Preparation method of functionalized graphene oxide containing phosphorus and silicon

A graphene and functionalization technology, applied in the field of preparation of phosphorus-containing silicon-functionalized graphene oxide, can solve the problems of reduced total heat release, increased initial thermal degradation temperature, unsuitable for industrial applications, etc., and achieves improved thermal stability. properties, mild reaction conditions, and the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

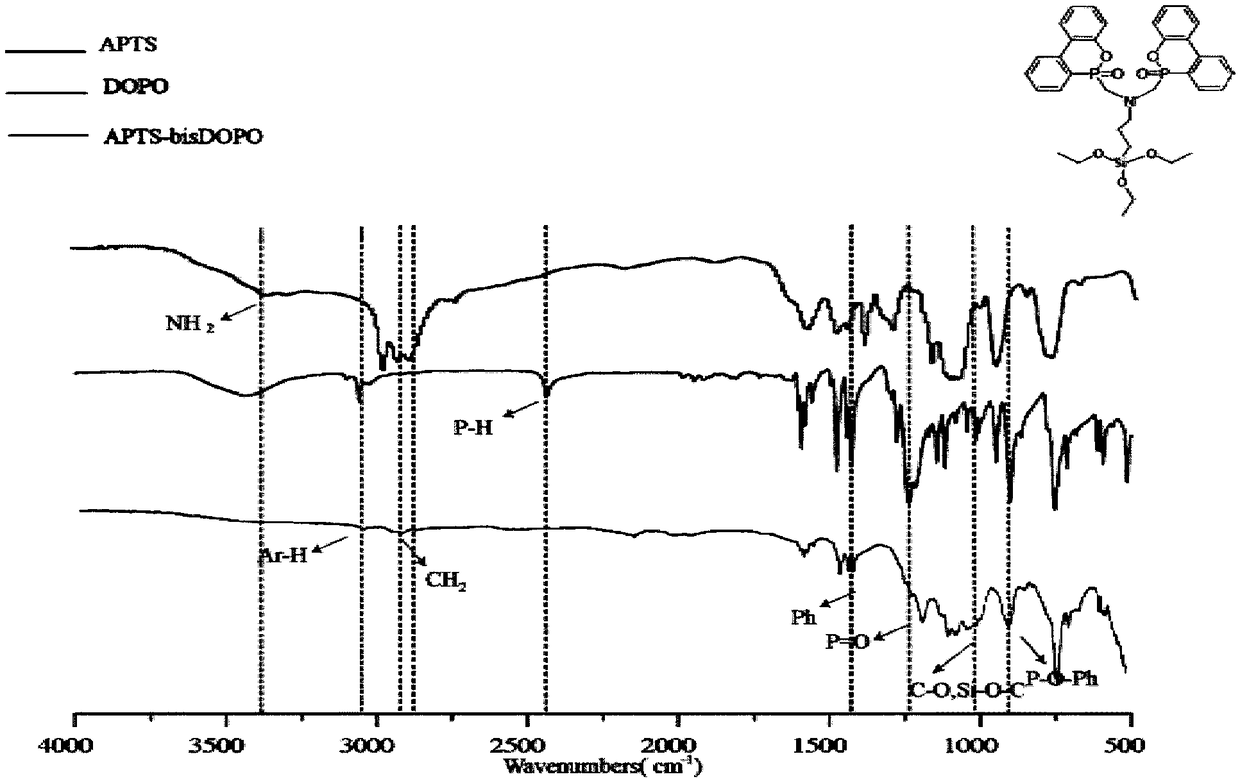

[0026] (1) Synthesis of phosphorus-containing silicon element compounds In a 50mL reaction vessel, add 2.27g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1.11g of γ-aminopropyl tris Ethoxysilane and 0.32 g of paraformaldehyde were dissolved in 30 mL of chloroform, and stirred and reacted at a reaction temperature of 60° C. for 24 h under nitrogen protection. After the reaction, the reaction solution was precipitated and purified in n-hexane to obtain the following figure 1 The phosphorus-containing silicon element compound shown.

