Preparation method of heat-resistant lithium battery diaphragm

A lithium battery separator, heat-resistant technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problems of poor heat resistance, weak bonding between the separator ceramic layer and the base film, and the ceramic layer falling off. Good heat resistance, anti-shrinkage, anti-shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

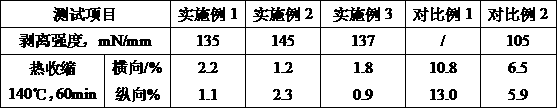

Embodiment 1

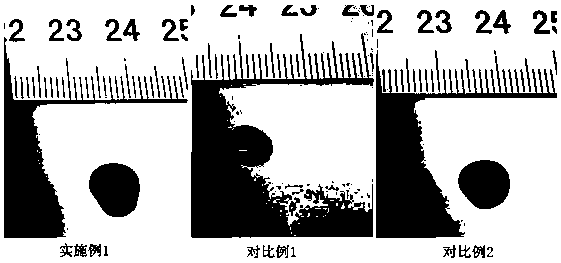

[0030] a. Preparation of water-based ceramic slurry: Add 40 parts of alumina and 0.1 part of sodium dodecylsulfonate to 50 parts of deionized water, and obtain a uniform solution after grinding for 1 hour, then add 0.1 part of suspension stabilizer, 0.1 Part of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.1 part of polyoxyethylene alkylamide, 0.1 part of sodium hydroxypropyl sulfonate methacrylate, 1 part of the first binder, 1 part of the second binder, low-speed dispersion for 30 minutes , to obtain water-based ceramic slurry;

[0031] b. Coating: apply the water-based ceramic slurry prepared in step a to one side of a 12 μm polyethylene monolayer film by gravure roll coating to obtain a water-based ceramic slurry coating, and then in a temperature of 70 ° C Bake for 1 min under the same conditions to obtain a heat-resistant lithium battery separator, in which the thickness of the ceramic coating is 4 μm.

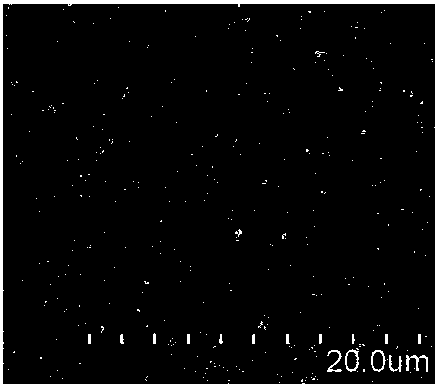

[0032] Among them, the average particle size of alumin...

Embodiment 2

[0036] a. Preparation of water-based ceramic slurry: Add 45 parts of alumina and 0.2 parts of sodium lauryl sulfate to 60 parts of deionized water, and obtain a uniform solution after grinding for 1 hour, then add 0.2 parts of suspension stabilizer, 0.3 parts of Polyoxyethylene polyoxypropanol amine ether, 0.2 part of fatty alcohol polyoxyethylene ether, 0.2 part of sodium hydroxypropyl sulfonate methacrylate, 2 parts of the first binder, 2 parts of the second binder, low-speed dispersion for 20 minutes , to obtain water-based ceramic slurry;

[0037] b. Coating: apply the water-based ceramic slurry prepared in step a on one side of the 12 μm polyethylene monolayer film by anilox roller coating to obtain a water-based ceramic slurry coating, and then apply the water-based ceramic slurry at a temperature of 60 ° C. Bake for 1 min under the condition of , to obtain a heat-resistant lithium battery separator, in which the thickness of the ceramic coating is 4 μm.

[0038] Among ...

Embodiment 3

[0042] a. Preparation of water-based ceramic slurry: Add 55 parts of boehmite and 0.2 parts of polyacrylic acid ammonium salt to 75 parts of deionized water, obtain a uniform solution after grinding for 1 hour, then add 0.2 parts of suspension stabilizer, 0.1 part of polyacrylate Oxyethylene polyoxypropylene pentaerythritol ether, 0.3 part of polyoxyethylene alkylamide, 0.5 part of sodium isethionate, 3 parts of the first binder, 2 parts of the second binder, dispersed at a low speed for 40 minutes to obtain a water-based ceramic slurry material;

[0043] b. Coating: apply the water-based ceramic slurry prepared in step a on one side of the 12 μm polyethylene monolayer film by anilox roller coating to obtain a water-based ceramic slurry coating, and then apply the water-based ceramic slurry at a temperature of 60 ° C. Bake for 1 min under the condition of , to obtain a heat-resistant lithium battery separator, in which the thickness of the ceramic coating is 4 μm.

[0044] Am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com