Preparation method of flexible thin film lithium ion pole plate

A flexible film, lithium ion technology, applied in the field of lithium ion batteries, can solve the problems of low load uniformity of active materials, limited active material loading, difficult and uniform dispersion of nanofibers and carbon nanotubes, etc., to reduce contact resistance. , easy separation and recycling, improve the effect of electrochemical activity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

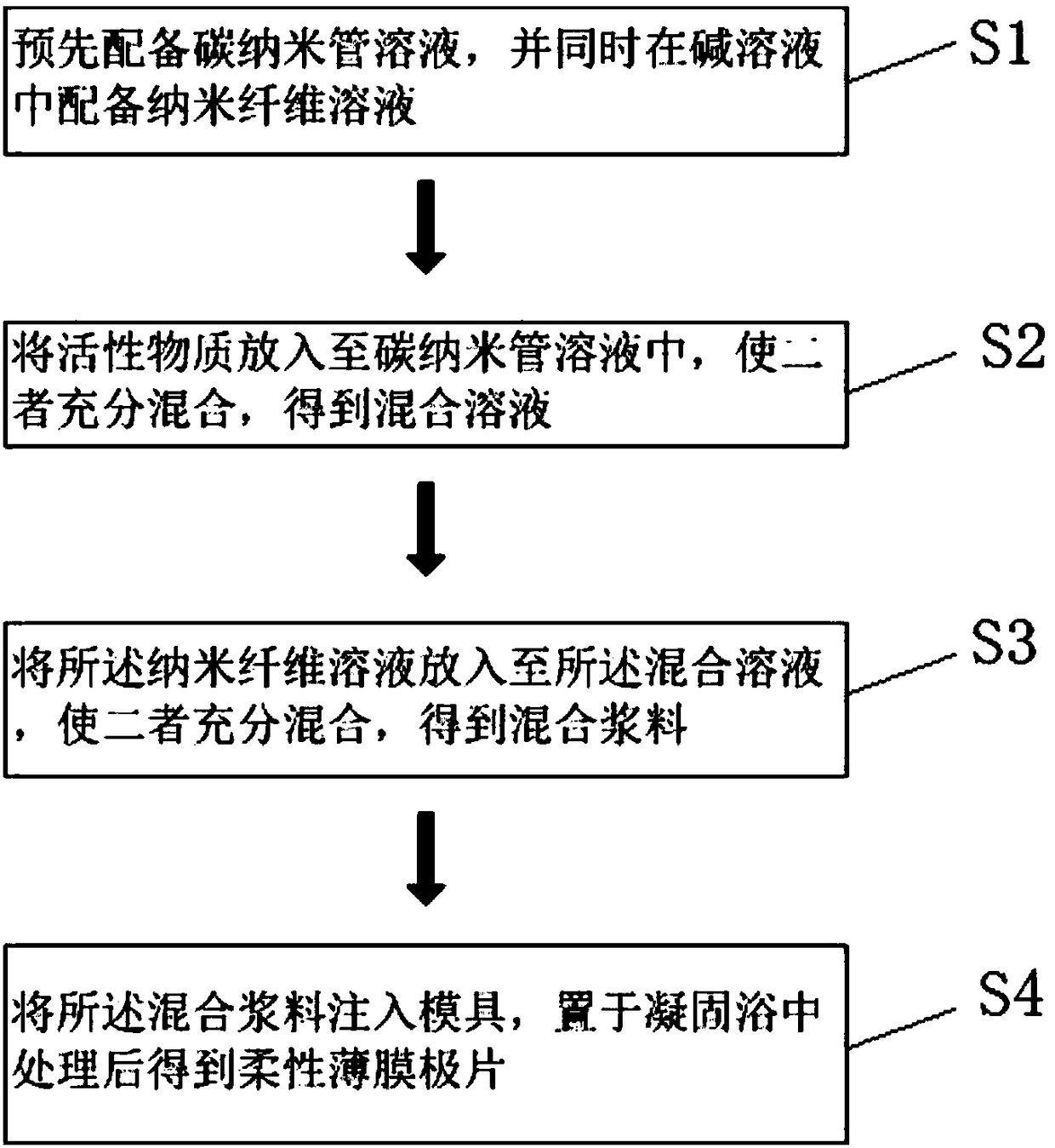

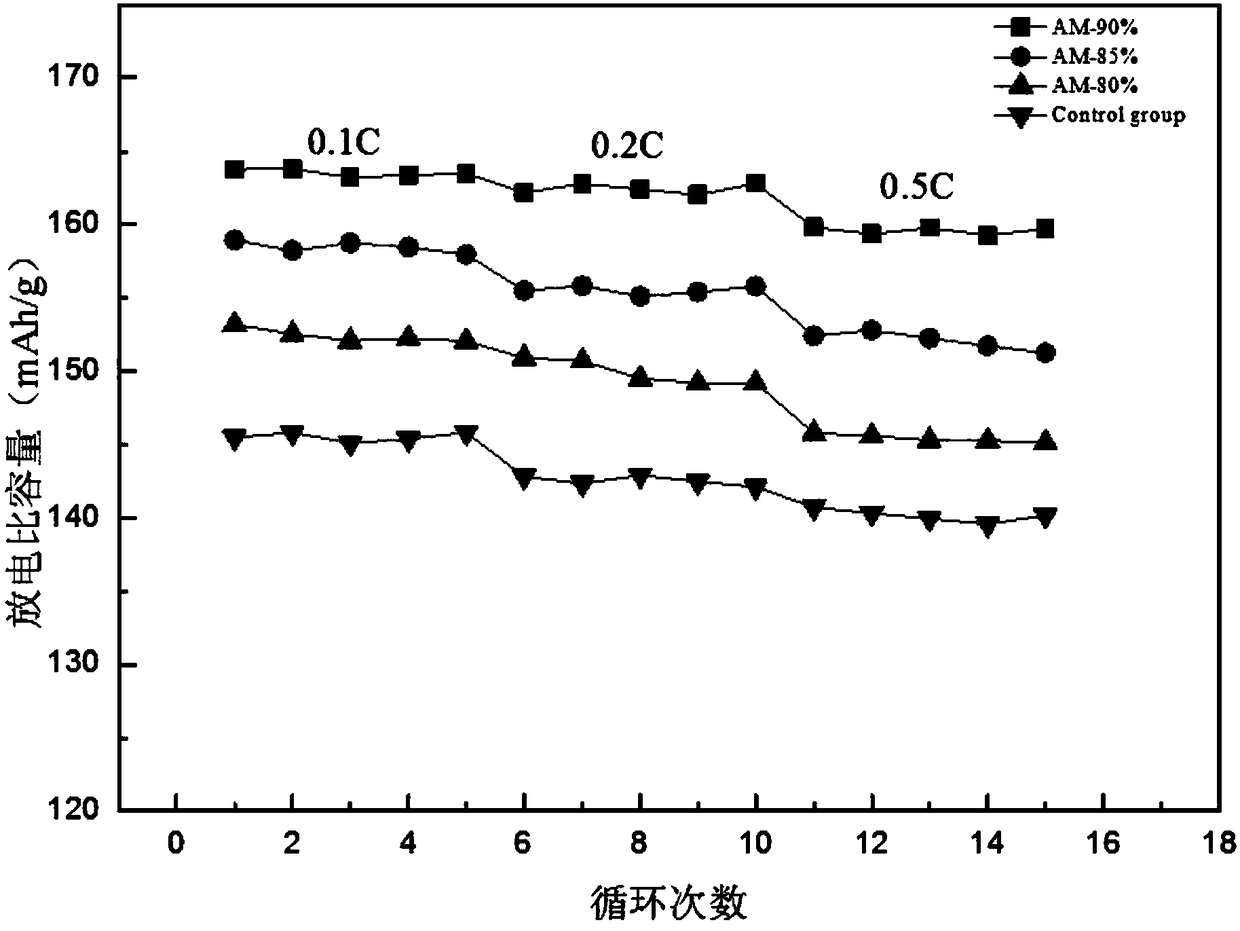

[0025] see figure 1 , the embodiment of the present invention provides a method for preparing a flexible thin-film lithium ion pole piece, comprising the following steps: S1, prepare a carbon nanotube solution in advance, and simultaneously prepare a nanofiber solution in an alkali solution; S2, put the active material into the In the carbon nanotube solution, the two are fully mixed to obtain a mixed solution; S3, the nanofiber solution is put into the mixed solution, and the two are fully mixed to obtain a mixed slurry; S4, the mixed slurry The material is poured into the mold and placed in a coagulation bath to obtain a flexible thin film pole piece. In this embodiment, the nanofibers are first dissolved into a molecular chain state by an alkaline solution, and then the active material and carbon nanotubes are mixed, and the nanofibers are regenerated after passing through a coagulation bath. Not only can a pole piece with a high load of active material be prepared, but als...

Embodiment 1

[0033] Embodiment 1, concrete operation steps are as follows:

[0034] a. Weigh 0.5g of nanofibers (NF) in 100mL of NaOH / Urea aqueous solution, and stir at -12°C to obtain a nanofiber solution;

