Water-proof and oxygen-permeable layer of metal air battery based on perfluorocarbon

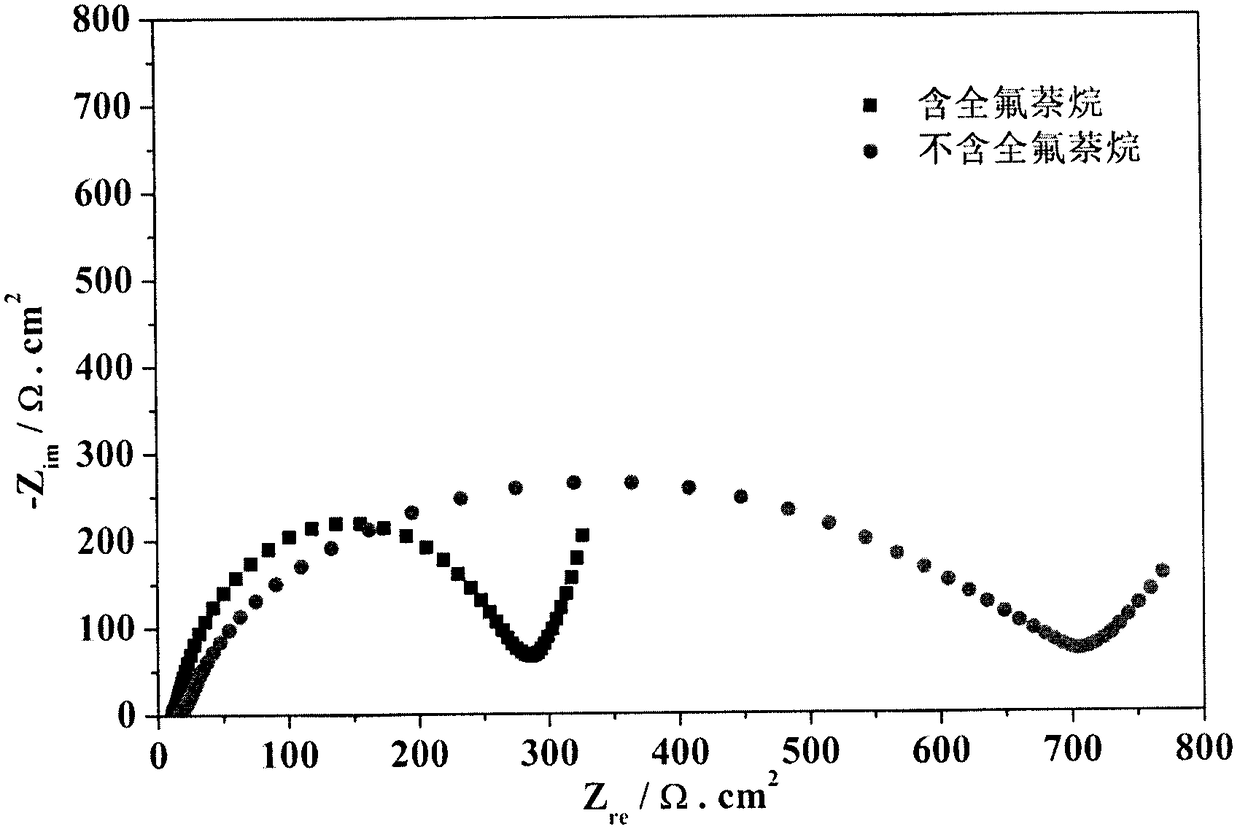

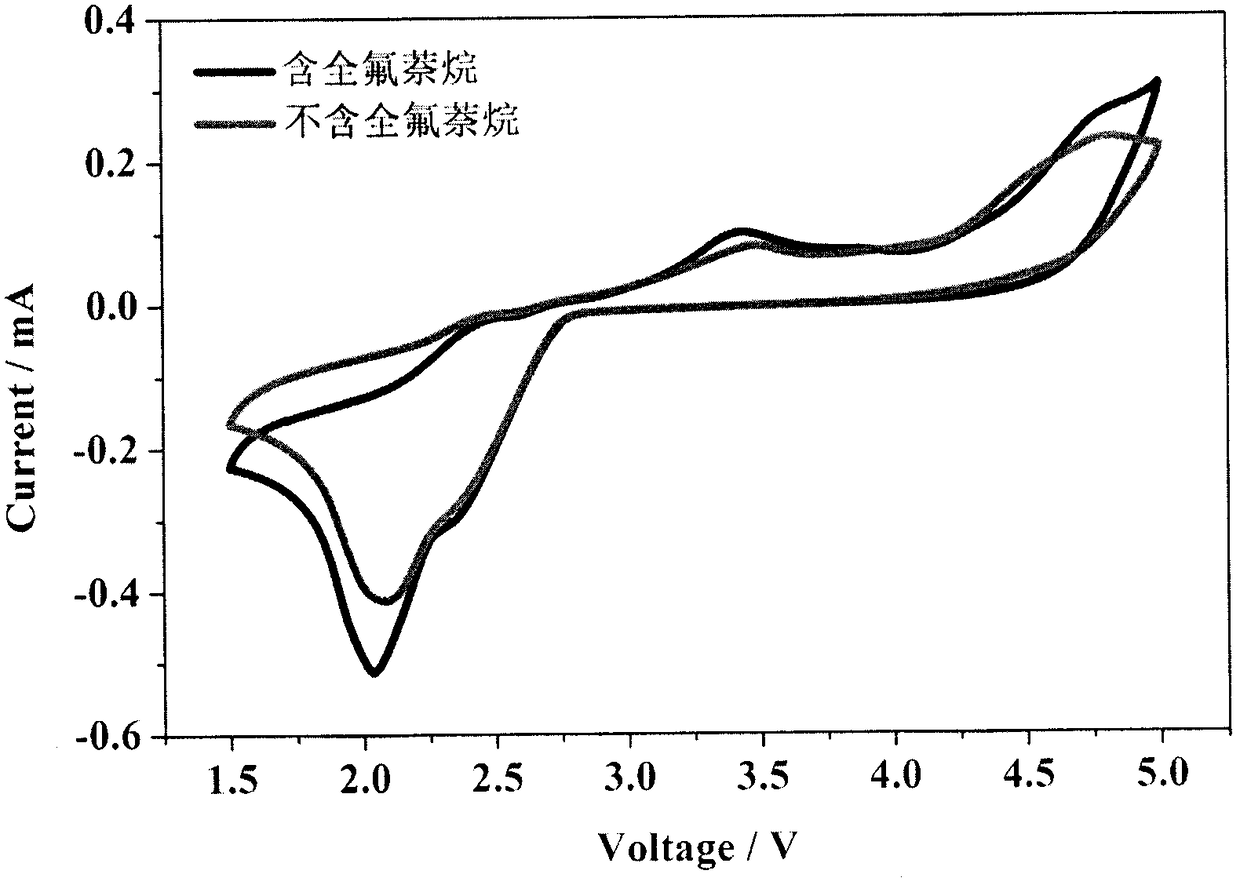

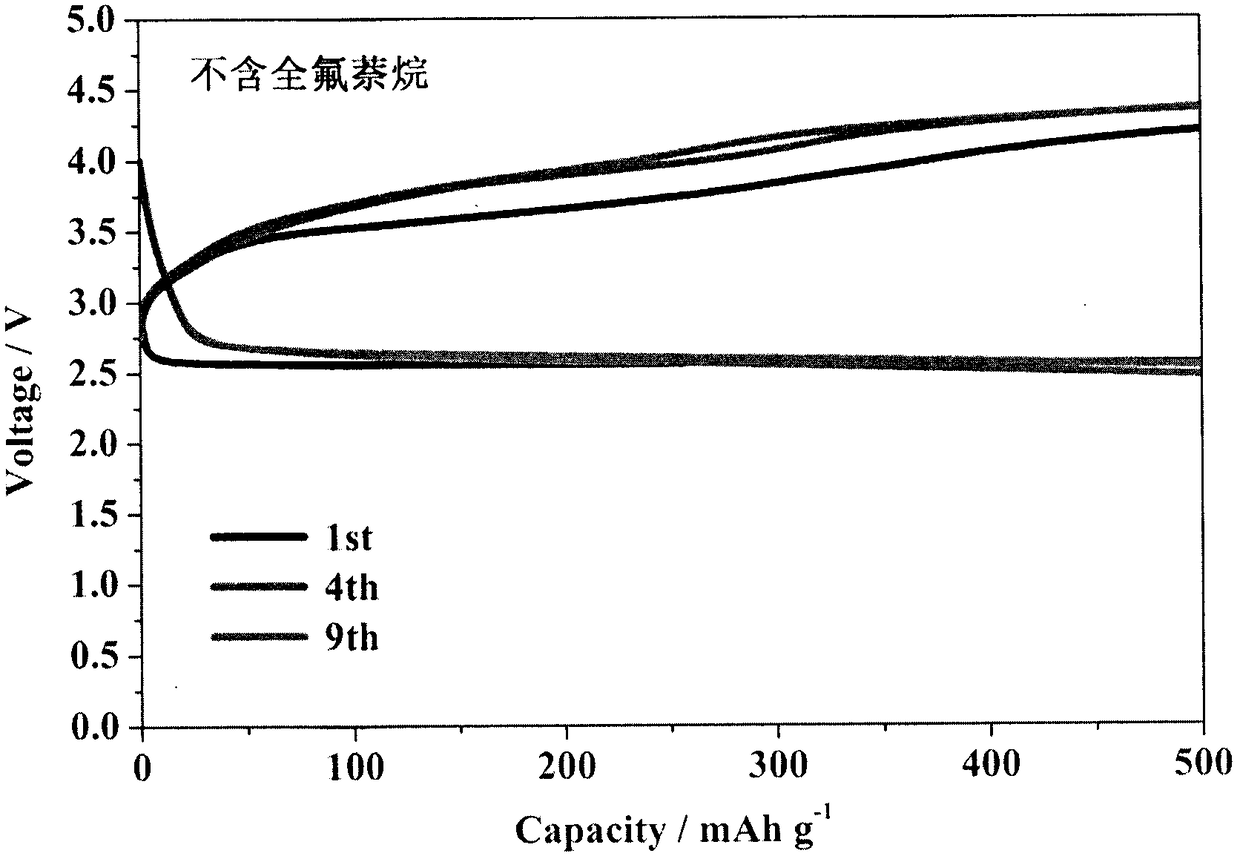

A metal-air battery, waterproof and oxygen-permeable layer technology, applied in fuel cell half-cells and primary battery-type half-cells, etc., can solve problems affecting battery cycle performance, oxygen mass transfer polarization, metal negative electrode corrosion, etc. Achieve the effects of improving oxygen transmission capacity, preventing H2O and CO2 from entering, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 60% PTFE solution, add absolute ethanol to dilute it into 5%-30% PTFE solution, and brush the diluted PTFE solution on one side of the nickel foam with a thickness of 0.5-1mm and a diameter of 8-20mm. Dry at ~80°C for 5-60 minutes, brush again, and repeat this many times. Then put