Staining method for blended yarn weaved fabric

A technology of blended fabrics and dyeing methods, which is applied in the direction of dyeing methods, textile material processing, and equipment configuration for processing textile materials. It can solve the problems of poor dyeing effect and inability to guarantee the color consistency of fabrics, so as to avoid precipitation and ensure consistency. , Dyeing reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

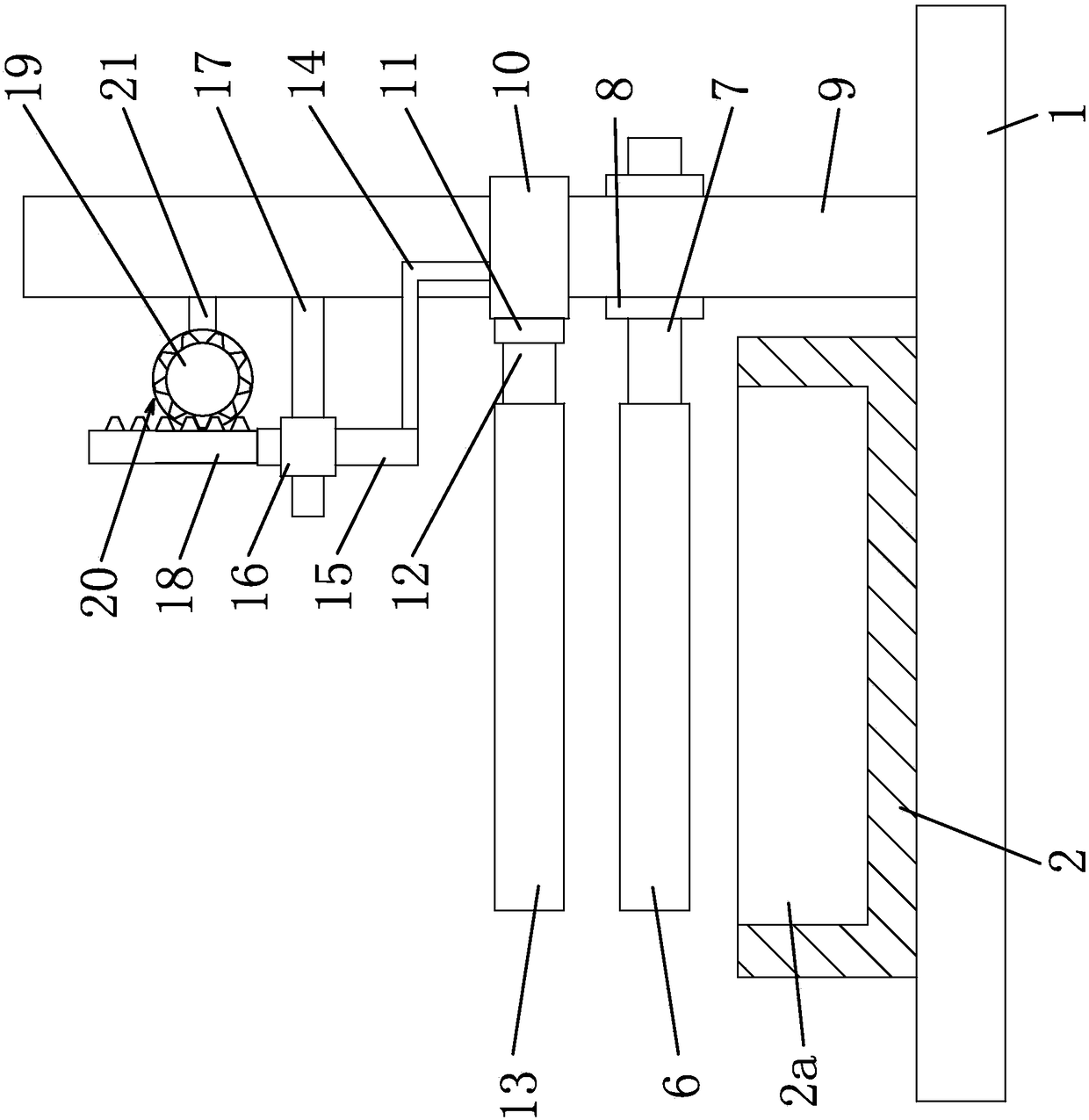

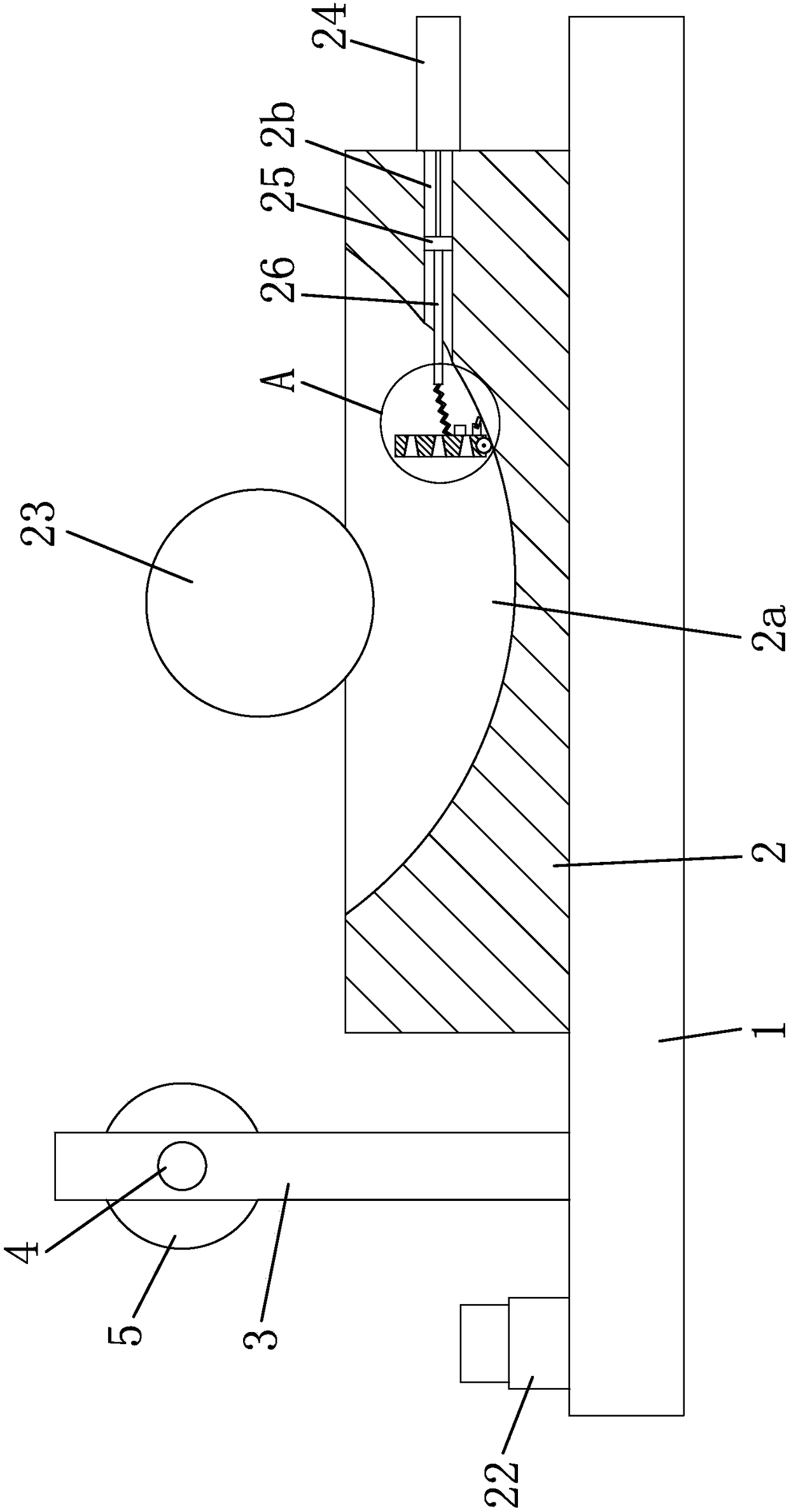

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0040] The dyeing method of this blended fabric comprises the steps:

[0041] a. Weaving: weaving four raw materials of flax fiber, activated carbon fiber, viscose filament fiber and polyester fiber into blended fabric;

[0042] b. Ingredients: by weight, 6-12 parts of natural plant pigments, 1-3 parts of calcium sulfate, 1-3 parts of magnesium sulfate, 0.4-0.8 parts of aluminum oxide powder, 2-5 parts of alcohol and 40 parts of water -50 parts are put into the blender together, stir evenly, make dye liquor; 4 parts and 45 parts of water are put into the blender together, stir evenly, make dye liquor; Natural vegetable pigment adopts the existing product that can buy on the market;

[0043] c, dyeing: put the dye solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com