Preparation method of vulcanizing activator taking metal organic framework material as carrier

A metal-organic framework and vulcanization activator technology, which is applied in the field of vulcanization activators, can solve the problems of unfavorable product life and energy consumption, great impact on rubber density, and high specificity of zinc oxide, so as to achieve good coordination and improve vulcanization Efficiency, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

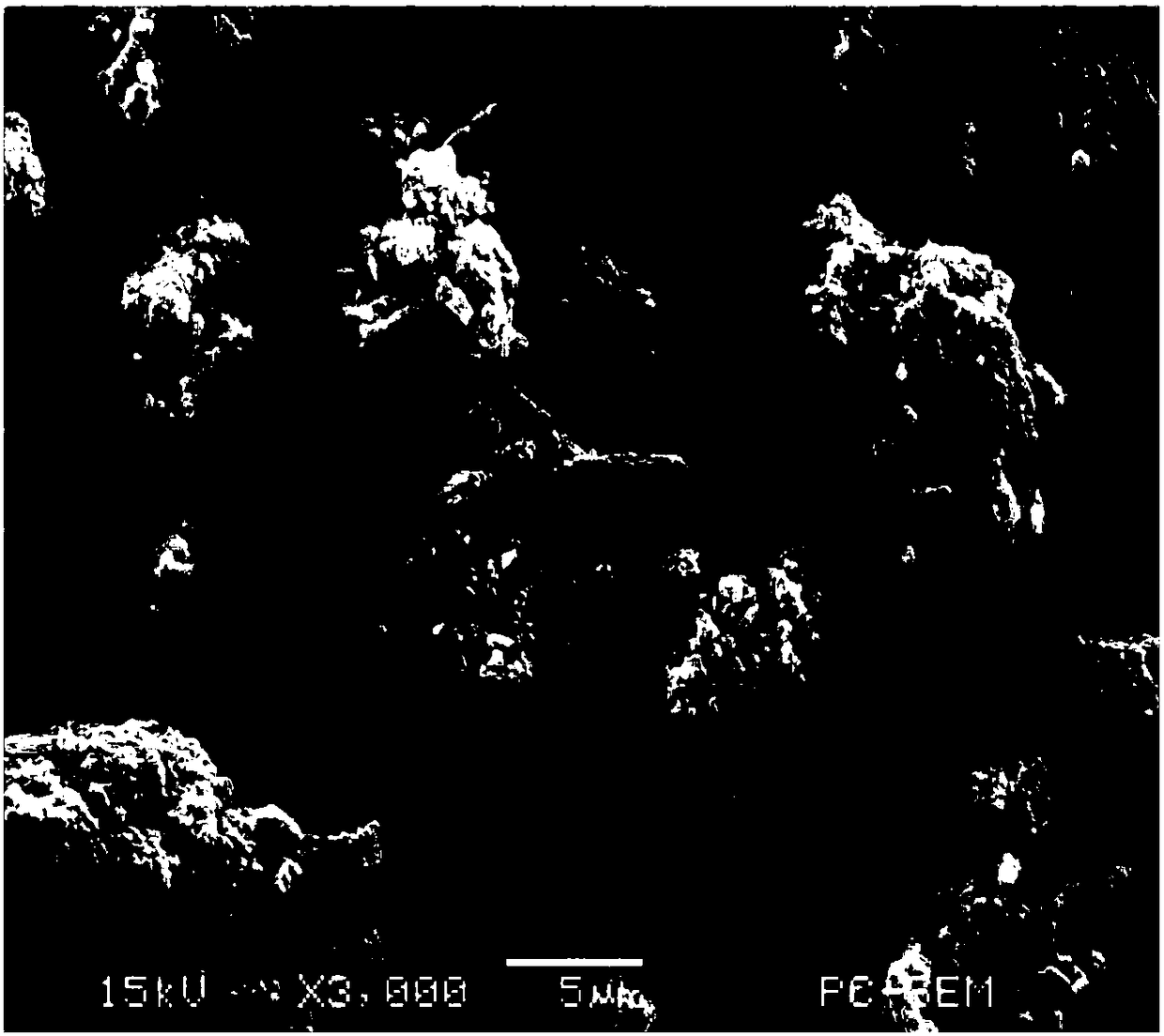

Image

Examples

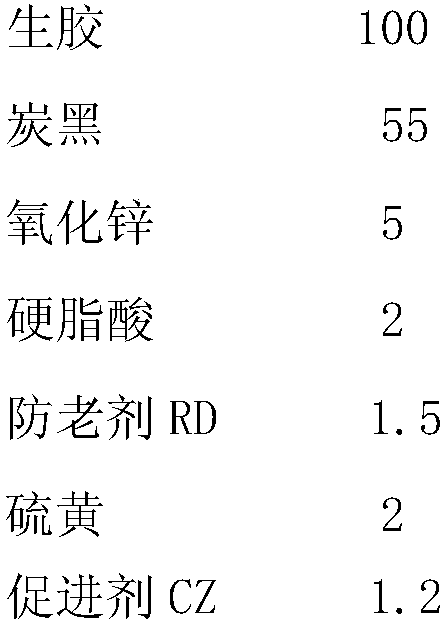

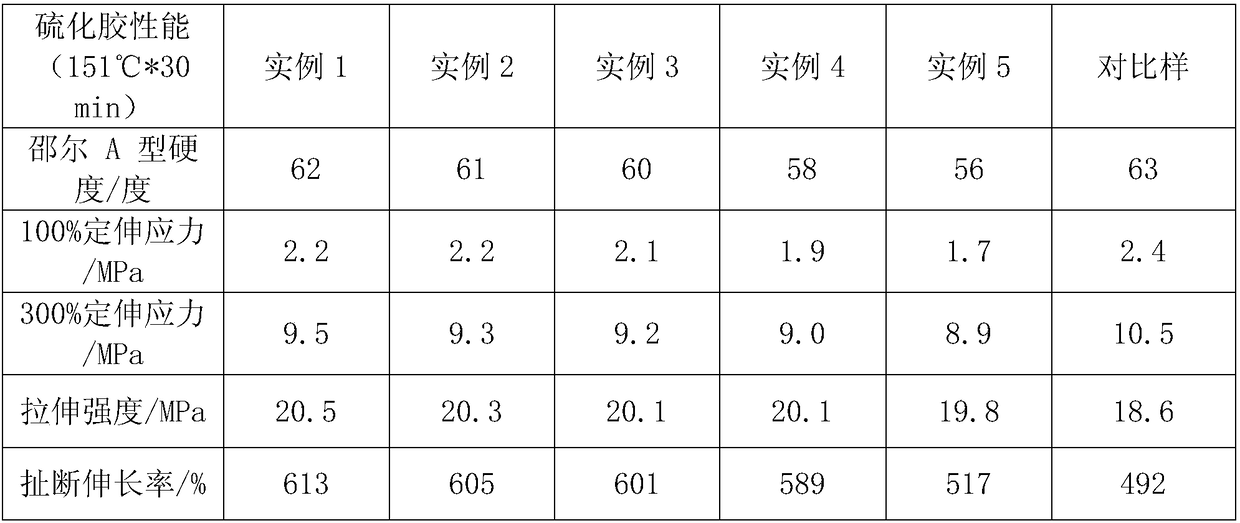

Embodiment 1

[0031] A method for preparing a vulcanization activator with a metal-organic framework material as a carrier, comprising the steps of:

[0032] S1 Preparation of metal-organic framework material precursor: 21.0 grams of trimesic acid was dissolved in 150 grams of water, stirred evenly, and 40 grams of 30% sodium hydroxide solution was slowly added, wherein the molar ratio of sodium hydroxide to trimesic acid was 3: 1. Trimellitic acid is reacted with sodium hydroxide, and the pH is controlled to be less than 13 during the addition process until the trimesic acid is completely dissolved, and left to stand for a period of time to form a transparent sodium trimesate solution;

[0033] S2 preparation of zinc metal organic framework material: dissolve 20.4 grams of zinc chloride in 100 grams of water, and add the sodium trimesate solution prepared in the above S1 under the condition of stirring at a molar ratio of 1.5:1 to generate tribenzene Zinc triformate precipitation;

[0034...

Embodiment 2

[0038] A method for preparing a vulcanization activator with a metal-organic framework material as a carrier, comprising the steps of:

[0039] S1 Preparation of metal-organic framework material precursor: 25.0 grams of pyromellitic acid was dissolved in 150 grams of water, stirred evenly, and 53.3 grams of 30% sodium hydroxide solution was slowly added, wherein the molar ratio of sodium hydroxide to pyromellitic acid was 4: 1. React pyromellitic acid with sodium hydroxide. During the addition process, control the pH to be less than 13 until the pyromellitic acid is completely dissolved, and let stand for a period of time to form a transparent sodium pyromellitic acid solution;

[0040] S2 preparation of zinc metal organic framework material: dissolve 27.3 grams of zinc chloride in 100 grams, and add it to the sodium pyromellitic acid solution prepared in the above S1 under the condition of stirring at a molar ratio of 2:1 to generate pyromellitic acid Zinc tetracarboxylate pr...

Embodiment 3

[0045] A method for preparing a vulcanization activator with a metal-organic framework material as a carrier, comprising the steps of:

[0046] S1 Preparation of metal-organic framework material precursor: 16.6 grams of terephthalic acid was dissolved in 150 grams of water, stirred evenly, and 26.7 grams of 30% sodium hydroxide solution was slowly added, wherein the molar ratio of sodium hydroxide to terephthalic acid was 2: 1. Terephthalic acid reacts with sodium hydroxide. During the addition of sodium hydroxide, the pH is controlled to be less than 13 until the terephthalic acid is completely dissolved and allowed to stand for a period of time to form a transparent sodium terephthalate solution;

[0047] S2 preparation of zinc metal organic framework material: dissolve 13.6 grams of zinc chloride in 100 grams of water, add the sodium terephthalate solution prepared in the above S1 under the condition of stirring at a molar ratio of 1:1, and generate terephthalic acid Zinc f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com