A kind of preparation method of printing and dyeing wastewater rapid decolorizer

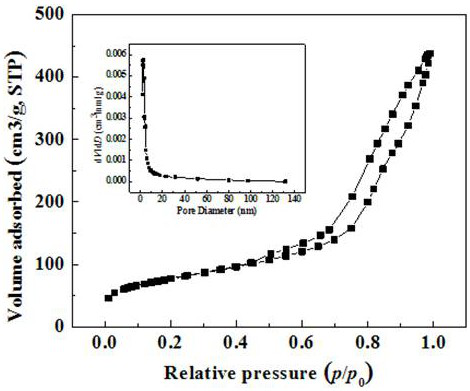

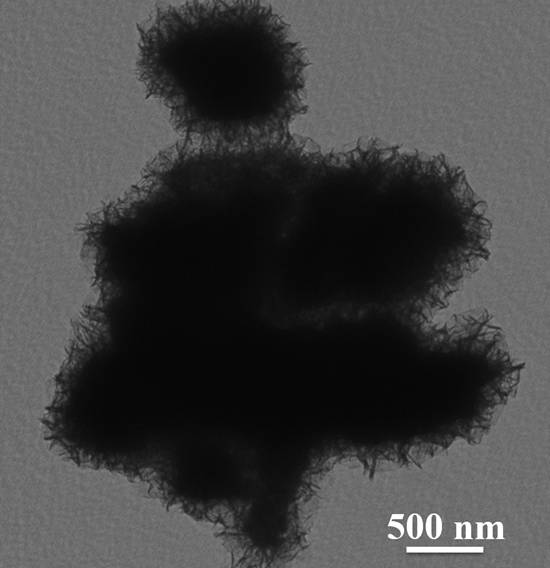

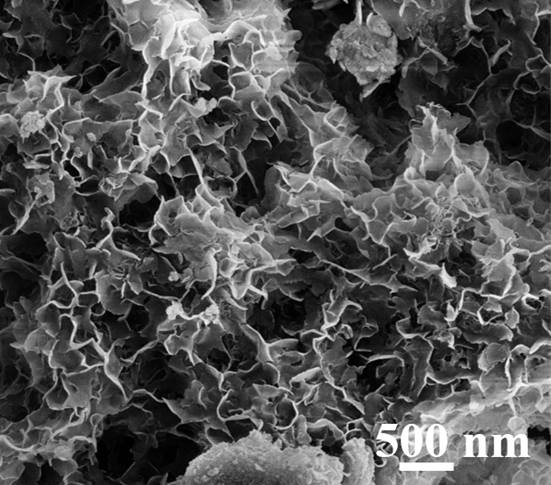

A printing and dyeing wastewater and decolorizing agent technology, applied in chemical instruments and methods, water pollutants, adsorbed water/sewage treatment, etc., can solve the problems of weak adsorption capacity, long adsorption time, limitations, etc., and achieve strong decolorization ability and long decolorization time The effect of short and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the printing and dyeing wastewater quick decolorizer of the present embodiment comprises the following steps:

[0027] (1) Weigh 2.35g of sodium silicate and dissolve it in 50ml of water, then add 3.0g of acetic acid and 0.3g of ammonium fluoride as hydrogenation medium;

[0028] (2) Weigh 3.0g p123 and dissolve it in the mixed solution of step (1), react at 40°C for 24 h under magnetic stirring, and then react at 70°C for 24 h;

[0029] (3) Centrifuge and wash the mixture in step (2), and then calcinate at 550°C for 5 hours;

[0030] (4) Weigh 0.05g of the sample in step (3) and add it to 30ml of metal salt (molar ratio: n(Mg(NO 3 ) 2 : n(Al(NO 3 ) 3 ):n(urea)=3:1:10) solution, stirred for 5min, then reacted at 120℃ for 48h. Centrifuge, wash, and dry to become a decolorizer.

[0031] (5) Weigh 0.025g of decolorizing agent and add it to 25ml of methylene blue solution (wt=0.01%), and carry out decolorization for 5min. The results show tha...

Embodiment 2

[0033] The preparation method of the printing and dyeing wastewater quick decolorizer of the present embodiment comprises the following steps:

[0034] (1) Weigh 2.35g of sodium silicate and dissolve it in 50ml of water, then add 3.0g of acetic acid and 0.3g of ammonium fluoride as hydrogenation medium;

[0035] (2) Weigh 3.0g p123 and dissolve it in the mixed solution of step (1), react under magnetic stirring at 40°C for 24h, then react at 70°C for 24h;

[0036] (3) Centrifuge and wash the mixture in step (2), and then calcinate at 550°C for 5 hours;

[0037] (4) Weigh 0.05g of the sample in step (3) and add it to 30ml of metal salt (molar ratio: n(Mg(NO 3 ) 2 : n(Al(NO 3 ) 3 ):n(urea)=3:1:10) solution, stirred for 5min, then reacted at 120℃ for 48h. Centrifuge, wash, and dry to become a decolorizer.

[0038] (5) Weigh 0.025g of decolorizing agent and add it to 25ml of rhodamine solution (wt=0.01%), and carry out decolorization for 5min. The results show that the solut...

Embodiment 3

[0040] (1) Weigh 2.35g of sodium silicate and dissolve it in 50ml of water, then add 3.0g of acetic acid and 0.3g of ammonium fluoride as hydrogenation medium;

[0041] (2) Weigh 3.0g p123 and dissolve it in the mixed solution of step (1), react under magnetic stirring at 40°C for 24h, then react at 70°C for 24h;

[0042] (3) Centrifuge and wash the mixture in step (2), and then calcinate at 550°C for 5 h;

[0043] (4) Weigh 0.05g of the sample in step (3) and add it to 30ml of metal salt (molar ratio: n(Mg(NO 3 )2 : n(Al(NO 3 ) 3 ):n(urea)=3:1:10) solution, stirred for 5min, then reacted at 120℃ for 48h. Centrifuge, wash, and dry to become a decolorizer.

[0044] (5) Weigh 0.025g of decolorizing agent and add it to 25ml of Coomassie Brilliant Blue solution (wt=0.01%), and carry out decolorization for 5min. The results show that the solution is clear and transparent after decolorization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com