Vertical square column type nanometer thermoelectric power generator for microcontroller

A technology of thermoelectric generators and microcontrollers, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve reliability problems and other problems, and achieve high reliability, high power output, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

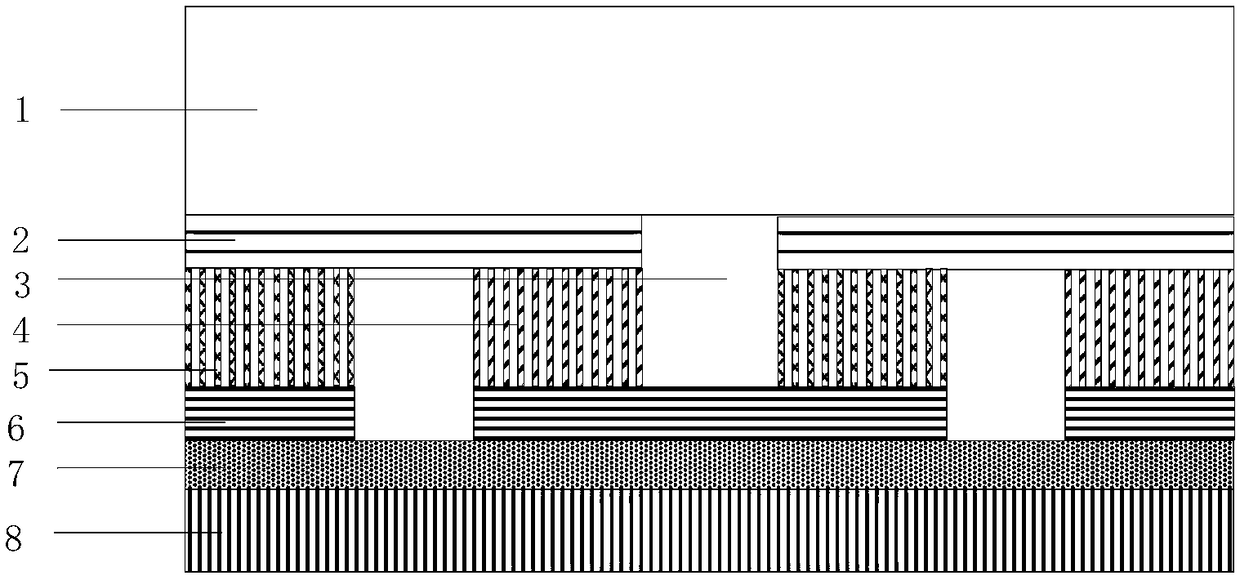

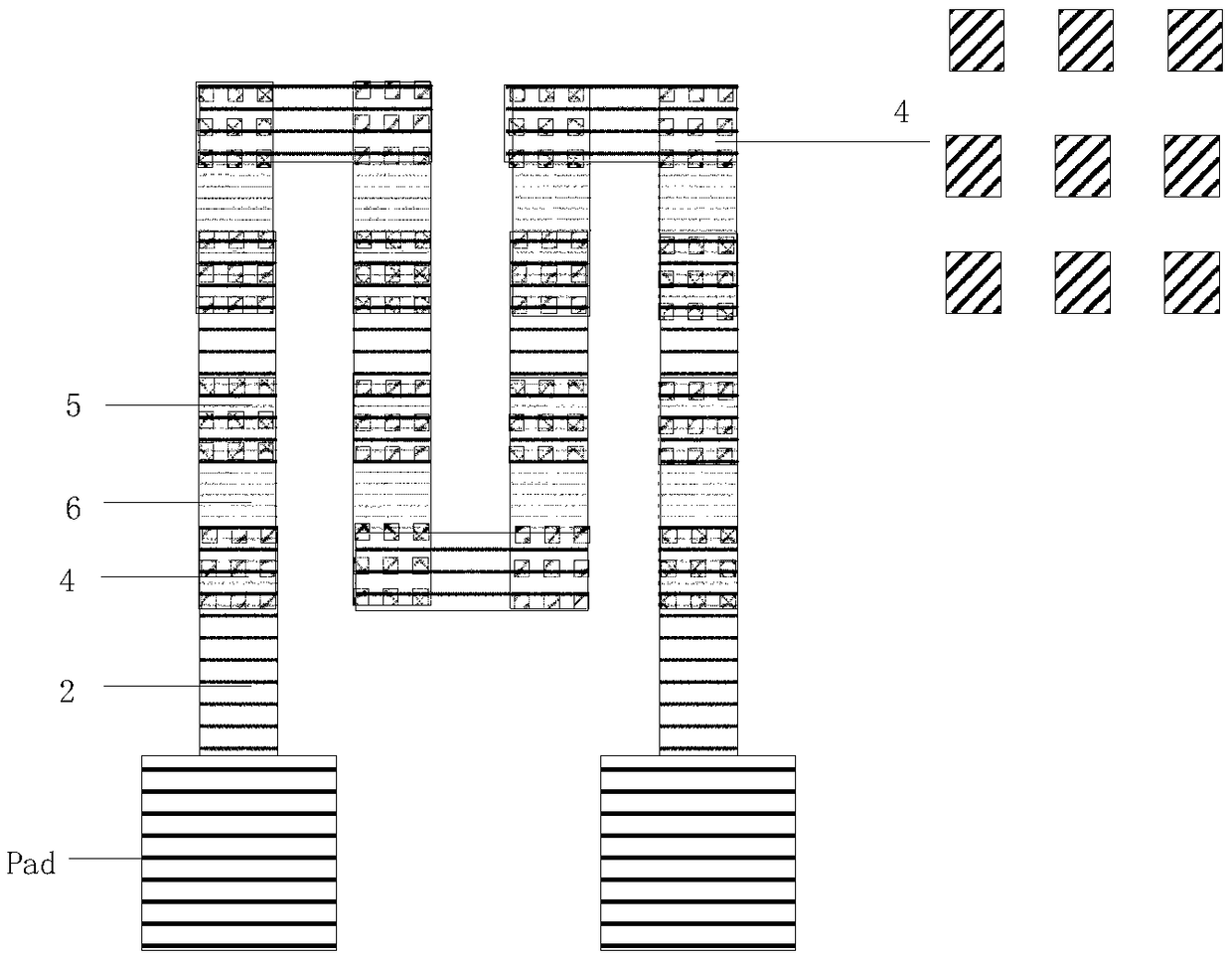

[0018] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0019] See Figure 1-2 , The present invention proposes a vertical square column type nano thermoelectric generator for microcontroller. The N-type silicon substrate 1 is selected with a phosphorus doping concentration of 1.0E15cm-3 and a resistivity of about 2Ωcm. Before fabrication, double-sided polishing is performed, and it is immersed in a 0.55% HF acid solution to remove impurities such as metal particles. Then a tungsten layer with a thickness of 0.15um is sputtered, dry-etched and formed to form the bottom electrode 2 of the thermopile, and then a layer of polyimide layer is spin-coated, and the bottom electrode part is removed and left behind. Used to fill the gap of the lower electrode as a polyimide heat insulation layer 3. Next, a layer of polysilicon with a thickness of 2μm is grown by the LPCVD process, photoresist is coated, and the doping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com