Preparation method of proton exchange membrane fuel cell negative electrode catalyst with defect-structure nitrogen/sulfur co-doped porous carbon aerogel

A defect structure, carbon aerogel technology, applied in the direction of fuel cells, battery electrodes, structural parts, etc., can solve problems such as unsatisfactory catalytic performance, and achieve the effects of high safety, wide source of raw materials, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Configure 200mL of iota-type carrageenan aqueous solution with a mass fraction of 2%, add 4g of urea, cool down after stirring, and obtain a carrageenan-urea hydrogel.

[0025] 2) preparing carrageenan-urea hydrogel into carrageenan-urea aerogel by freeze-drying;

[0026] 3) Carrageenan-urea airgel was calcined at 700°C for 1 hour in a tube furnace under an argon atmosphere to obtain nitrogen / sulfur co-doped carbon airgel;

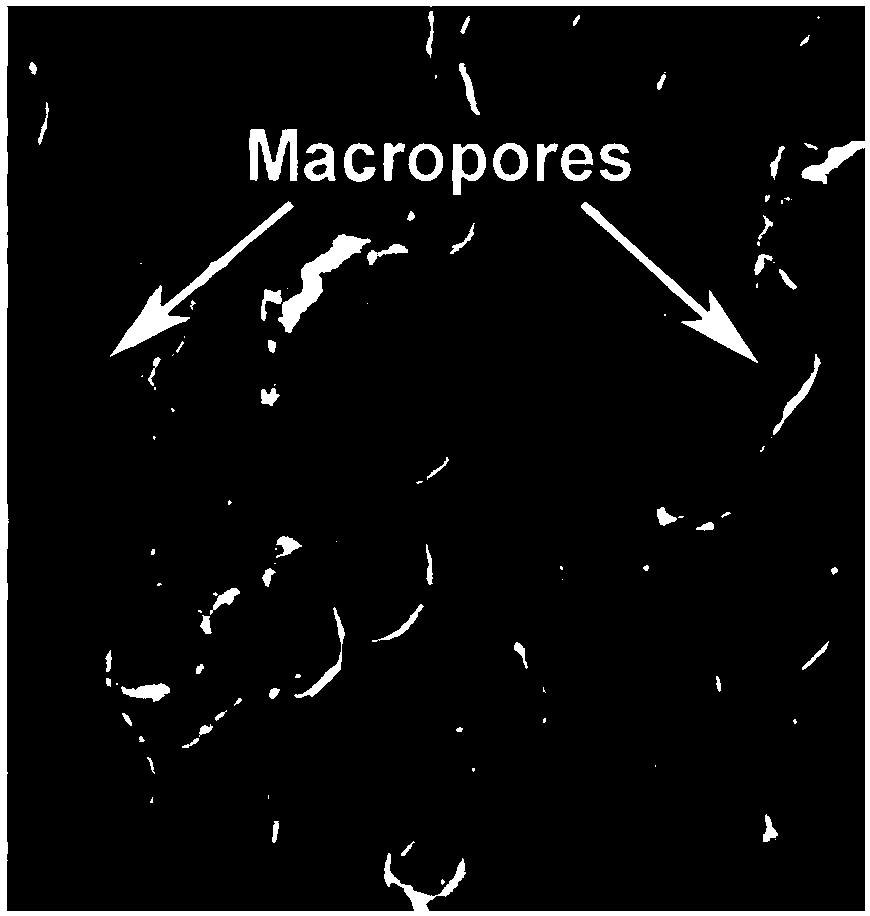

[0027] 4) Remove calcium sulfide, sodium sulfide and other nanoparticles in the nitrogen / sulfur co-doped carbon aerogel with an aqueous hydrochloric acid solution with a concentration of 2M to obtain a nitrogen / sulfur co-doped porous carbon aerogel;

