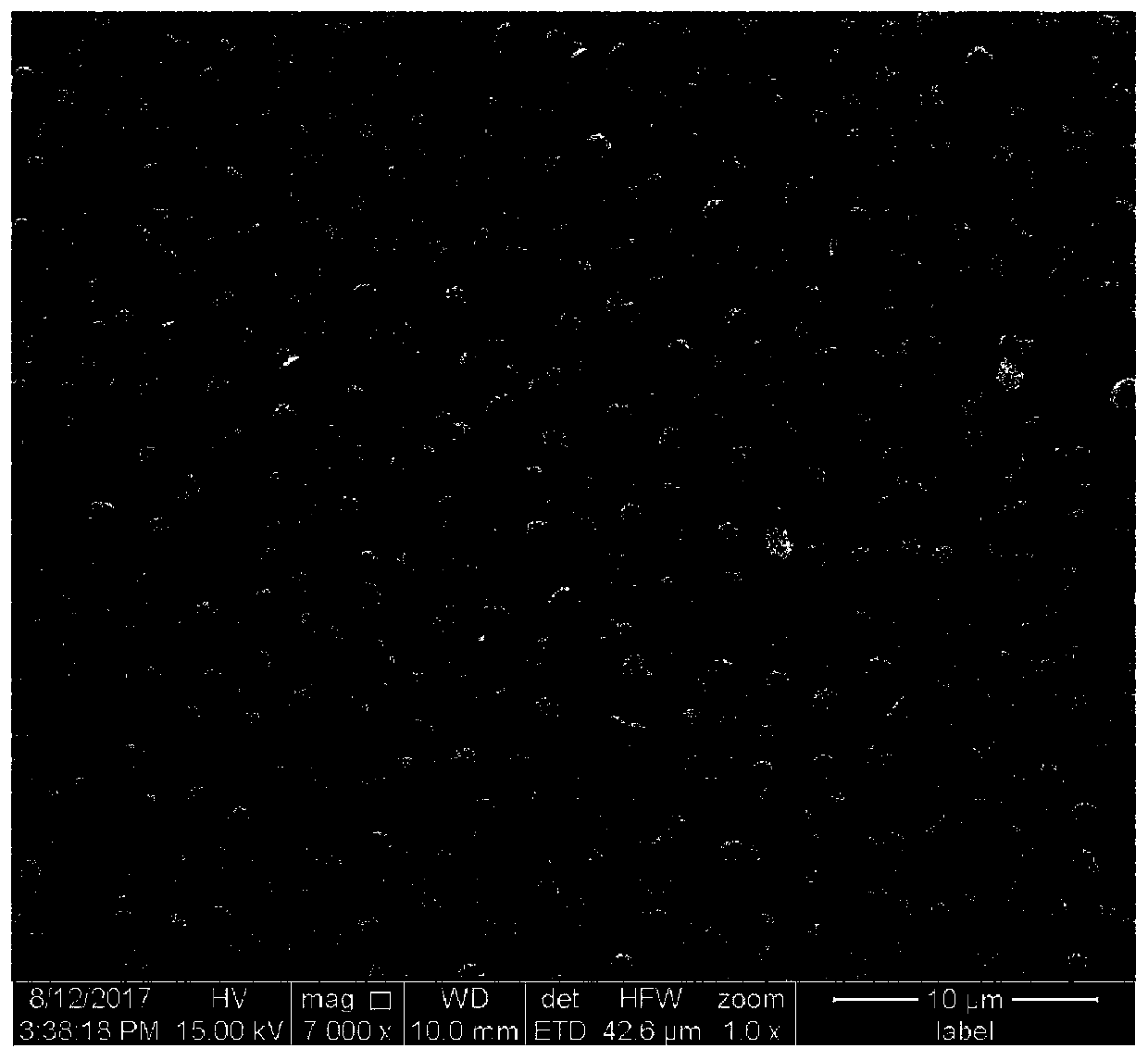

[0046] Spray PEDOT:PSS solution on a transparent conductive substrate, and heat it at 150°C for 10min to prepare a hole transport layer; place the substrate on a low-temperature backplate and cool it down to 5°C, and spray 40wt% dimethyl of PbBr2 and CH3NH3Br Keep the formamide (DMF) solution for 10 minutes; heat the substrate on a hot stage to 80°C for 40 minutes, then spray 2mol / L PCBM chlorobenzene solution; finally spray the alcohol solution of silver nanowires and heat at 100°C 5min, the perovskite light-emitting diode was prepared.

[0047] Its lighting voltage is 3V, and its maximum brightness is 12432cd / m2.

Embodiment 2

[0049] Spray PEDOT:PSS solution on a transparent conductive substrate, and heat at 150°C for 10 minutes to prepare a hole transport layer; place the substrate on a low-temperature backplate and cool it down to -10°C, and spray 20wt% dimethylformamide of PbBr2 and CH3NH3Br Dimethyl formamide (DMF) solution was maintained for 20 minutes; the substrate was placed on a hot stage and heated to 100°C for annealing for 40 minutes, and then sprayed with 2mol / L PCBM chlorobenzene solution; finally, the tungsten wire was heated in a vacuum chamber to evaporate 0.5nm LiF and 100nm Al electrodes were used to fabricate perovskite light-emitting diodes.

[0050] Its lighting voltage is 2.7V, and its maximum brightness is 7632cd / m2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com