Preparing method of phosphorus-doped silicone epitaxial slice for 200 mm Schottky pipe

A technology of epitaxial wafers and phosphorus silicon, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of device yield impact, low growth rate, and increased turn-on voltage, so as to achieve good expansion resistance matching and improve growth Speed, the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

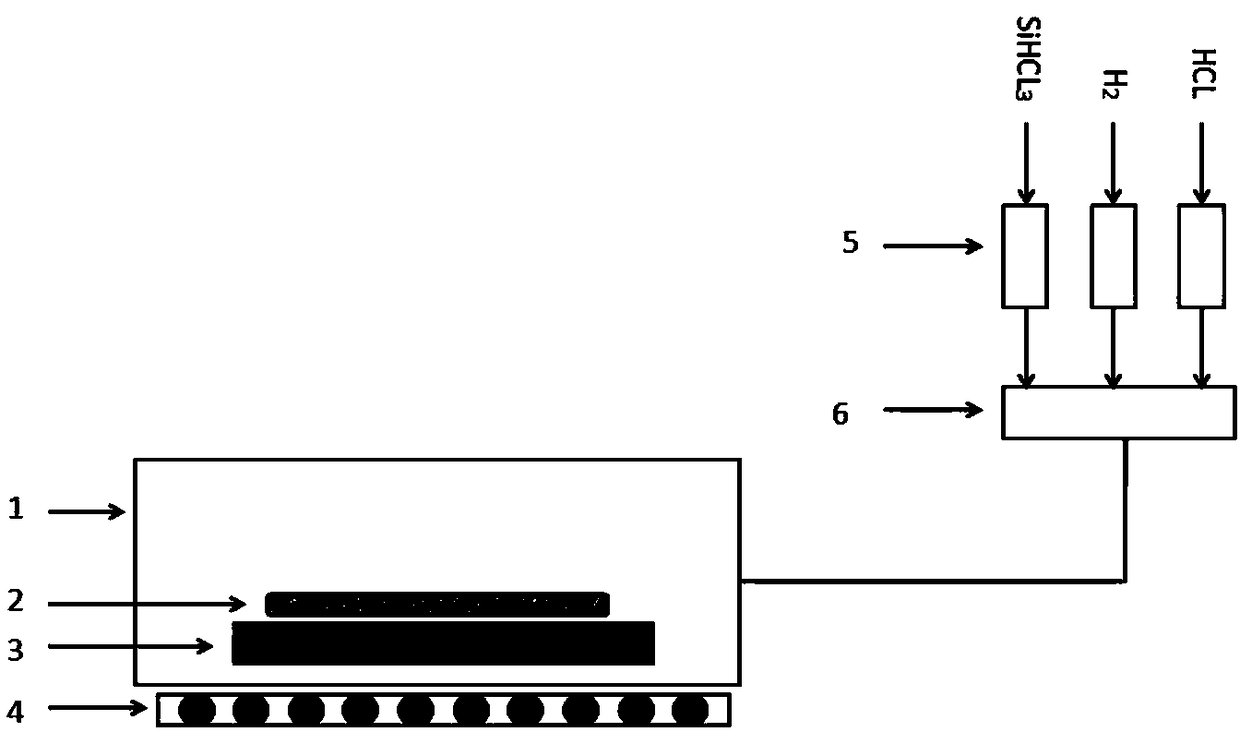

[0026] A kind of preparation method of phosphorus-doped silicon epitaxial wafer for 200mm Schottky tube of the present invention comprises the following steps:

[0027] A. Prepare phosphorus-doped silicon substrate: In order to ensure the requirement of conduction voltage drop, choose phosphorus-doped silicon substrate with a resistivity of 0.0012~0.0015Ωcm. In order to ensure the requirements of STEP lithography machine and the integrity of chip graphics, the substrate Local flatness ≤0.8μm (25mm×25mm), in order to reduce the diffusion of substrate impurities, the back seal layer is silicon dioxide + polysilicon, the thickness of silicon dioxide and polysilicon is

[0028] B. Reaction chamber and substrate cleaning: remove surface impurities and deposited polysilicon layer in epitaxy equipment before epitaxy;

[0029] C. Graphite pedestal treatment: Before epitaxial growth, the pedestal must undergo vapor phase etching treatment again to remove impurities on the surface of ...

