A kind of preparation method of biomass hierarchical porous carbon material

A technology of graded porous and biomass raw materials, applied in the field of porous carbon materials, can solve the problems of limited sources, high cost, and few varieties, and achieve the effects of enhanced compatibility, good performance, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The steps for preparing biomass porous carbon nanomaterials in this embodiment:

[0052] 1) Pyrolysis: Pyrolysis and carbonization of 30 g of dried and crushed corn cob particles in a nitrogen protective atmosphere, grinding the carbonized material, and passing through a 50-mesh sieve to obtain a carbon-containing solid powder; The decarburization conditions were as follows: at a nitrogen flow rate of 150 mL / min, the temperature was raised from 25 °C to 500 °C at a rate of 5 °C / min, and kept at 500 °C for 1 h.

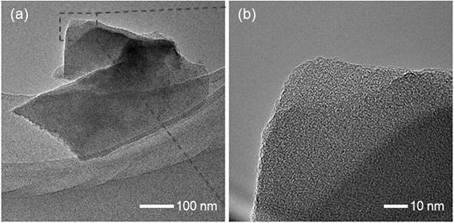

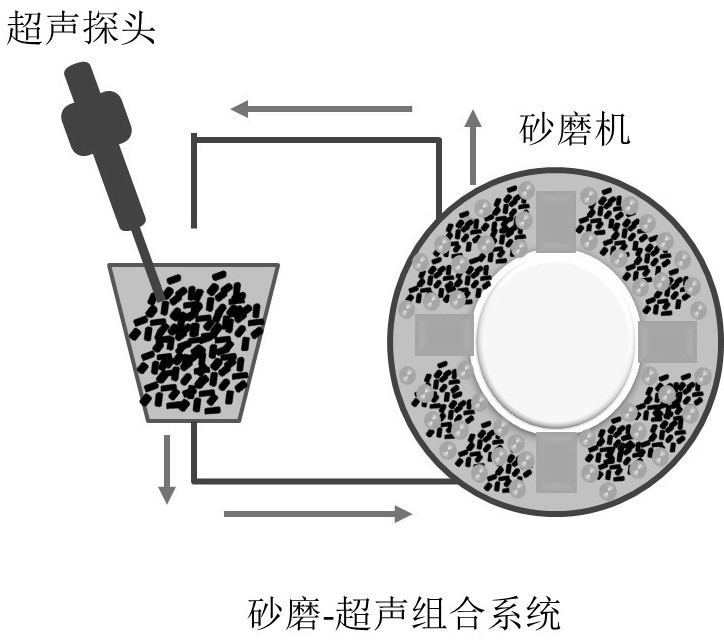

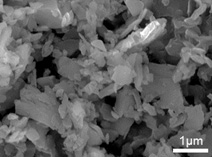

[0053] 2) Ultrafine treatment: Disperse 15g of carbon-containing solid powder in step 1) in 300mL of isopropanol aqueous solution (the volume ratio of isopropanol to deionized water is 3:7), and then ultrasonically and sand mill together Under the effect of superfine treatment, to obtain a suspension, the suspension is centrifuged at 10000 rpm, collected and dried to obtain an ultrafine carbon powder; in the present embodiment, the treatment time of the superfin...

Embodiment 2

[0062] The steps for preparing biomass porous carbon nanomaterials in this embodiment:

[0063] 1) Pyrolysis: Pyrolysis and carbonization of 30 g of dried and crushed corn cob particles in a nitrogen protective atmosphere, grinding the carbonized material, and passing through a 50-mesh sieve to obtain a carbon-containing solid powder; The decarburization conditions were as follows: at a nitrogen flow rate of 150 mL / min, the temperature was raised from 25 °C to 500 °C at a rate of 5 °C / min, and kept at 500 °C for 1 h.

[0064] 2) Ultrafine treatment: Disperse 15g of carbon-containing solid powder in step 1) in 300mL of isopropanol aqueous solution (the volume ratio of isopropanol to deionized water is 3:7), and then ultrasonically and sand mill together Under the effect of superfine treatment, to obtain a suspension, the suspension is centrifuged at 10000 rpm, collected and dried to obtain an ultrafine carbon powder; in the present embodiment, the treatment time of the superfin...

Embodiment 3

[0070] The steps for preparing biomass porous carbon nanomaterials in this embodiment:

[0071] 1) Pyrolysis: Pyrolysis and carbonization of 30 g of dry and crushed straw particles in a nitrogen protective atmosphere, grinding the carbonized material, and passing through a 50-mesh sieve to obtain a carbon-containing solid powder; the pyrolysis described in this example The carbonization conditions were as follows: at a nitrogen flow rate of 150 mL / min, the temperature was raised from 25 °C to 400 °C at a rate of 3 °C / min, and kept at 400 °C for 1 h.

[0072] 2) Ultrafine treatment: Disperse 15g of carbon-containing solid powder in step 1) in 300mL of water, then perform ultrafine treatment under the combined action of ultrasound and sand mill to obtain a suspension, and centrifuge the suspension at 10,000 rpm , collected and dried to obtain ultra-fine carbon powder; in this embodiment, the treatment time of ultra-fine treatment is 10h; the power of the ultrasonic wave is 100W;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com