Fibrous carbon nanostructure dispersion

A nanostructure, fibrous carbon technology, applied in nanostructure manufacturing, carbon nanotubes, nanocarbons, etc., can solve problems such as poor handling and processability, and achieve the effect of excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

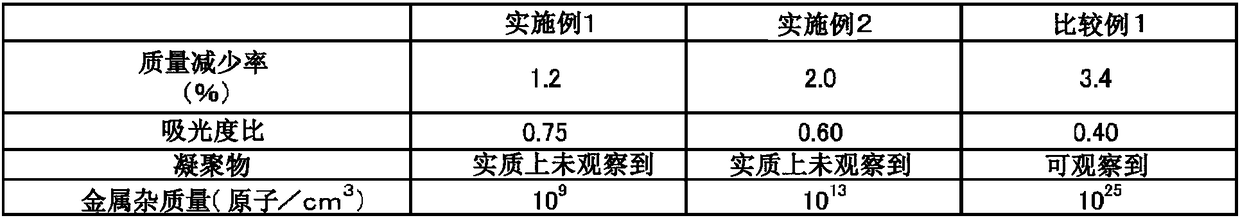

Examples

Embodiment 1

[0149]

[0150] According to the super growth method described in Japanese Patent No. 4621896, SGCNTs as fibrous carbon nanostructures were synthesized under the following conditions.

[0151] Raw material carbon compound: ethylene; supply speed 50sccm

[0152] Atmosphere: helium / hydrogen mixed gas; supply speed 1000sccm

[0153] ·Pressure: 1 atmosphere

[0154] ·Water vapor addition amount: 300ppm

[0155] ·Reaction temperature: 750℃

[0156] Response time: 10 minutes

[0157] Metal catalyst: iron thin film (thickness 1nm)

[0158] ·Substrate: silicon wafer.

[0159] Dissolve 1 g of the obtained SGCNT in 250 mL of 7.7 M HNO 3 Stir in the middle for 8 hours, and reflux at 125°C for 12 hours for purification. Then, 1800 mL of deionized water was added, and after ultrasonic treatment at 40 kHz for 60 minutes using an ultrasonic irradiation machine (manufactured by Honda Electronics, product name "WTC-1200-40"), cross-flow filtration was performed using a 0.02 μm ceramic...

Embodiment 2

[0161] A fibrous carbon nanostructure dispersion was obtained in the same manner as in Example 1, except that the synthesis reaction time of the fibrous carbon nanostructure SGCNT was 15 minutes. The obtained fibrous carbon nanostructure dispersion was 90 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com