Feed additive capable of preventing and treating livestock and poultry diseases

A technology for feed additives and livestock and poultry diseases, applied in the direction of diseases, animal feed, antiviral agents, etc., can solve the problems of drug resistance, residues, hidden dangers of food safety, etc., to promote growth, improve release, conditioning and The effect of restoring immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

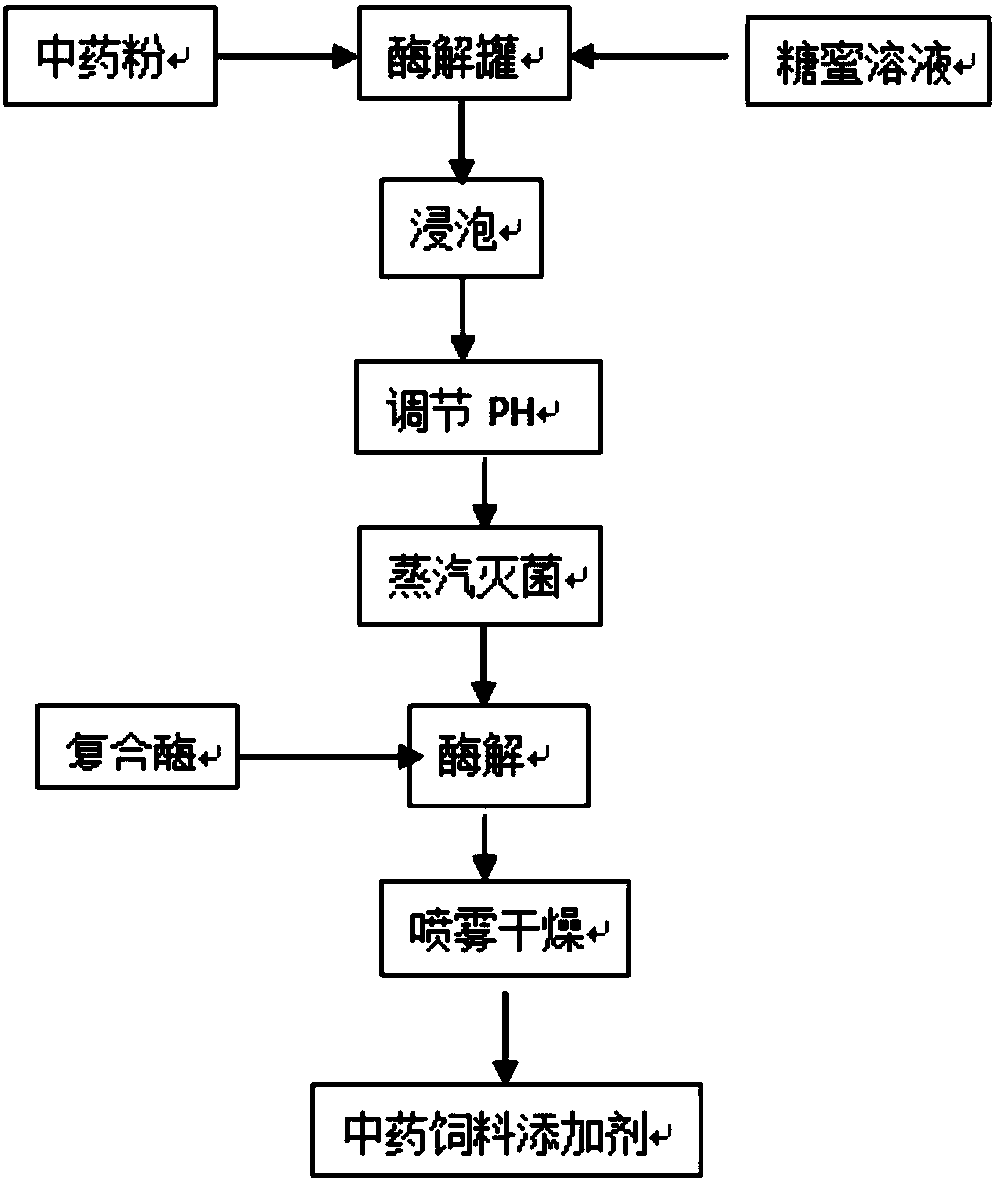

Method used

Image

Examples

Embodiment 1

[0037] The traditional Chinese medicine components and their mass parts are: 35 parts of eucommia leaves, 30 parts of Sichuan cinnamon bark, and 35 parts of wintergreen leaves. Pretreatment of Chinese herbal medicines:

[0038] Dry all the traditional Chinese medicines at 40-50 degrees until the water content is less than 10%, crush them through a 120-mesh sieve, and mix the sieved Chinese medicines evenly according to the ratio of parts by mass;

[0039] Molasses pretreatment:

[0040] Dilute the molasses with 65% solid content and 25% sucrose content with drinking water into a molasses solution with a mass concentration of 20% for subsequent use;

[0041] Preparation of complex enzymes:

[0042] Mix cellulase, hemicellulase, pectinase and fructosyltransferase in a mass ratio of 1:0.8:0.2:0.8 and set aside;

[0043] Enzymolysis:

[0044] Put the mixed traditional Chinese medicine powder into the fermenter, add molasses solution until the water content of the system is 50%...

