Tungsten disulfide/graphene oxide composite material and preparation method and application thereof

A technology of tungsten disulfide and composite materials, which is applied in the field of material science, can solve the problems that the performance of electrode materials cannot be greatly improved, and the advantages of specific surface area are lost, so as to improve electrochemical performance, increase dispersion and specific surface area, Avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In some embodiments, the preparation method comprises:

[0040] Mix tungsten disulfide and sodium nitrate evenly, continue to stir under ice bath conditions, and slowly add concentrated sulfuric acid, continue to stir for more than 20 minutes, then slowly add potassium permanganate, and continue to stir for more than 15 minutes to form the first reaction mixture;

[0041] Continue stirring the first reaction mixture at room temperature for more than 12 hours, then slowly add deionized water dropwise, continue stirring for more than 30 minutes, then slowly add hydrogen peroxide, and continue stirring for more than 2 hours to form a second reaction mixture;

[0042] Separating and obtaining a uniform dispersion of tungsten disulfide nanosheets from the second reaction mixture;

[0043] Mix the homogeneous dispersion of tungsten disulfide nanosheets with the homogeneous dispersion of graphene oxide prepared by Hummer's method, and ultrasonicate for more than 2 hours to obt...

Embodiment 1

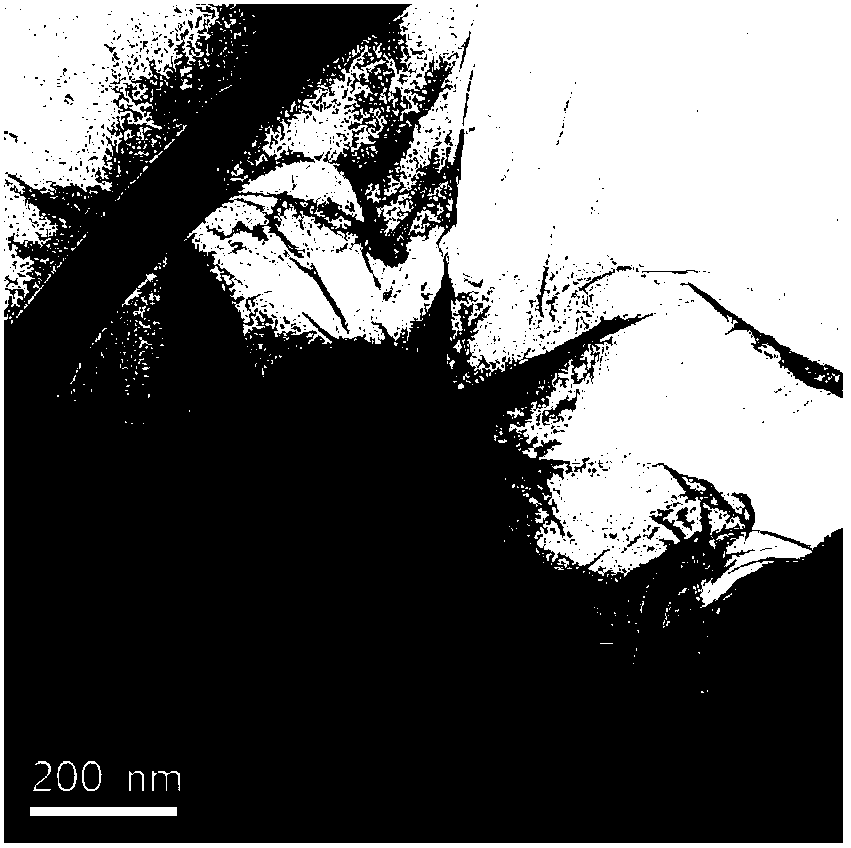

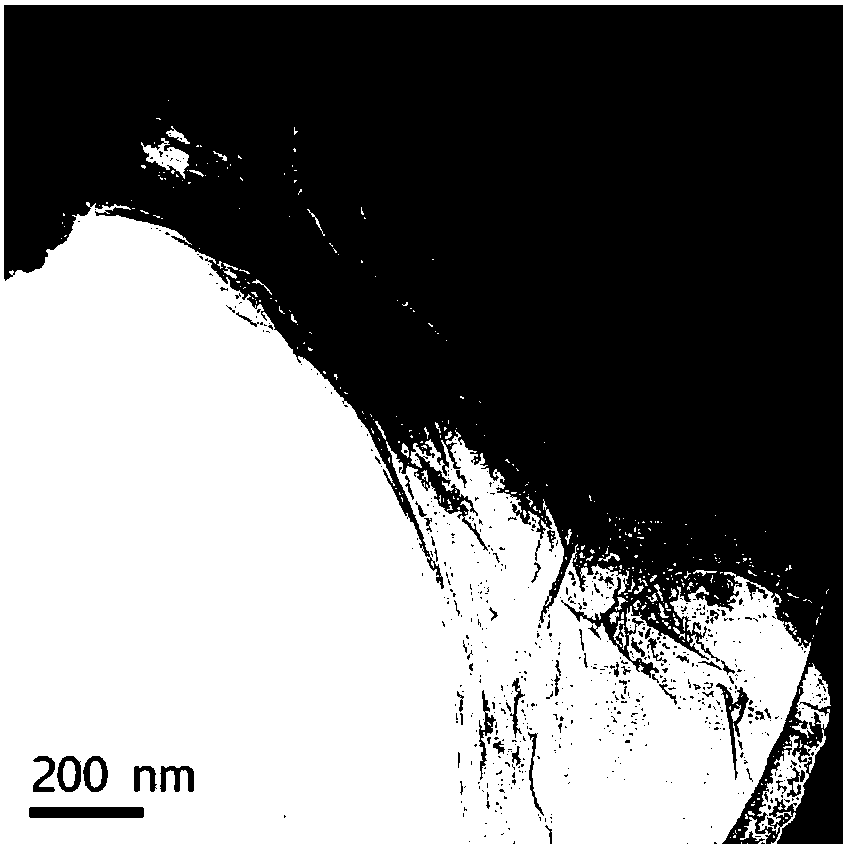

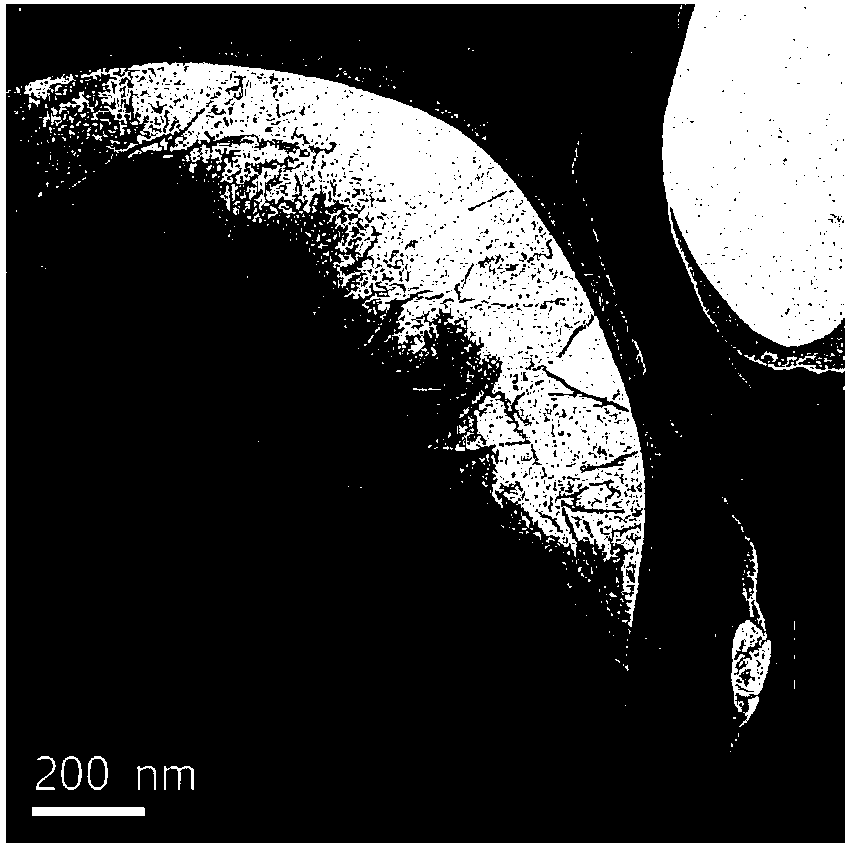

