An anaerobic baffle reaction device and sewage treatment method

An anaerobic baffle and reaction device technology, which is applied in the field of anaerobic baffle reaction devices and sewage treatment, can solve the problems of high energy consumption and high operating costs, and achieve low energy consumption, improved uniform distribution, and good push flow Fluid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

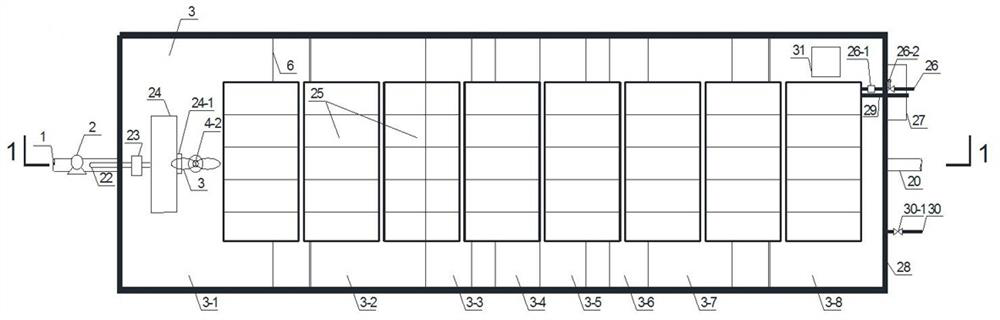

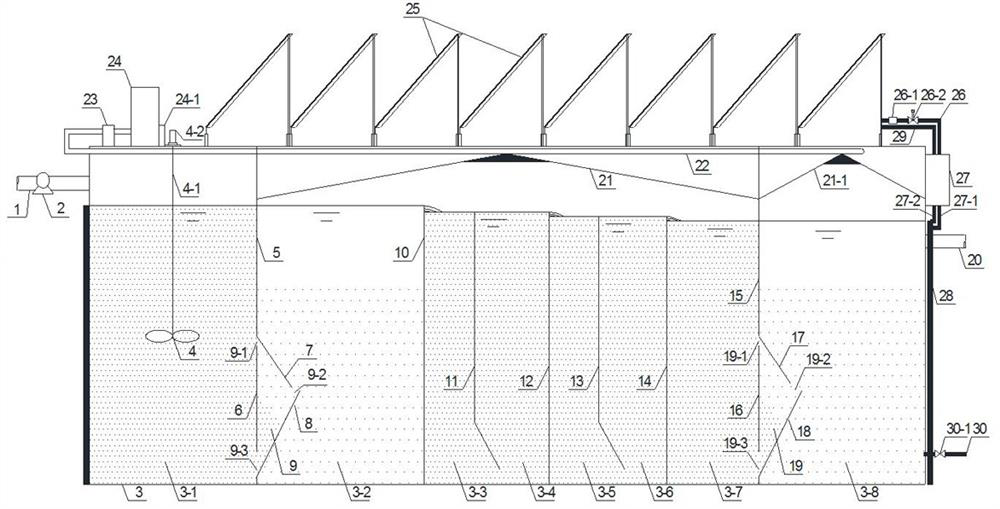

[0021] Such as figure 1 and 2 Shown, a kind of anaerobic baffle reaction device, comprises reaction pool 3, is positioned at in reaction pool 3 and is separated by dividing plate and baffle to form a plurality of hydrolysis fermentation areas and methanogenic area, hydrolysis fermentation area and methanogenic area Connected in series and allow sewage to flow through one by one, the hydrolysis fermentation zone at the front and the methanogenic zone at the rear are connected to the water inlet pipe 1 and the water outlet pipe 20 respectively, and the water inlet pipe 1 is provided with an inlet pump 2 .

[0022] The anaerobic baffle reaction device described in this embodiment also includes a chemical energy power generation system and a solar heating system. The chemical energy power generation system includes a biogas collector 21 (21-1), a biogas collection pipe 22, a biogas preprocessor 23 and a biogas The generator 24, the biogas collector 21 (21-1) is covered above the ...

Embodiment 2

[0036] This embodiment discloses a method for sewage treatment using the solar heat preservation / chemical energy described in Example 1 to drive the anaerobic folded plate flow reaction device, including the following steps:

[0037] 1. Operation of the reaction pool:

[0038] The incoming water (sewage) enters the reaction tank 3 through the water inlet pipe 2 under the suction of the water inlet pump 1. Under the normal working condition of the agitator 4, the pollutants in the sewage flow up and down along the baffle plate in the reaction tank with the water flow. , in the independent hydrolysis fermentation area and methane production area, it is degraded and metabolized by anaerobic activated sludge, so that the water quality is purified. The MLSS of the anaerobic activated sludge in the reaction tank 3 is 8000mg / L-15000mg / L, and the hydraulic retention time is 12-24h. The purified sewage is discharged through the outlet pipe 20 .

[0039] Second, the power of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com