Metal organic framework reverse osmosis membrane and preparation method thereof

A technology of metal-organic framework and reverse osmosis membrane, which is applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of high system energy consumption, low flux, and high energy consumption of seawater membrane method, and achieve operational Simple, low manufacturing cost, and the effect of improving throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

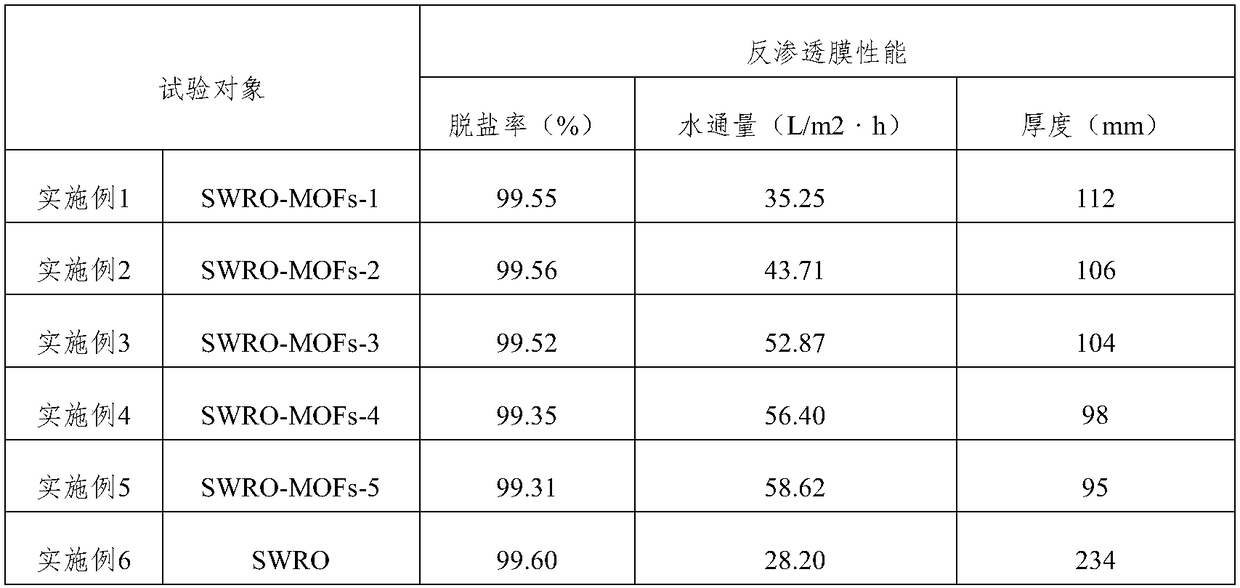

Examples

Embodiment 1

[0034] A method for preparing a metal-organic framework reverse osmosis membrane, comprising the following steps:

[0035] (1) Preparation of metal-organic frameworks: Silver nitrate and N,N-dimethylformamide (DMF) were ultrasonically dispersed for 10 min at a mass ratio of 1:38, trimesic acid and N,N-dimethylformamide Amide (DMF) was ultrasonically dispersed for 10 minutes according to the mass ratio of 1:38, the two were mixed and ultrasonicated for 1 hour, centrifuged and filtered, and the obtained solid was washed 3 times with a mixture of water and ethanol (V water: V ethanol = 1:1), After drying at 60 °C for 24 h, the obtained metal organic framework nanomaterials were kept in a vacuum desiccator until use.

[0036] (2) Preparation of the support layer: mix and disperse 0.15wt% polyvinylpyrrolidone and N,N-dimethylformamide (DMF), and stir at a stirring speed of 60r / min, so that the polyvinylpyrrolidone is Disperse evenly in N,N-dimethylformamide (DMF) solution, maintai...

Embodiment 2

[0041] A method for preparing a metal-organic framework reverse osmosis membrane, comprising the following steps:

[0042] (1) Preparation of metal-organic frameworks: Silver nitrate and N,N-dimethylformamide (DMF) were ultrasonically dispersed for 10 min at a mass ratio of 1:38, trimesic acid and N,N-dimethylformamide Amide (DMF) was ultrasonically dispersed for 10 minutes according to the mass ratio of 1:38, the two were mixed and ultrasonicated for 1 hour, centrifuged and filtered, and the obtained solid was washed 4 times with a mixture of water and ethanol (V water: V ethanol = 1:1), After drying at 60 °C for 24 h, the obtained metal organic framework nanomaterials were kept in a vacuum desiccator until use.

[0043] (2) Preparation of support layer: 1wt% polyvinylpyrrolidone and N, N-dimethylformamide (DMF) are mixed and dispersed, and the stirring speed is 70r / min for stirring treatment, so that polyvinylpyrrolidone is in N , Disperse evenly in the N-dimethylformamide ...

Embodiment 3

[0048] A method for preparing a metal-organic framework reverse osmosis membrane, comprising the following steps:

[0049] (1) Preparation of metal-organic frameworks: Silver nitrate and N,N-dimethylformamide (DMF) were ultrasonically dispersed for 10 min at a mass ratio of 1:38, trimesic acid and N,N-dimethylformamide Amide (DMF) was ultrasonically dispersed for 10 minutes according to the mass ratio of 1:38, the two were mixed and ultrasonicated for 1 hour, centrifuged and filtered, and the obtained solid was washed 4 times with a mixture of water and ethanol (V water: V ethanol = 1:1), After drying at 60 °C for 24 h, the obtained metal organic framework nanomaterials were kept in a vacuum desiccator until use.

[0050] (2) Preparation of support layer: mix and disperse 2.5wt% polyvinylpyrrolidone and N,N-dimethylformamide (DMF), and stir at a stirring speed of 75r / min, so that polyvinylpyrrolidone Disperse evenly in the N,N-dimethylformamide (DMF) solution, maintain the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com