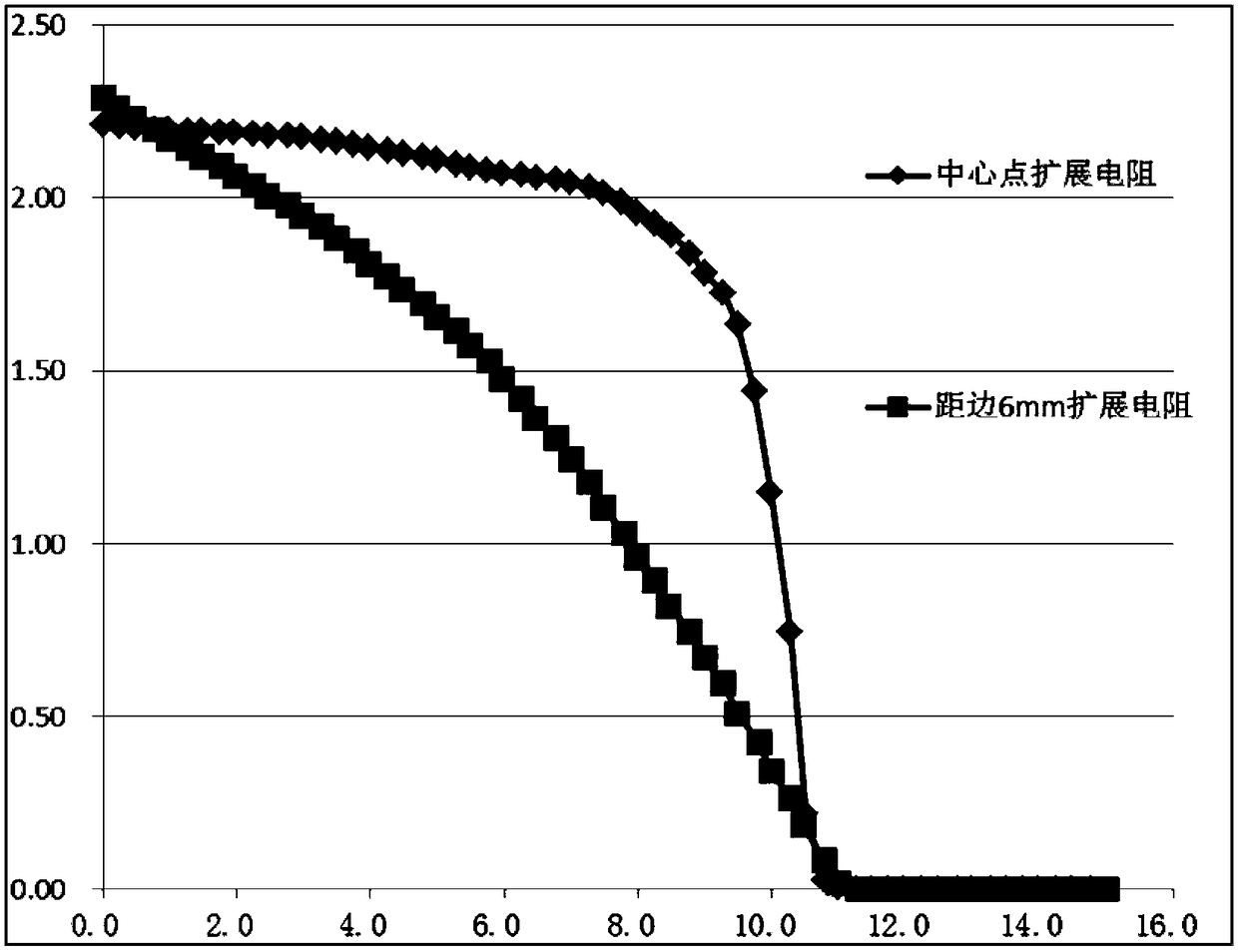

Embodiment 1

[0035] A kind of preparation method of phosphorus-doped silicon epitaxial wafer for 200mm Schottky tube of the present invention comprises the following steps:

[0036] A. Prepare phosphorus-doped silicon substrate: choose phosphorus-doped silicon substrate, resistivity 0.0012~0.0015Ωcm, local flatness of substrate ≤0.8μm (25mm×25mm), back seal layer is silicon dioxide + polysilicon, dioxide The thickness of both silicon and polysilicon is

[0037] B. Reaction chamber and substrate cleaning: remove surface impurities and deposited polysilicon layer in epitaxy equipment before epitaxy;

[0038] C. Graphite pedestal treatment: Before epitaxial growth, the pedestal must be reprocessed to remove impurities on the surface of the pedestal and deposited polysilicon layer;

[0039] C. The first layer of encapsulation layer: load a phosphorus-doped silicon substrate, grow a layer of encapsulation layer with a thickness of 0.7 μm on the surface and edge of the substrate, and at the s...