[0035] b. Weigh 0.5g of carbon nanotubes (CNTs, with a diameter of 20-40nm) in 100mL of deionized water, and obtain a carbon nanotube dispersion after ultrasonic dispersion;

[0036] c, weigh 9g lithium cobaltate (LiCoO 2 ) was added to the carbon nanotube aqueous solution and stirred for 30min to make LiCoO 2 Mix well with CNTs to get LiCoO 2 and CNTs mixture;

[0037] d, The nanofiber solution was added dropwise to LiCoO 2And in the CNTs mixture, continue stirring for 1h to obtain lithium cobaltate / carbon nanotube / nanofiber (LCO / CNTs / NF) mixed slurry;

[0038] e, inject the LCO / CNTs / NF mixed slurry into the mold (area 12cm*12cm, PTFE square concave plate with a depth of 200μm), place it in the coagulation bath for 120s to regenerate the nanofibers, and obtain flexible cobalt af...

Embodiment 2

[0040] Embodiment 2, concrete operation steps are as follows:

[0041] a. Weigh 0.75g of nanofibers (NF) in 100mL of NaOH / Urea aqueous solution, and stir at -12°C to obtain a nanofiber solution;

[0042] b. Weigh 0.75g of carbon nanotubes (CNTs, with a diameter of 20-40nm) in 100mL of deionized water, and obtain a carbon nanotube dispersion after ultrasonic dispersion;

[0043] c, weigh 8.5g lithium cobaltate (LiCoO 2 ) was added to the carbon nanotube aqueous solution and stirred for 30min to make LiCoO 2 Mix well with CNTs to get LiCoO 2 and CNTs mixture;

[0044] d, The nanofiber solution was added dropwise to LiCoO 2 And in the CNTs mixture, continue stirring for 1h to obtain lithium cobaltate / carbon nanotube / nanofiber (LCO / CNTs / NF) mixed slurry;

[0045] e, inject the LCO / CNTs / NF mixed slurry into the mold (area 12cm*12cm, PTFE square concave plate with a depth of 200μm), place it in the coagulation bath for 120s to regenerate the nanofibers, and obtain flexible coba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com