Strip-shaped manganese-based catalyst for catalytic oxidation of NO and preparation method of strip-shaped manganese-based catalyst

A strip-shaped manganese-based, catalytic oxidation technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of insufficient crushing strength of catalysts, poor resistance to sulfur and water, and difficulties in industrial application and other problems, to achieve good industrial application prospects, good plasticity, and promote the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

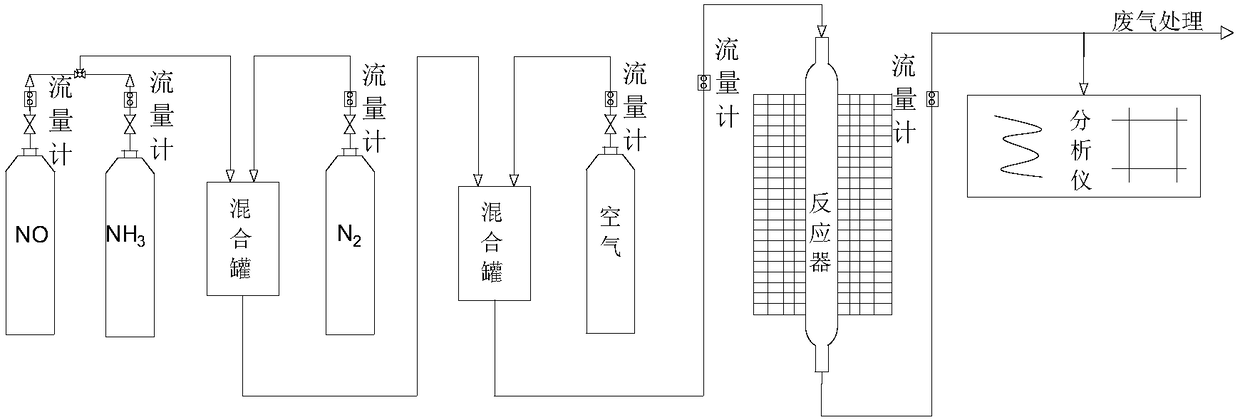

Method used

Image

Examples

Embodiment 1

[0030] The bar-shaped manganese-based catalyst of the present embodiment 1 uses manganese nitrate as the precursor of the catalyst, and uses ZSM-5 molecular sieve as the carrier of the catalyst. The mass fraction of manganese in the catalyst precursor is 10%, and the obtained bar-shaped manganese The base catalyst has a cross-sectional diameter of 3 mm.

[0031] The preparation method of the bar-shaped manganese-based catalyst of present embodiment 1 is as follows:

[0032] Step 1, the preparation of catalyst precursor: get 50ml 25 ℃ of distilled waters in the three necked round bottom flask of 250ml, the Mn(NO of 3.26g 3 ) 2 Dissolve in the above aqueous solution, and add 10g of H-β molecular sieve into the above solution, mechanically stir for 3 hours in a water bath at 25°C, evaporate excess water by heating in a water bath at 75°C, and vacuum dry at 100°C for 12 hours, then Calcined in a muffle furnace at 400°C for 5h, with a heating rate of 5°C / min, the obtained Mn-ZSM-...

Embodiment 2

[0036] The bar-shaped manganese-based catalyst of the present embodiment 2 uses manganese acetate as the precursor of the catalyst, uses ZSM-5 molecular sieve as the carrier of the catalyst, and the mass fraction of manganese in the catalyst precursor is 10%, and the obtained bar-shaped manganese The base catalyst has a cross-sectional diameter of 3 mm.

[0037] The preparation method of the bar-shaped manganese-based catalyst of present embodiment 2 is as follows:

[0038] Step 1, preparation of catalyst precursor:

[0039] Take 50ml of distilled water at 25°C in a 250ml three-neck round bottom flask, and put 4.46g of C 4 h 6 MnO 4 4H 2O was dissolved in the above aqueous solution, and 10g of ZSM-5 molecular sieve was added to the above solution, mechanically stirred in a water bath at 25°C for 3h, then heated in a water bath at 75°C to evaporate excess water, and vacuum dried at 100°C for 12h, then Calcined in a muffle furnace at 400°C for 5h, with a heating rate of 5°C...

Embodiment 3

[0044] The bar-shaped manganese-based catalyst of the present embodiment 3 uses manganese nitrate as the precursor of the catalyst, and uses H-β molecular sieve as the carrier of the catalyst. The mass fraction of manganese in the catalyst precursor is 20%, and the obtained bar-shaped manganese The base catalyst has a cross-sectional diameter of 4 mm.

[0045] The preparation method of the present embodiment 3 bar-shaped manganese-based catalysts is as follows:

[0046] Step 1, preparation of catalyst precursor:

[0047] Get 50ml of distilled water at 25°C in a 250ml three-necked round-bottomed flask, add 6.51g of Mn(NO 3 ) 2 Dissolve in the above aqueous solution, add 10g of H-β molecular sieve to the above solution, mechanically stir for 5 hours in a water bath at 25°C, evaporate excess water by heating in a water bath at 75°C, and vacuum dry at 100°C for 12 hours; then Calcined in a muffle furnace at 400°C for 5h, with a heating rate of 5°C / min, the obtained Mn-β catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com