Preparation method of metal ammonium boron phosphate wood-plastic composite material capable of retarding flame and inhibiting smoke

A wood-plastic composite material and ammonium borophosphate technology, which is applied in the field of wood-plastic composite material manufacturing, can solve the problems of affecting the mechanical properties of wood-plastic materials, large amount of flame retardant added, low flame retardant and smoke suppression efficiency, etc., and achieves excellent performance. The effect of adsorption, reduction of flame retardant and smoke suppression performance, and high flame retardant and smoke suppression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

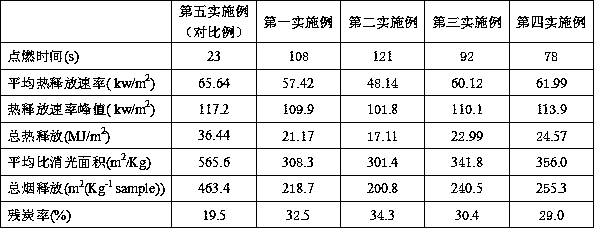

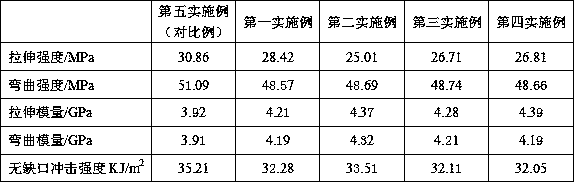

Examples

Embodiment 1

[0023] A method for preparing a metal ammonium borophosphate flame-retardant and smoke-suppressing wood-plastic composite material according to the present invention comprises the following steps:

[0024] Step 1, raw material preparation: weighing each raw material component by weight: thermoplastic, wood fiber, heat stabilizer, lubricant, coupling agent, metal ammonium borophosphate flame retardant and smoke suppressant;

[0025] Step 2, mixing materials: the wood fiber, thermoplastic resin and heat stabilizer weighed in step 1 are put into a high-speed mixer and mixed until the temperature is 85°C, and the mixing time is 5 minutes, then adding coupling agent and composite lubricant successively, Continue mixing for 8 minutes, then unload to low mixing, cool to a temperature of 40°C to obtain a mixture;

[0026] Step 3, granulation: melting and compounding the mixture obtained in step 2 with a twin-screw extruder to granulate, and then cooling by air cooling to obtain pellet...

Embodiment 2

[0036] A metal borophosphate ammonium salt fire-retardant and smoke-suppressing wood-plastic composite material consists of 100-300 parts of thermoplastic, 100-600 parts of wood fiber, 0-6 parts of heat stabilizer, 0.75-20 parts of Lubricant, 4.5-80 parts of coupling agent, 5-15 parts of metal borophosphate ammonium flame retardant and smoke suppressant are made by melt compounding, one-step molding or two-step molding processing.

Embodiment 3

[0038] The difference between this embodiment and the above-mentioned examples is that the particle size of the wood fiber is between 40-200 mesh, and the wood fiber is any one or a mixture of bamboo powder, crop straw powder, and fruit shell powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com