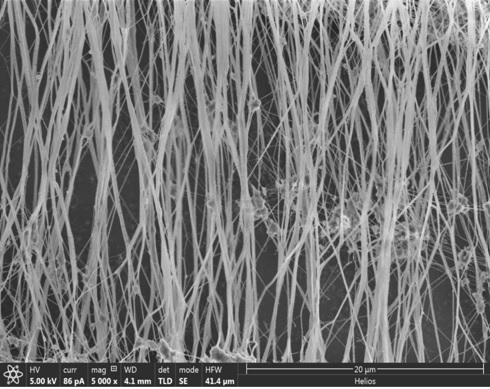

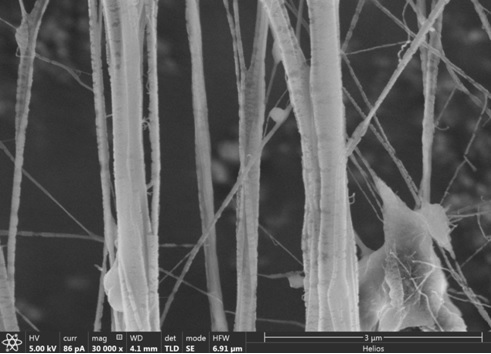

Efficient antibacterial polytetrafluoroethylene microporous membrane and preparation method thereof

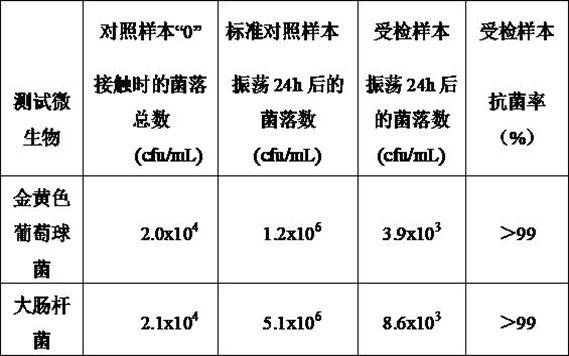

A technology of polytetrafluoroethylene and microporous membrane, which is applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of limited bactericidal effect, poor bactericidal effect, and reduced antibacterial property, and achieve excellent deodorization ability, Wide application range and high sterilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A method for preparing a high-efficiency antibacterial polytetrafluoroethylene microporous membrane includes a raw material preparation process and a film forming process.

[0039] The raw material preparation process includes the following steps:

[0040] S11. Add 1-10 parts by weight of zinc ion antibacterial agent to 100 parts by weight of absolute ethanol, mix and stir to obtain mixture A, the stirring time is 30-60 minutes, and the stirring speed is 1000-1500 r / min.

[0041] S12. Add 5-15 parts by weight of the mixture A to 100 parts by weight of the hydrocarbon additive to obtain the mixture B; the stirring time is 5-20 minutes, and the stirring speed is 500-1000 r / min.

[0042] Wherein, the hydrocarbon additives include one or more of isoparaffin, petroleum ether, solvent oil and paraffin oil.

[0043] If the zinc ion antibacterial agent is directly added to the hydrocarbon additive, the zinc ion antibacterial agent will directly precipitate and cannot be mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com