A method for preparing slag-free pac by using high-efficiency emulsification shear stirring technology

A technology of emulsification shearing and technology, applied in chemical instruments and methods, aluminum halide, aluminum chloride, etc., can solve the problems of large amount of secondary hazardous waste sludge, increased production costs of enterprises, and increased outsourcing disposal costs, etc. , to achieve the effects of ensuring sustainable development, low equipment investment costs, high-tech content and innovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

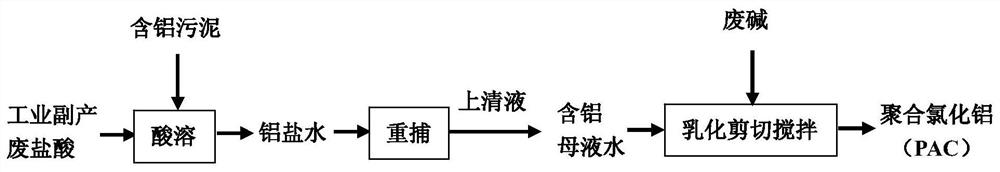

Method used

Image

Examples

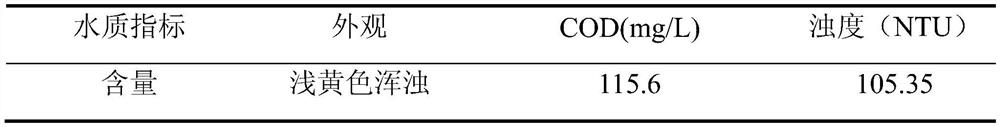

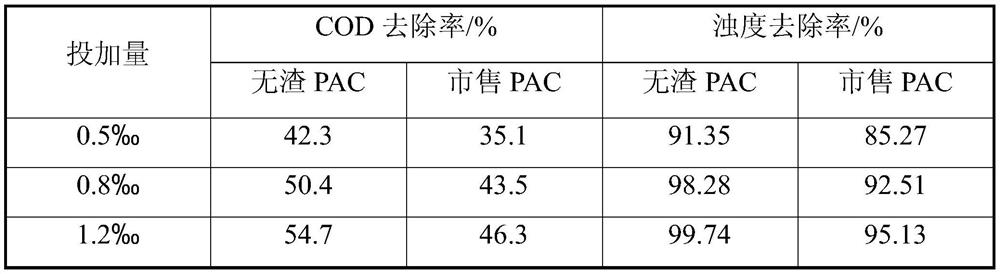

Embodiment 1

[0026] Combine 300g of industrial by-product waste hydrochloric acid (HCl mass fraction is 12.75%) and 100g of aluminum-containing sludge from the aluminum profile industry (Al 2 o 3 The mass fraction is 16.35%) to carry out acid-dissolution reaction, stirring and reacting at normal temperature and pressure for 1h until the aluminum-containing sludge is completely dissolved to obtain Al 2 o 3 Aluminum brine with a mass fraction of 4.09% and a HCl mass fraction of 0.79%; add 0.2g of TMT liquid heavy metal scavenger, stir and react for 0.5h, and let it settle for 2h to obtain a light yellow supernatant containing aluminum mother liquor water; take the supernatant 325g of liquid aluminum-containing mother liquor water was placed in an emulsification shear mixer for high-speed emulsification shear stirring, and at the same time slowly added 84g of liquid waste alkali (Al 2 o 3 The mass fraction is 18.62%, and the NaOH mass fraction is 24.47%) to adjust the degree of polymerizat...

Embodiment 2

[0028] Combine 300g of industrial by-product waste hydrochloric acid (HCl mass fraction is 26.63%) and 100g of aluminum-containing sludge from the aluminum profile industry (Al 2 o 3 The mass fraction is 27.73%) to carry out the acid-dissolution reaction, stirring and reacting at normal temperature and pressure for 1.5h until the aluminum-containing sludge is completely dissolved to obtain Al 2 o 3 Aluminum brine with a mass fraction of 6.93% and a HCl mass fraction of 5.09%; add 0.4g of TMT liquid heavy metal scavenger, stir and react for 1 hour, and let it settle for 2.5 hours to obtain a light yellow supernatant liquid containing aluminum mother liquor; take the supernatant 327g of liquid aluminum-containing mother liquor was placed in an emulsification shear mixer for high-speed emulsification shear stirring, and at the same time slowly added 120g of liquid waste alkali (Al 2 o 3 The mass fraction is 18.62%, and the NaOH mass fraction is 24.47%) to adjust the degree of ...

Embodiment 3

[0030] 300g of industrial by-product waste hydrochloric acid (HCl mass fraction is 23.88%) and 100g of aluminum-containing sludge from the aluminum profile industry (Al 2 o 3 The mass fraction is 26.31%) to carry out the acid-dissolution reaction, stirring and reacting at normal temperature and pressure for 2 hours until the aluminum-containing sludge is completely dissolved to obtain Al 2 o 3 Aluminum brine with a mass fraction of 6.58% and a HCl mass fraction of 3.79%; add 0.8g of TMT liquid heavy metal scavenger, stir and react for 1 hour, and let it settle for 3 hours to obtain a light yellow supernatant liquid containing aluminum mother liquor; take the supernatant 299g of aluminum-containing mother liquor water is placed in an emulsifying shear mixer for high-speed emulsifying shear stirring, and at the same time slowly add 120g of liquid waste alkali (Al 2 o 3 The mass fraction is 18.62%, and the NaOH mass fraction is 24.47%) to adjust the degree of polymerization of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com