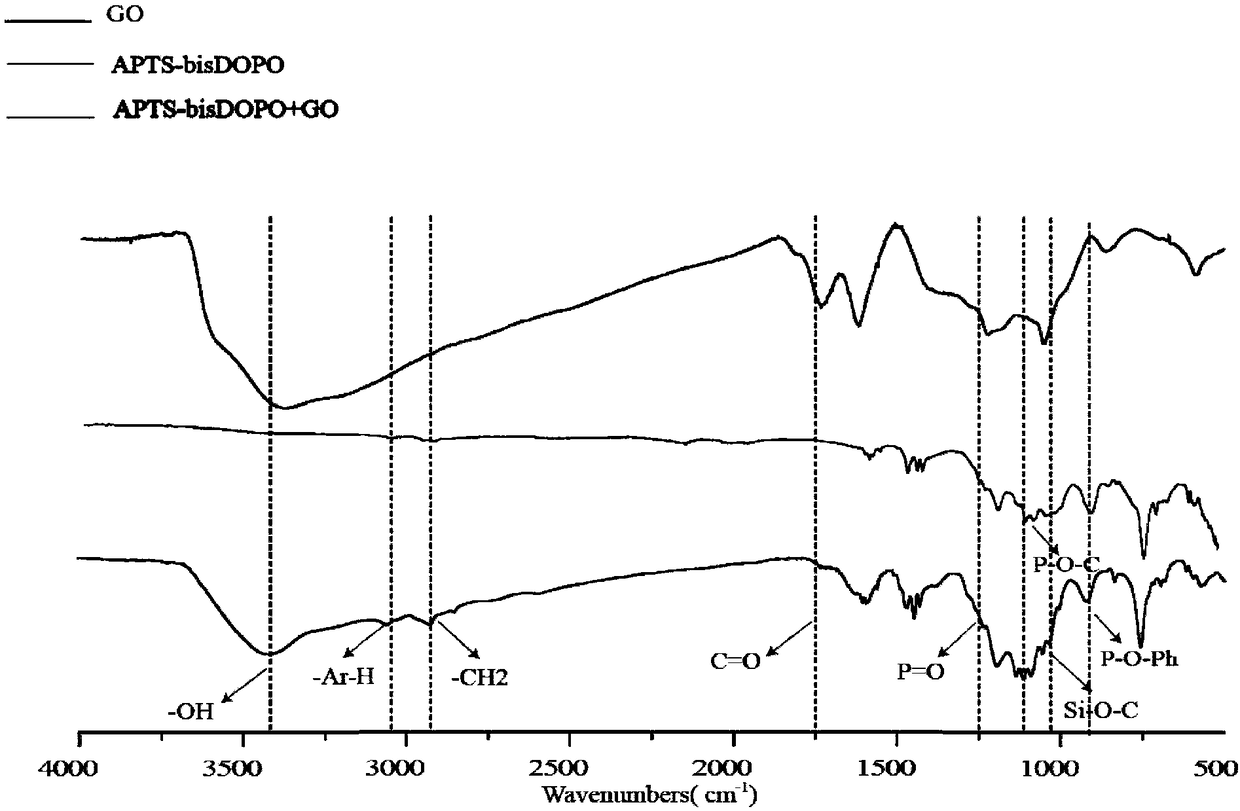

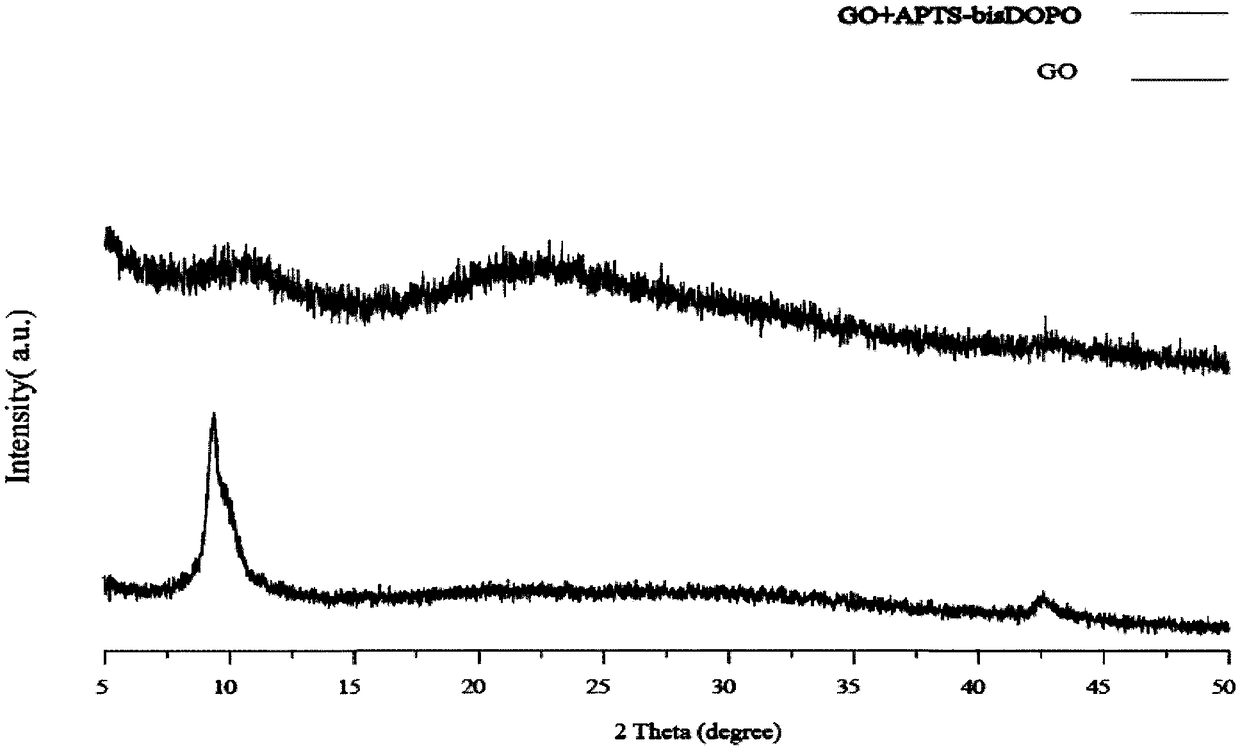

[0027] (2) Synthesis of phosphorus-containing silicon functionalized graphene oxide

[0028] Dissolve 20 mg of graphene oxide in a mixed solution of 10 mL of deionized water and 40 mL of absolute ethanol. After ultrasonication for 60 min, add 0.34 g of phosphorus-containing silicon element compound diluted with 10 mL of toluene drop by drop, and react with stirring at 78°C for 24 h. After the reaction is finished, the product is washed w...

Embodiment 2

[0030] (1) Synthesis of phosphorus-containing silicon compound

[0031] In a 50 mL reaction vessel, add 2.27 g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1.11 g of γ-aminopropyltriethoxysilane, and 0.56 g of paraformaldehyde Dissolve in 30mL of carbon tetrachloride, and stir for 24h at a reaction temperature of 60°C under nitrogen protection. After the reaction, the reaction liquid was precipitated and purified in n-hexane.

[0032] (2) Synthesis of phosphorus-containing silicon functionalized graphene oxide

[0033] Dissolve 50mg of graphene oxide in 10mL of deionized water and 40mL of N,N-dimethylformamide mixed solution, after ultrasonication for 60min, add 0.25g of phosphorus-containing silicon element compound diluted with 10mL of toluene drop by drop, at 78°C , Stir the reaction for 24h. After the reaction, the product was washed with absolute ethanol and deionized water several times, and then purified by centrifugation and lyophilization to obtain the fo...

Embodiment 3

[0035] (1) Synthesis of phosphorus-containing silicon compound

[0036] In a 50 mL reaction vessel, add 3.14 g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 1.52 g of γ-aminopropyltriethoxysilane, and 0.65 g of paraformaldehyde Dissolve it in 30 mL of chloroform, and stir for 24 h at a reaction temperature of 60° C. under nitrogen protection. After the reaction, the reaction liquid was precipitated and purified in n-hexane.

[0037] (2) Synthesis of phosphorus-containing silicon functionalized graphene oxide

[0038] Dissolve 80 mg of graphene oxide in a mixed solution of 10 mL of deionized water and 80 mL of absolute ethanol. After ultrasonication for 60 min, 0.25 g of phosphorus-containing silicon element compound diluted with 10 mL of toluene is added dropwise, and the reaction is stirred at 80°C for 24 h. After the reaction is finished, the product is washed with absolute ethanol and deionized water several times, and then purified by centrifugation and freeze-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com