High-efficiency and low-cost cement grinding aid and preparation method thereof

A cement grinding aid, low-cost technology, applied in the preparation of cement grinding aid, low-cost cement grinding aid, high-efficiency field, can solve the problem of affecting the service life of buildings, affecting the quality of land water quality, and the improvement effect is not obvious and other problems, to achieve the effect of inhibiting agglomeration, solving processing problems, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

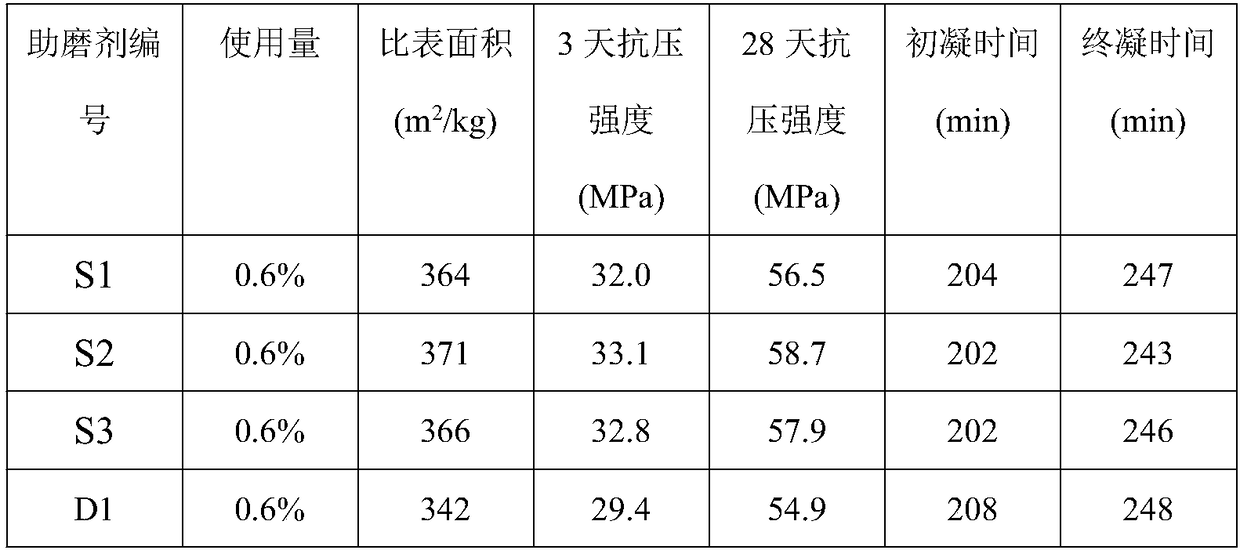

Examples

preparation example Construction

[0031] The preparation method of above-mentioned efficient and low-cost cement grinding aid comprises the steps:

[0032] (a) Get the waste paper pulp wastewater produced by the paper mill, remove chloride ions therein by ion exchange resin, then measure the pH value, add a pH regulator to pH=7, and finally adjust its Baume degree to be 16~20°Bé;

[0033] (b) Accurately weigh each substance for subsequent use according to the amount of each substance in the above-mentioned high-efficiency and low-cost cement grinding aid;

[0034] (c) Add triethanolamine and polyether polyol to an appropriate amount of distilled water, stir evenly with magnetic force while raising the temperature to 40-50°C, then add sodium thiosulfate to dissolve evenly, finally add molasses, stir evenly and maintain at 40°C 50°C for use;

[0035] (d) Add anhydrous sodium acetate and polyhydroxy carboxylic acid to the remaining distilled water, add air-entraining agent after stirring, stir evenly, finally ad...

Embodiment 1

[0039] The pulp wastewater from the paper mill was determined to be alkaline, and its main components were lignin derivatives, organic salts, sodium sulfide, sodium hydroxide, hypochlorite, etc. First, the pulp wastewater is treated with 732 cation exchange resin to remove chloride ions, and then according to its pH value, acetic acid is added dropwise in a titration method until pH = 7, and distilled water is added to the titrated pulp wastewater to adjust its Baume degree to 16. °Bé;

[0040] Weigh 6kg of triethanolamine, 3kg of molasses, 5kg of polyether polyol, 30kg of treated pulp wastewater, 7kg of sodium thiosulfate, 3kg of anhydrous sodium acetate, 4kg of sodium lignosulfonate, 6kg of citric acid, and 36L of distilled water;

[0041] Take 10L of water, add the weighed triethanolamine and polyether polyol into it, heat up to 40°C while magnetically stirring evenly, then add sodium thiosulfate to dissolve evenly, finally add molasses, stir evenly and maintain at 40°C unt...

Embodiment 2

[0045] The operation is the same as in Example 1, wherein the difference is: take by weighing 8kg of triethanolamine, 5kg of molasses, 7kg of polyether polyol, 24kg of treated pulp wastewater, 10kg of sodium thiosulfate, 2kg of anhydrous sodium acetate, 2kg of triterpene saponins, Citric acid 4kg, distilled water 38L.

[0046] According to the preparation method of Example 1, cement grinding aid S2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com