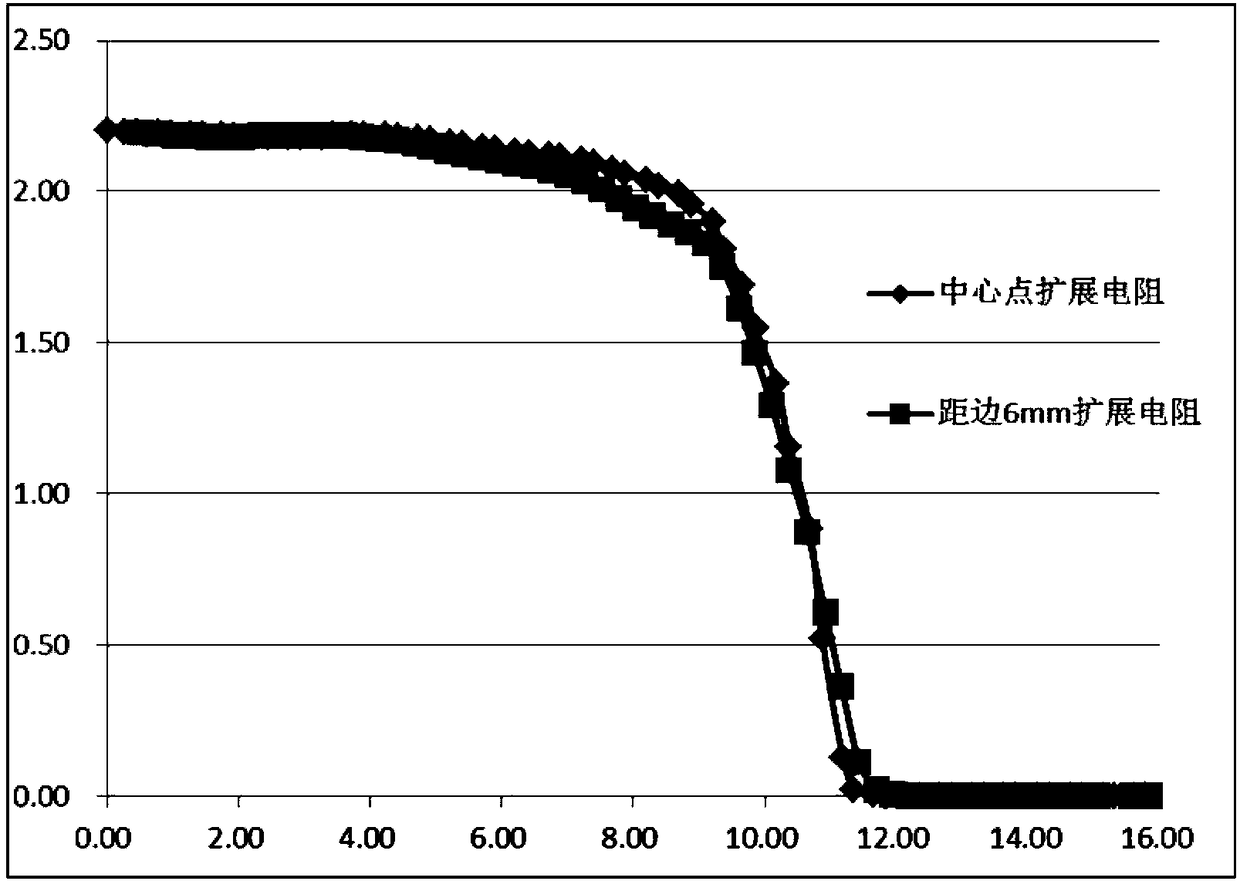

Embodiment 2

[0045] A kind of preparation method of phosphorus-doped silicon epitaxial wafer for 200mm Schottky tube of the present invention comprises the following steps:

[0046] A. Prepare phosphorus-doped silicon substrate: choose phosphorus-doped silicon substrate, resistivity 0.0012~0.0015Ωcm, local flatness of substrate ≤0.8μm (25mm×25mm), back seal layer is silicon dioxide + polysilicon, dioxide The thickness of both silicon and polysilicon is

[0047] B. Reaction chamber and substrate cleaning: remove surface impurities and deposited polysilicon layer in epitaxy equipment before epitaxy;

[0048] C. Graphite pedestal treatment: Before epitaxial growth, the pedestal must undergo vapor phase etching treatment again to remove impurities on the surface of the pedestal and deposited polysilicon layer;

[0049] C. The first layer of encapsulation layer: load a phosphorus-doped silicon substrate, grow a layer of encapsulation layer with a thickness of 0.5 μm on the surface and edge o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com