Method for liquid phase catalytic hydrogenation deiodination of iodination X-ray contrast medium

A liquid-phase catalysis and X-ray technology, applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of irreversible leaching, easy agglomeration, catalyst deactivation, etc., and achieve easy degradation, no secondary pollution, and degradation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A mesoporous carbon nitride-supported noble metal catalyst was prepared, which included Pd-supported mesoporous carbon nitride Pd / MCN. As a comparison, a mesoporous carbon-supported catalyst Pd / CMK-3 was also prepared. The specific method includes the following steps:

[0038] (1) Synthesis of SBA-15: SBA-15 was synthesized using triblock copolymer P123 as surfactant and tetraethyl orthosilicate (TEOS) as silicon source. Dissolve 4g P123 in 126ml 2mol / l hydrochloric acid, dissolve in a water bath at 40°C, add 20.8gTEOS completely, stir for 24h, then transfer the solution to an autoclave for aging at 80°C for 48h, filter, wash and dry, place in a muffle furnace at 1°C / min to 550°C for 6 hours to remove the P123 organic template.

[0039](2) Synthesis of CMK-3: CMK-3 was synthesized using SBA-15 as a template and sucrose as a carbon source. Dissolve 5g of sucrose in 20ml of deionized water, add 0.56g of concentrated sulfuric acid and 4g of SBA-15, mix well, heat in an ...

Embodiment 2

[0043] The mesoporous carbon nitride supported noble metal catalyst was prepared and characterized according to the method of Example 1.

[0044] Mesoporous carbon nitride (MCN-500) or CMK-3 with a carbonization temperature of 500 °C and Pd salt precursor PdCl 2 Mixing and stirring, and loading by precipitation deposition method to obtain supported Pd / MCN-500 or Pd / CMK-3, wherein the loaded amount of Pd is 2%wt.

