A kind of transparent colorless polyimide film for amoled, preparation method and amoled device

A polyimide film and polyimide technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of reducing the thermal expansion coefficient of the film, poor comprehensive performance of the film, and complicated preparation methods, etc. Achieve the effect of optimizing the reaction mechanism, high heat resistance and low thermal expansion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

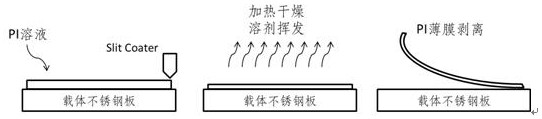

Method used

Image

Examples

Embodiment 1

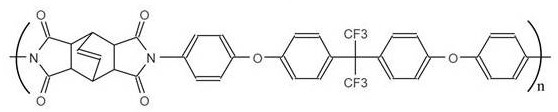

[0026] (1) Pass high-purity nitrogen gas into the 5L reactor, and the nitrogen flow rate must be controlled at not less than the heat flux of the volume above the liquid level of the reactor. At the same time, 2556 g of N,N-dimethylacetamide (DMAC) was added, and then the temperature of the reaction kettle was adjusted to 25°C. Gradually add 311.07g of 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane, start the stirrer, the rotor speed is 100~300rpm, add 50.4g of glacial acetic acid to the above reaction kettle As a catalyst, high-purity nitrogen is continuously fed into the reactor.

[0027] (2) Keep stirring for 30-60 minutes after the reaction kettle is sealed until the powdery solid dissolves.

[0028] (3) Gradually add 148.91g of bicyclo[2.2.2]oct-7-ene-2,3,5,6-tetracarboxylic dianhydride to the above mixed solution, and first stir at -10°C for 2 hours, Then it was warmed up to 25° C. and stirred continuously for 12 hours.

[0029] (4) After the stirring is completed...

Embodiment 2

[0036] (1) Pass high-purity nitrogen gas into the 5L reactor, and the nitrogen flow rate must be controlled at not less than the heat flux of the volume above the liquid level of the reactor. At the same time, 2299 g of N,N-dimethylacetamide (DMAC) was added, and then the temperature of the reaction kettle was adjusted to 25°C. Gradually add 192.14g of 2,2'-bis(trifluoromethyl)diaminobiphenyl, start the stirrer, the rotor speed is 100~300rpm, add 50.4g of glacial acetic acid as a catalyst to the above reaction kettle, Continuously feed high-purity nitrogen.

[0037](2) Keep stirring for 10 minutes after the reaction kettle is sealed until the powdery solid dissolves.

[0038] (3) Add 222.51 g of 4,4'-(hexafluoroisopropylidene) phthalic anhydride to the above mixed solution, stir at -10°C for 2 hours, then return to 25°C and Stirring was continued for 12 hours.

[0039] (4) After the stirring is completed, a polyimide prepolymer (PAA) slurry with a solid concentration of 15 ...

Embodiment 3

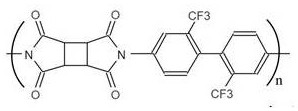

[0045] Except that the 4,4'-(hexafluoroisopropylidene) phthalic anhydride of 222.51g of Example 2 is replaced by 1,2,3,4-cyclobutanetetracarboxylic dianhydride of 117.66 g, to implement Example 3 was carried out in the same manner as Example 2, and the imidization of the obtained polyimide film was not less than 99%. Its polyimide structure is shown in formula III:

[0046]

[0047] Formula III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com