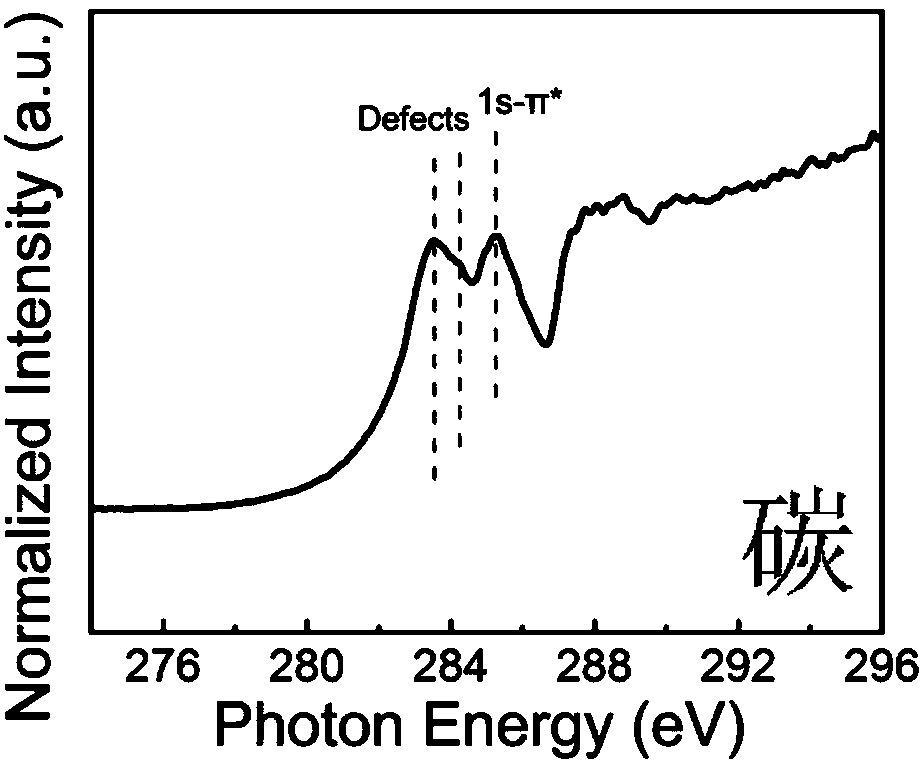

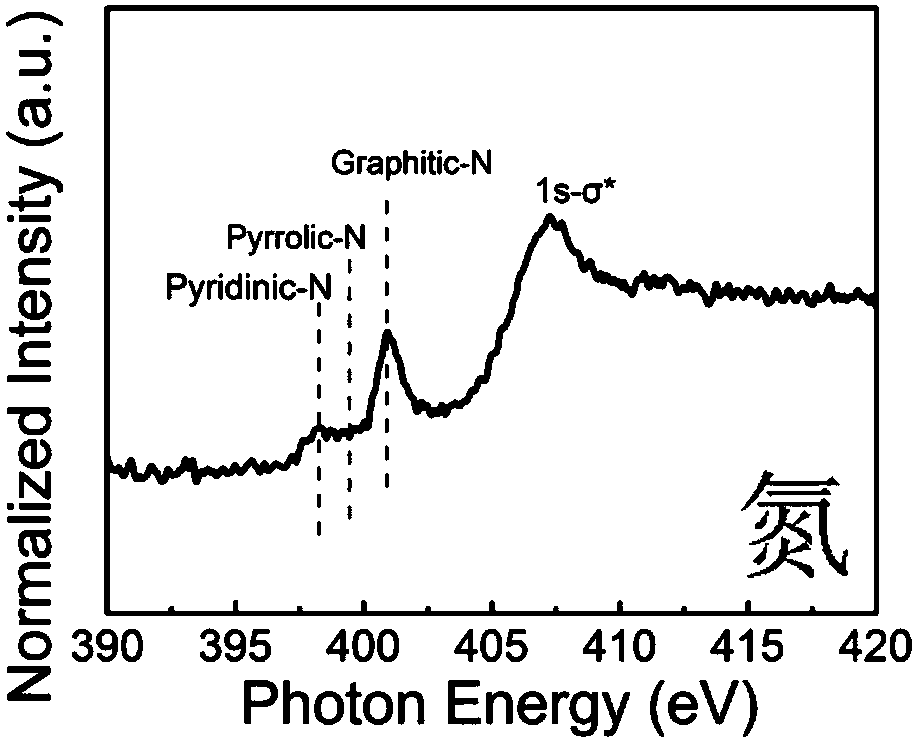

[0028] 5) The obtained nitrogen / sulfur co-doped porous carbon airgel is subjected to high-temperature heat treatment (1000°C, 1 hour) to remove a part of nitrogen and sulfur heteroatoms to obtain a nitrogen / sulfur co-doped porous carbon gas with a defect structure gel;

[0029] 6) Use an electroch...

Embodiment 2

[0031] 1) Configure 200mL of iota-type carrageenan aqueous solution with a mass fraction of 2%, add 4g of urea, cool down after stirring, and obtain a carrageenan-urea hydrogel.

[0032] 2) preparing carrageenan-urea hydrogel into carrageenan-urea aerogel by freeze-drying;

[0033] 3) Carrageenan-urea airgel was calcined at 700°C for 1 hour in a tube furnace under an argon atmosphere to obtain nitrogen / sulfur co-doped carbon airgel;

[0034] 4) Remove calcium sulfide, sodium sulfide and other nanoparticles in the nitrogen / sulfur co-doped carbon aerogel with an aqueous hydrochloric acid solution with a concentration of 2M to obtain a nitrogen / sulfur co-doped porous carbon aerogel;

[0035] 5) The obtained nitrogen / sulfur co-doped porous carbon airgel is subjected to high-temperature heat treatment (1100°C, 1 hour) to remove a part of nitrogen and sulfur heteroatoms to obtain a nitrogen / sulfur co-doped porous carbon gas with a defect structure gel;

[0036] 6) Use an electroch...

Embodiment 3

[0038] 1) Configure 200mL of iota-type carrageenan aqueous solution with a mass fraction of 2%, add 4g of urea, cool down after stirring, and obtain a carrageenan-urea hydrogel.

[0039] 2) preparing carrageenan-urea hydrogel into carrageenan-urea aerogel by freeze-drying;

[0040] 3) Carrageenan-urea airgel is calcined at 600, 800, 900, and 1000°C for 1 hour in a tube furnace under an argon atmosphere to obtain nitrogen / sulfur co-doped carbon airgel;

[0041] 4) Remove calcium sulfide, sodium sulfide and other nanoparticles in the nitrogen / sulfur co-doped carbon aerogel with an aqueous hydrochloric acid solution with a concentration of 2M to obtain a nitrogen / sulfur co-doped porous carbon aerogel;

[0042] 5) The obtained nitrogen / sulfur co-doped porous carbon airgel is subjected to high-temperature heat treatment (1000°C, 1 hour) to remove a part of nitrogen and sulfur heteroatoms to obtain a nitrogen / sulfur co-doped porous carbon gas with a defect structure gel;

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com