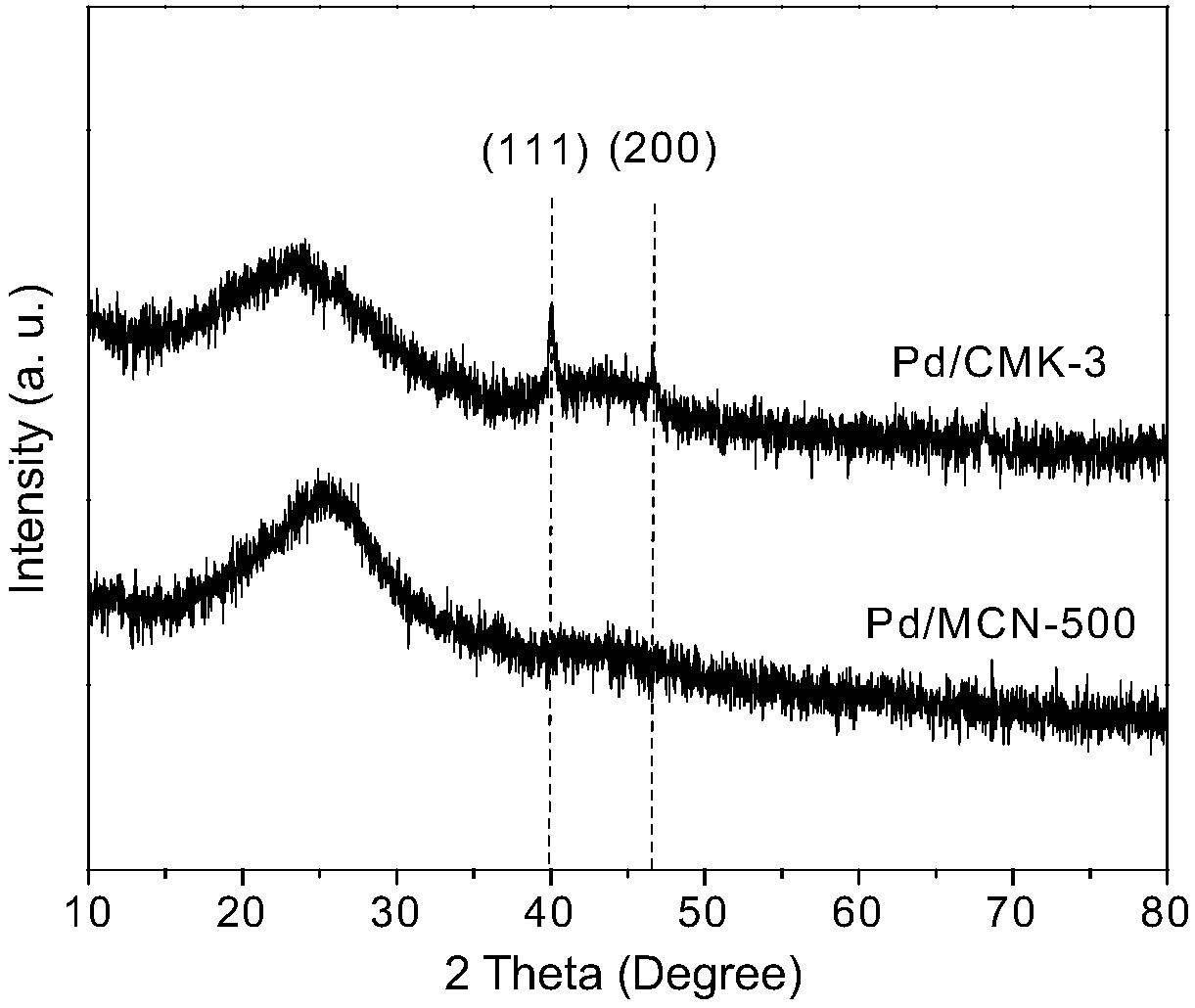

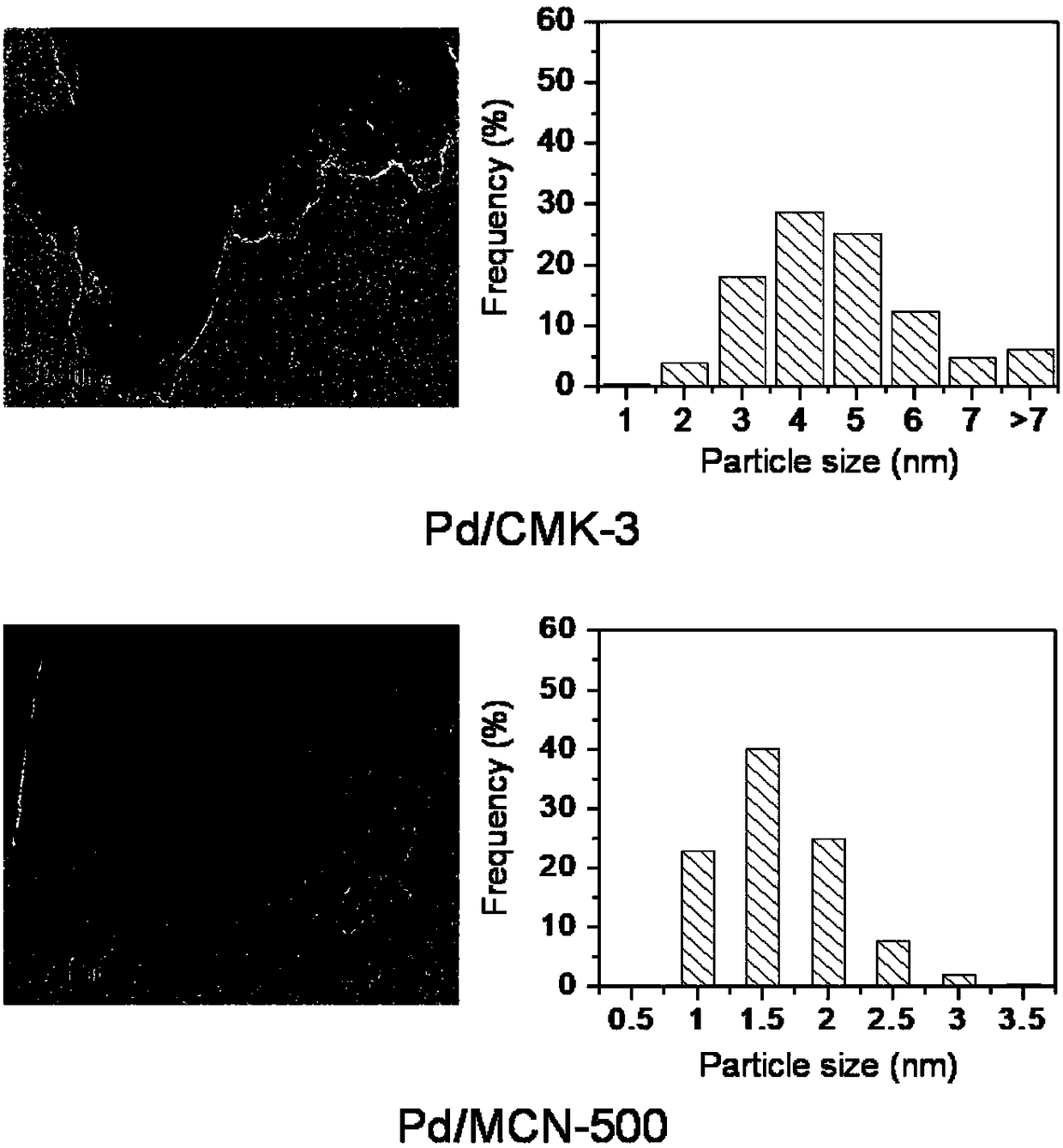

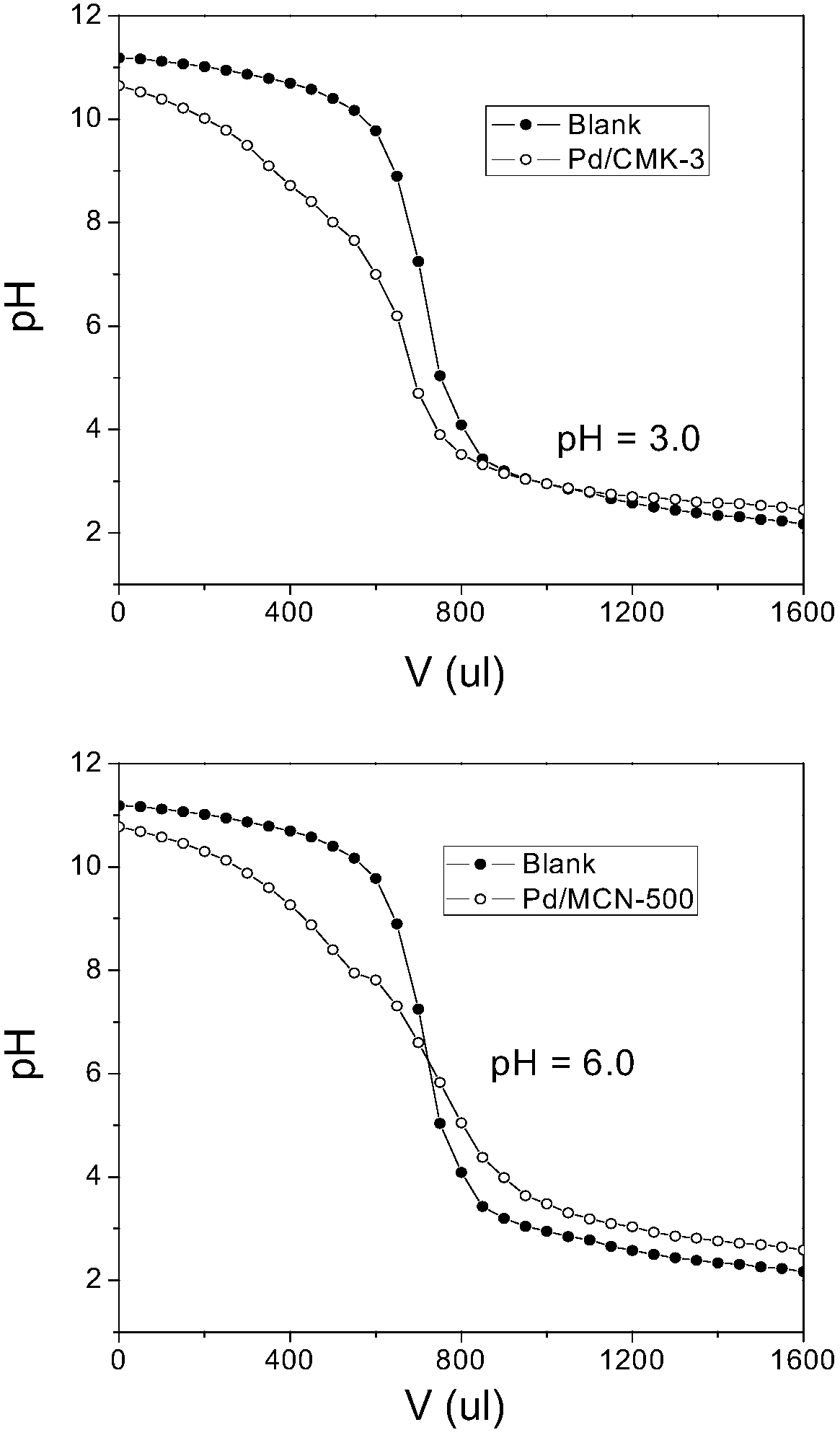

[0045] (1) Wide-angle XRD of Pd / CMK-3 and Pd / MCN-500 such as figure 1 As shown, in the wide-angle XRD pattern of Pd / CMK-3, weak diffraction peaks representing the (111) plane and (200) plane of Pd appear at 39.4° and 45.8° respectively, indicating that the noble metal Pd was successfully loaded on the CMK-3 carrier superior. Compared with the XRD pattern of Pd / CMK-3, the corresponding Pd diffraction peaks in the XRD pattern of Pd / MCN-500 are weaker, indicating that the distribution of noble metal Pd on the MCN-500 carrier is more uniform than that of CMK-3.

[004...

Embodiment 3

[0049] The above-prepared Pd / MCN was used as a catalyst to carry out liquid-phase catalytic hydrodeiodination reaction of DTZ and IOP in water. The specific reaction process is as follows: Add an appropriate amount of sodium diatrizoate or iopamidol in a four-necked flask, mix well, add an appropriate amount of the catalyst prepared in Example 1, feed nitrogen and stir vigorously, after a period of equilibrium, nitrogen Switching to hydrogen, the ICM performs a liquid-phase catalytic hydrodeiodination reaction.

[0050] (1) The catalyst is Pd / MCN-500 with a concentration of 0.075g / l, the initial pH of the reaction is 7.0, the hydrogen flow rate is 200ml / min, and the reaction is carried out at normal temperature and pressure for 2 hours. The initial reaction concentration was 0.4 mmol / l for ionic DTZ and 0.7 mmol / l for non-ionic IOP. See Figure 4 : It can be seen from the figure that the Pd / MCN-500 catalyst can complete the hydrodeiodination reaction of DTZ within 70 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com