A kind of ethylbenzene production device and process

An ethylbenzene and process technology, applied in the field of ethylbenzene production devices, can solve problems such as affecting the purity of reaction products, and achieve the effects of high added value, significant economic benefits, and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

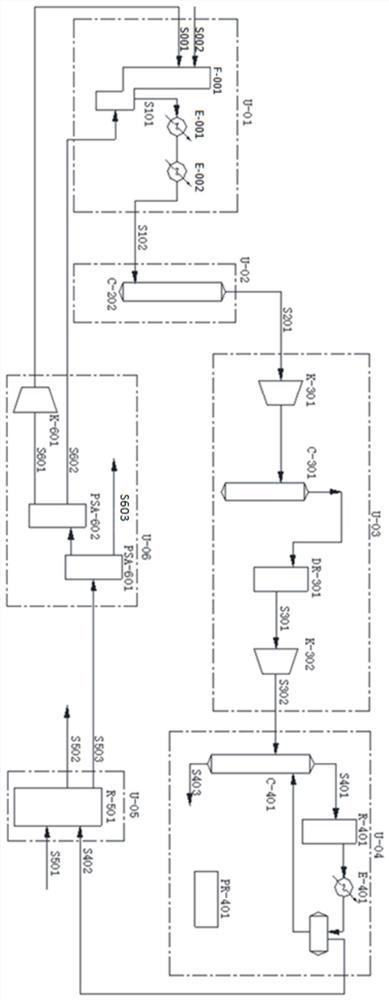

[0020] According to a preferred embodiment of the present invention, the tail gas recovery unit includes a primary pressure swing adsorption system, a secondary pressure swing adsorption system and an ethane booster connected in sequence.

[0021] According to the present invention, the function of the compression unit is to remove the acid gas and moisture in the cracked gas, and send the treated cracked gas to the cold separation unit after boosting its pressure. Preferably, the compression unit includes a primary booster compressor, an alkali washing tower, a dryer and a secondary booster compressor connected in sequence.

[0022] Wherein, the alkali washing tower is used to remove acid gas (CO 2 、H 2 S), the dryer is used for dehydration.

[0023] Preferably, the primary step-up compressor and the secondary step-up compressor are units that share a set of casings and rotors.

[0024] According to the present invention, the cold separation unit includes a deethanizer, a ...

specific Embodiment approach

[0033] According to a specific implementation manner, the ethylbenzene production process includes the following processes:

[0034] 1) Cracking the circulating cracking raw material and the fresh cracking raw material in the cracking furnace of the cracking unit into cracking gas at the outlet of the cracking furnace, and cooling by a heat exchanger to obtain the cooled cracking gas;

[0035] 2) After the cooling, the cracked gas is sent into the quenching unit for further cooling to obtain the cracked gas at the inlet of the compressor;

[0036] 3) the cracked gas at the inlet of the compressor is boosted by a step-up compressor in the compression unit, and the acid gas is removed in the alkali washing tower to obtain the cracked gas after the step-up deacidification, and then dried by a drier, Send it to the secondary boost compressor to boost the pressure again to obtain the cracked gas after the secondary boost;

[0037] 4) After the second pressurization, the cracked ga...

Embodiment 1

[0053] This embodiment is used to illustrate the ethylbenzene production device and process of the present invention.

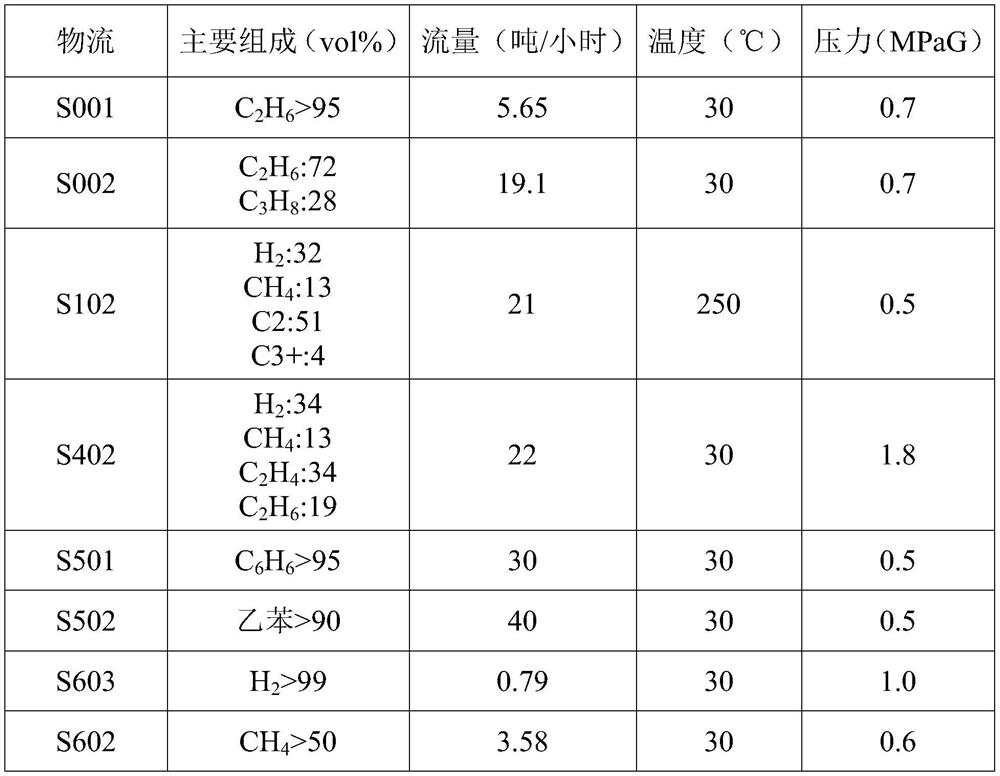

[0054] Such as figure 1 As shown, in this embodiment, the primary booster compressor K-301 and the secondary booster compressor K-302 of the compression unit U-03 share a set of casings and rotors.

[0055] The cooling capacity of the condenser E-401 in the cold separation unit U-04 is provided by the propylene refrigeration system PR-401.

[0056] Tail gas recovery unit U-06 includes a primary pressure swing adsorption system PSA-601, a secondary pressure swing adsorption system PSA-602 and an ethane booster K-601 connected in sequence.

[0057] Specifically, ethylbenzene production process comprises the following steps:

[0058] 1) Crack the circulating cracking raw material S001 and the fresh cracking raw material S002 in the cracking furnace F-001 to obtain the cracked gas S101 at the outlet of the cracking furnace, which is cooled by the first heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com