the nickel foam into a tube furnace for sintering at 200-350°C for 0.5-2 hours. Finally, apply a layer of perfluorodecalin or perfluorooctane (10-200 μL) by spraying, dripping or other methods to obtain a waterproof and oxygen-permeable layer.

Embodiment 2

[0021] Put conductive carbon material (KB, Super P, acetylene black, etc.) and PTFE solution in a beaker at a ratio of 6:4 to 9:1, add absolute ethanol and isopropanol, and perform ultrasonic stirring for 1 to 10 hours until the formation of viscous. Then roll it into a film with a pair of rollers, with a thickness of 0.5-2 mm. Afterwards, the film is put into a tube furnace for sintering at 200-350°C for 0.5-2 hours. Finally, apply a layer of perfluorodecalin or perfluorooctane (10-200 μL) by spraying, dripping or other methods to obtain a waterproof and oxygen-permeable layer.

Embodiment 3

[0023] Assemble lithium-air batteries in a glove box filled with argon, and the electrolyte is 0.5-2M lithium bistrifluoromethanesulfonimide (LiTFSI), or lithium trifluoromethanesulfonate (LiTf), or LiNO 3 , or LiClO 4 Soluble in solvents such as ethylene glycol dimethyl ether (DME), tetraethylene glycol dimethyl ether (TEGDME) or dimethyl sulfoxide (DMSO). The air electrode is a conductive carbon material (KB, SuperP, acetylene black, etc.) and an oxygen electrode catalyst (metal oxide, carbide, noble metal, etc.). The diaphragm is glass fiber filter paper, and the negative electrode material is lithium sheet with a diameter of 8-12 mm. The specific operation steps are: put the waterproof and oxygen-permeable layer into the positive electrode shell, then put the air electrode and diaphragm, add the electrolyte dropwise, then put the lithium sheet, gasket, shrapnel in sequence, and finally put the negative electrode shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com