Embodiment 2

[0046] The preparation method and steps of the Chinese medicine, molasses and fermentation enzyme of embodiment 2 are the same as embodiment 1;

[0047] Enzymolysis:

[0048] Put the mixed traditional Chinese medicine powder into a fermenter, add molasses solution until the water content of the system is 60%, soak for 2 hours, adjust the pH value to 5.5, and steam sterilize at 121°C for 20 minutes. After cooling, add 1.25% of the traditional Chinese medicine compound Enzyme, 4 hours of enzymolysis at 35-40°C, 10 hours of enzymolysis at 40-45°C, 10 hours of enzymolysis at 45-50°C, stirring once every 1 hour; after the end of the enzymolysis, spray drying to obtain the feed additive.

Embodiment 3

[0050] The preparation method and steps of the Chinese medicine, molasses and fermentation enzyme of embodiment 2 are the same as embodiment 1;

[0051] Enzymolysis:

[0052] Put the mixed traditional Chinese medicine powder into a fermenter, add molasses solution until the water content of the system is 70%, soak for 2 hours, adjust the pH value to 6.0, and steam sterilize at 121°C for 20 minutes. After cooling, add compounded Enzyme, 4 hours of enzymolysis at 35-40°C, 10 hours of enzymolysis at 40-45°C, 10 hours of enzymolysis at 45-50°C, stirring every 1 hour, after the end of enzymolysis, spray drying to obtain the feed additive.

[0053] The feed additive prepared by the above method was used for experiment.

