Processing method of waste plastic

A treatment method and technology of waste plastics, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of complex product distribution, high reaction temperature, etc., and achieve the effects of simple process flow, lower reaction temperature, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

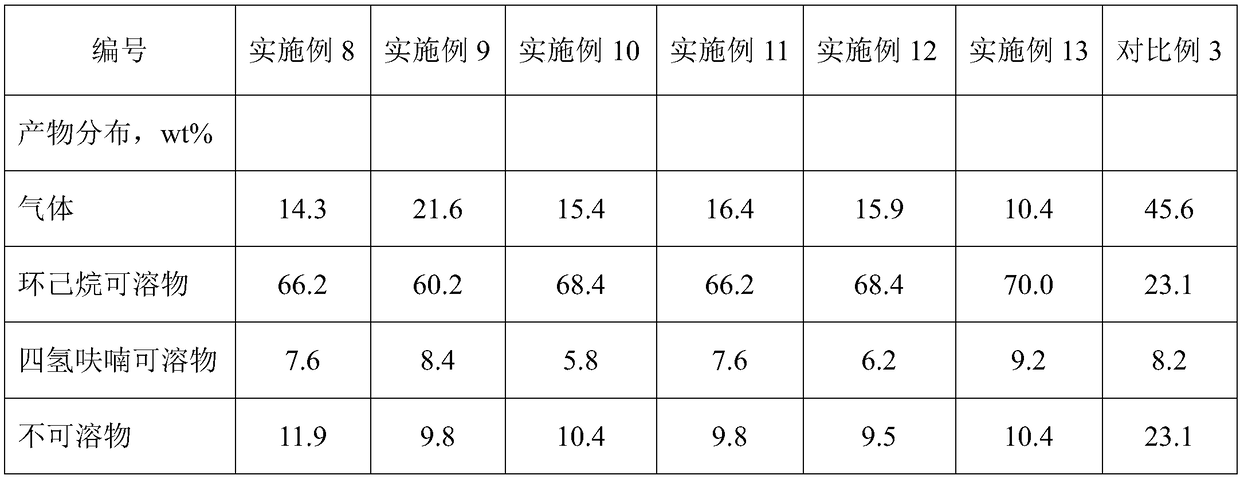

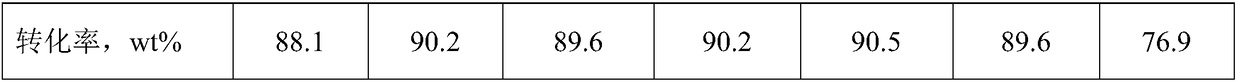

Examples

preparation example Construction

[0023] The preparation method of modified catalyst A used in the embodiment is: take 1g of HZSM-5 and HY molecular sieve respectively and mix, then add concentration and be that in the sodium hydroxide aqueous solution of 0.2mol / L, carry out partial desiliconization treatment, treatment temperature is 60°C for 1 hour, then filter, wash, and dry at 100°C for 12 hours; weigh 0.2g of tin chloride and 0.015g of sodium silicate plus deionized water to make an aqueous solution, and then dip into The above-mentioned composite molecular sieves were dried at 100°C for 12 hours, and then calcined at 450°C for 3 hours to obtain the modified catalyst A powder, which was pressed into tablets and sieved to obtain solid particles with a particle size of 40 mesh to 60 mesh. The particles were used as modified catalyst A.

[0024] The preparation method of modified catalyst B used in the embodiment is: change the tin chloride of 0.2g in the preparation method of modified catalyst A into the ti...

Embodiment 1

[0028] Get 2g polyethylene terephthalate plastics (PET) and join in the catalytic cracking reactor as the waste plastic raw material of reaction, and add modified catalyst A and reaction solvent, reaction solvent is 30wt% tetralin and 70wt% n-hexadecane A mixture of alkanes, wherein the amount of modified catalyst A added is 10% of the waste plastic mass, and the amount of reaction solvent is 2g. After mixing evenly, the reaction is carried out under the following reaction conditions: the reaction temperature is 250 ° C, and the reaction time is 180 minutes. The reaction was carried out under stirring with a stirring rate of 700 rpm, hydrogen gas was introduced into the reaction, and the hydrogen partial pressure was 5.6 MPa. The obtained cleavage product is separated by gas-liquid-solid to obtain liquid phase product, gas and insoluble matter; and then the obtained liquid phase product is extracted through cyclohexane and tetrahydrofuran respectively to obtain cyclohexane solu...

Embodiment 2

[0029] Change modified catalyst A in embodiment 1 into modified catalyst B, and others are the same as embodiment 1. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com