Neutron detector based on boron-conversion multi-stage grid gas

A neutron detector and gas technology, applied in the field of nuclear radiation detection, can solve problems such as low gamma suppression ability, low detection efficiency, and small detection area, so as to reduce the number of readout channels, improve neutron conversion efficiency, and increase detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

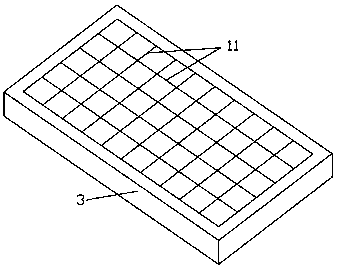

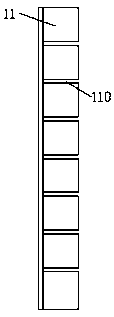

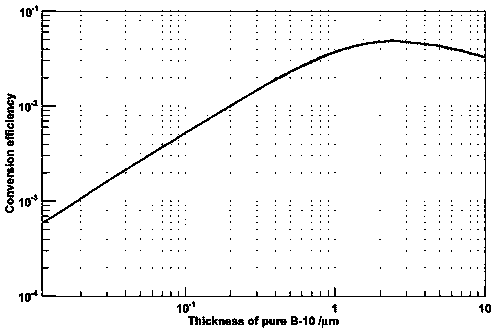

[0034] like Figure 1-2 As shown, a neutron detector based on boron conversion multi-level grid gas, the main structure of the neutron detector adopts boron-plated aluminum strips 11 to form a multi-layer square pipe 1, and the boron-plated raw material adopts Isotopes of Boron 10 B, the isotopes of boron 10 B is a commonly used thermal neutron-sensitive conversion material, its chemical activity is low, it is easy to apply, its content is abundant, and it is easy to obtain concentrated boron ( 10 B abundance 99%), thereby improving the neutron conversion efficiency, it is an ideal solid neutron conversion material; due to the high melting point and non-conductivity of boron, it is difficult to achieve by conventional coating methods, magnetron sputtering as an advanced industrial The coating technology is suitable for the coating of the non-conductive medium with high melting point. The invention uses the method of magnetron sputtering to coat the aluminum substrate with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com