[0061] Embodiment 1: This embodiment provides a tungsten disulfide / graphene oxide composite material, wherein tungsten disulfide nanosheets are interspersed between atomic layers of graphene oxide.

[0062] The preparation method of this tungsten disulfide / graphene oxide composite material comprises:

[0063] 1. Preparation of tungsten disulfide nanosheets

[0064] (1) Mix 1.5g of tungsten disulfide and 0.17g of sodium nitrate powder evenly, keep stirring in an ice bath, and slowly add 11.5mL of concentrated sulfuric acid into the mixture of tungsten disulfide and sodium nitrate;

[0065] (2) Maintain the ice bath and stirring conditions described in step (1), after 20 minutes, slowly add 1.5g potassium permanganate, and continue to stir for 15min;

[0066] (3) Remove the ice bath, continue stirring at room temperature (about 25°C) for 12 hours, slowly add 50 mL of deionized water (about 60°C), and continue stirring for 30 minutes, then slowly add 1.6 mL of 30% hydrogen perox...

Embodiment 2

[0074] Embodiment 2: This embodiment provides a tungsten disulfide / graphene oxide composite material, wherein tungsten disulfide nanosheets are interspersed between graphene atomic layers.

[0075] The preparation method of this tungsten disulfide / graphene oxide composite material comprises:

[0076] Step (1) to step (4): exactly the same as step (1) to step (4) in Example 1 to obtain a tungsten disulfide / graphene oxide composite material;

[0077] Step (5): Add ammonia water dropwise to the dispersion of the aforementioned tungsten disulfide / graphene oxide composite material and keep stirring to increase the pH value from 7 to 10, and then continue to sonicate for about 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com