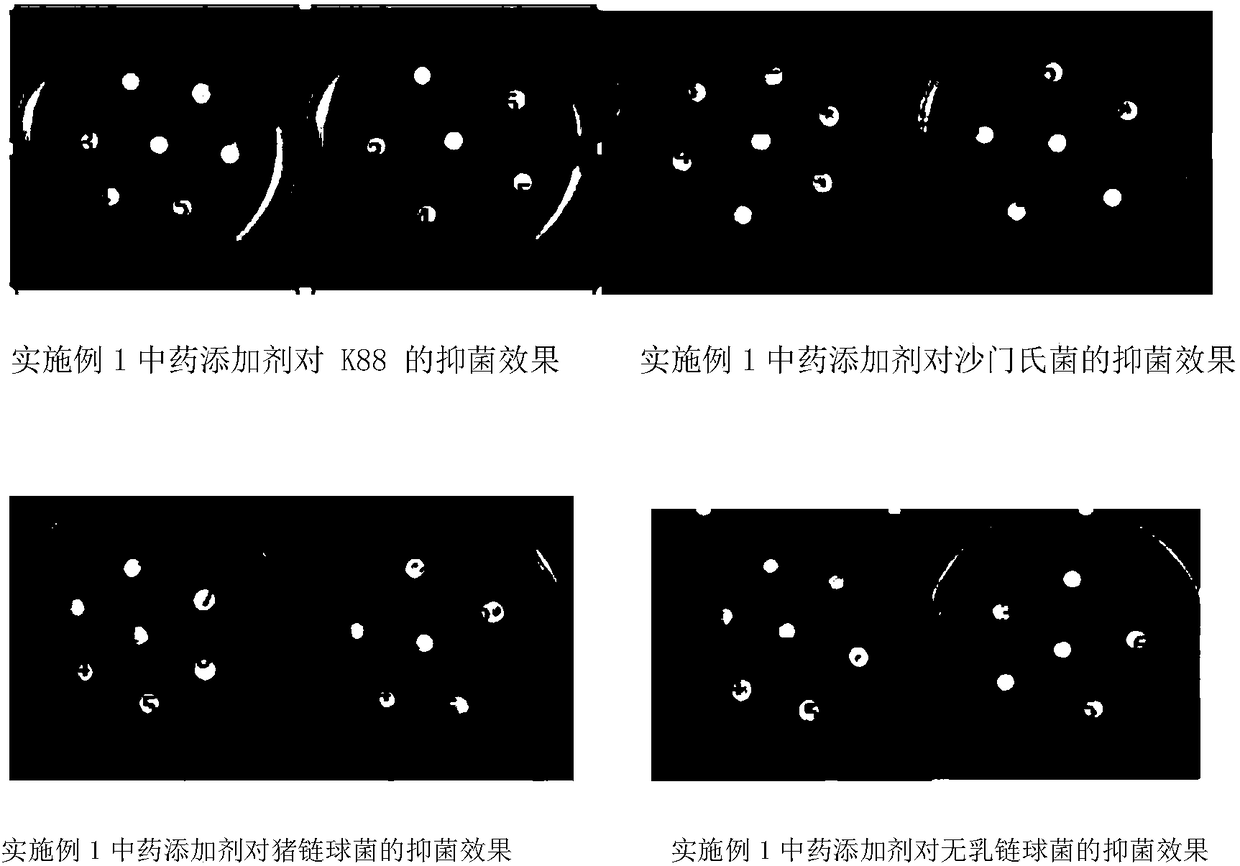

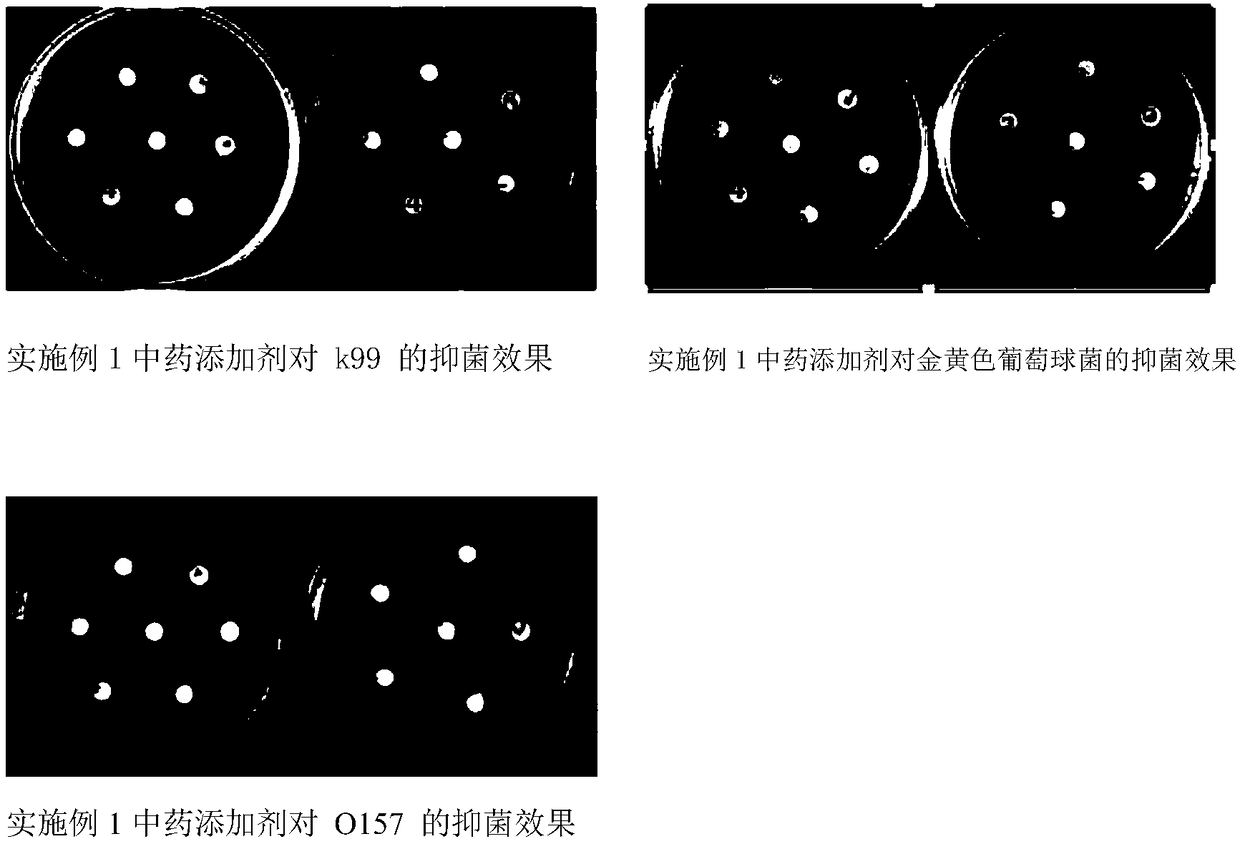

[0054] 1. Antibacterial test in vitro:

[0055] Table 1 Bacterial strains used in antibacterial experiments

[0056]

[0057]

[0058] Table 2 In vitro antibacterial test bacterial species and the control group drugs used by the disk method

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com