An environment-friendly fluorine circuit board conformal paint composition and its preparation method and application

A technology of three anti-paints and compositions, which is applied in the direction of anti-corrosion coatings, fire-resistant coatings, paints containing biocides, etc., and can solve the problems that are difficult to meet, high-standard functional requirements, technical effects need to be improved, and performance has not been effectively improved, etc. problems, to achieve the effect of easy repair, balanced performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

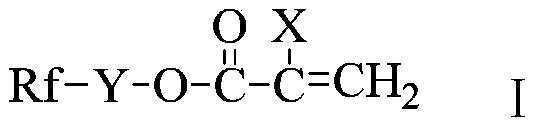

Method used

Image

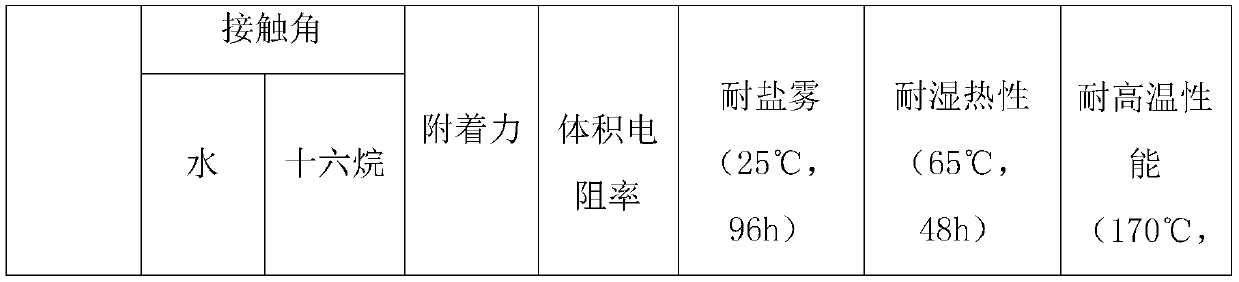

Examples

Embodiment 1

[0047] In a 250mL four-neck flask equipped with a reflux condenser, a thermometer, and replaced with nitrogen, add 5.00g perfluorobutylethyl methacrylate, 3.00g octadecyl acrylate, and 1.50g isobornyl methacrylate Esters, 0.40g glycidyl methacrylate, 0.10g γ-methacryloxypropyl trimethoxysilane, 0.10g azobisisobutyronitrile initiator and 23.33g dearomatization solvent D40, then replace 10 with nitrogen After that, the oil bath was heated to 65°C and reacted for 16 hours. After the reaction was completed, a product with a solid content of 30% was obtained, which was the environmentally friendly fluorine circuit board conformal paint composition.

[0048] The above-mentioned product with a solid content of 30% is diluted with dearomatization solvent D40 to a solid content of 5%, and the diluted treatment solution can be used to directly treat printed circuit boards.

Embodiment 2

[0050] In a 250mL four-necked flask equipped with a reflux condenser, a thermometer, and replaced with nitrogen, add 6.00g of perfluorobutylethyl methacrylate, 2.00g of cetyl acrylate, and 1.50g of isobornyl methacrylate Esters, 0.40g hydroxyethyl methacrylate, 0.10g γ-methacryloxypropyltrimethoxysilane, 0.10g azobisisobutyronitrile initiator and 23.33g dearomatization solvent D40, and then replace 10 with nitrogen After that, the oil bath was heated to 65°C and reacted for 16 hours. After the reaction was completed, a product with a solid content of 30% was obtained, which was the environmentally friendly fluorine circuit board conformal paint composition.

[0051] The product with a solid content of 30% is diluted with dearomatization solvent D40 to a solid content of 6%, and the diluted treatment solution can be used to directly treat printed circuit boards.

Embodiment 3

[0053] In a 250mL four-necked flask equipped with a reflux condenser, a thermometer, and replaced with nitrogen, add 7.00g perfluorobutylethyl methacrylate, 1.00g behenyl acrylate, 1.50g styrene, 0.40 g hydroxypropyl methacrylate, 0.10 g vinyltrimethoxysilane, 0.10 g azobisisobutyronitrile initiator and 23.33 g dearomatization solvent D40, then replace with nitrogen for 10 minutes, then heat the oil bath to 65 °C, After reacting for 16 hours, a product with a solid content of 30% was obtained after the reaction was completed, that is, the environment-friendly fluorine circuit board conformal paint composition was obtained.

[0054] The product with a solid content of 30% is diluted with dearomatization solvent D40 to a solid content of 7%, and the diluted treatment solution can be used to directly treat printed circuit boards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com