Carbon dioxide separation/recovery device, combustion system using same, thermal power generation system using same, and method for separating and recovering carbon dioxide

A carbon dioxide, separation and recovery technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as performance degradation of capture materials, and achieve the effect of inhibiting performance degradation and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

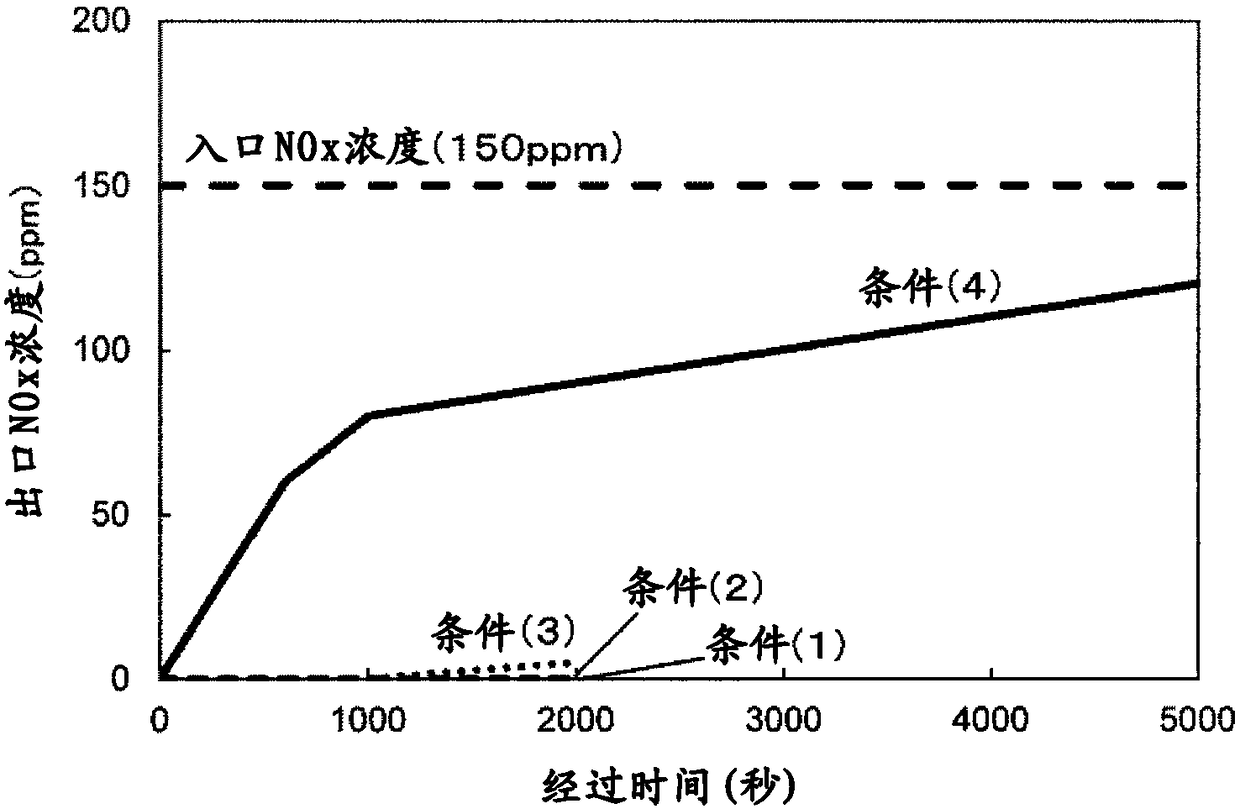

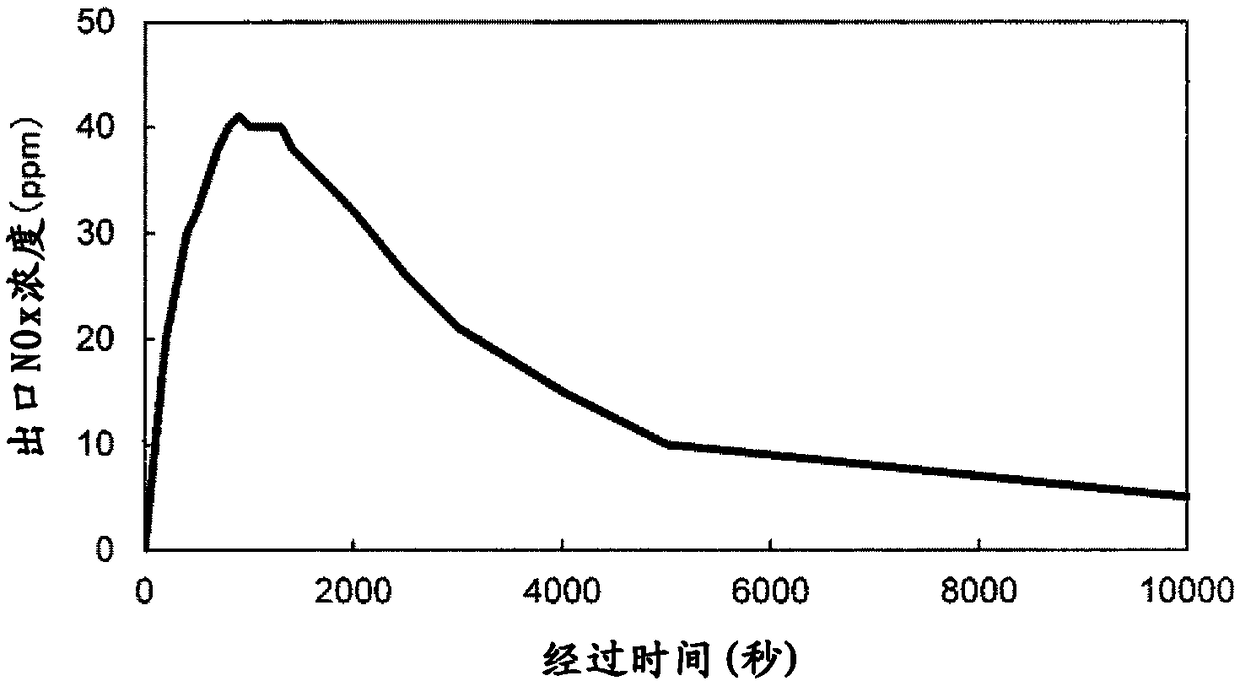

[0064] (NOx adsorption test)

[0065] Regarding the inclusion of H along with NOx 2 O and CO 2 The NOx adsorption characteristics in either or both of them were evaluated by the following method. as CO2 Capture material, high specific surface area CeO made of the first dilute element 2 .

[0066] About CO 2 The capture material is granulated by a press machine at 200kgf using a die with a diameter of 40mm, crushed, and then sized into 0.5-1.0mm granules using a sieve. Then, 20.0 ml was measured using a graduated cylinder, and it fixed in the reaction tube made of stainless steel. while using N 2 The gas was circulated at 2.0 L / min, and the temperature was raised to 200° C. using an electric furnace and held there for 1 hour to remove impurities and gas adsorbed on the capture material. Then, the CO 2 The temperature of the capture material was cooled to 50°C, and the outlet NOx concentration was measured under 4 conditions with different compositions of the flowing gas...

Embodiment 2

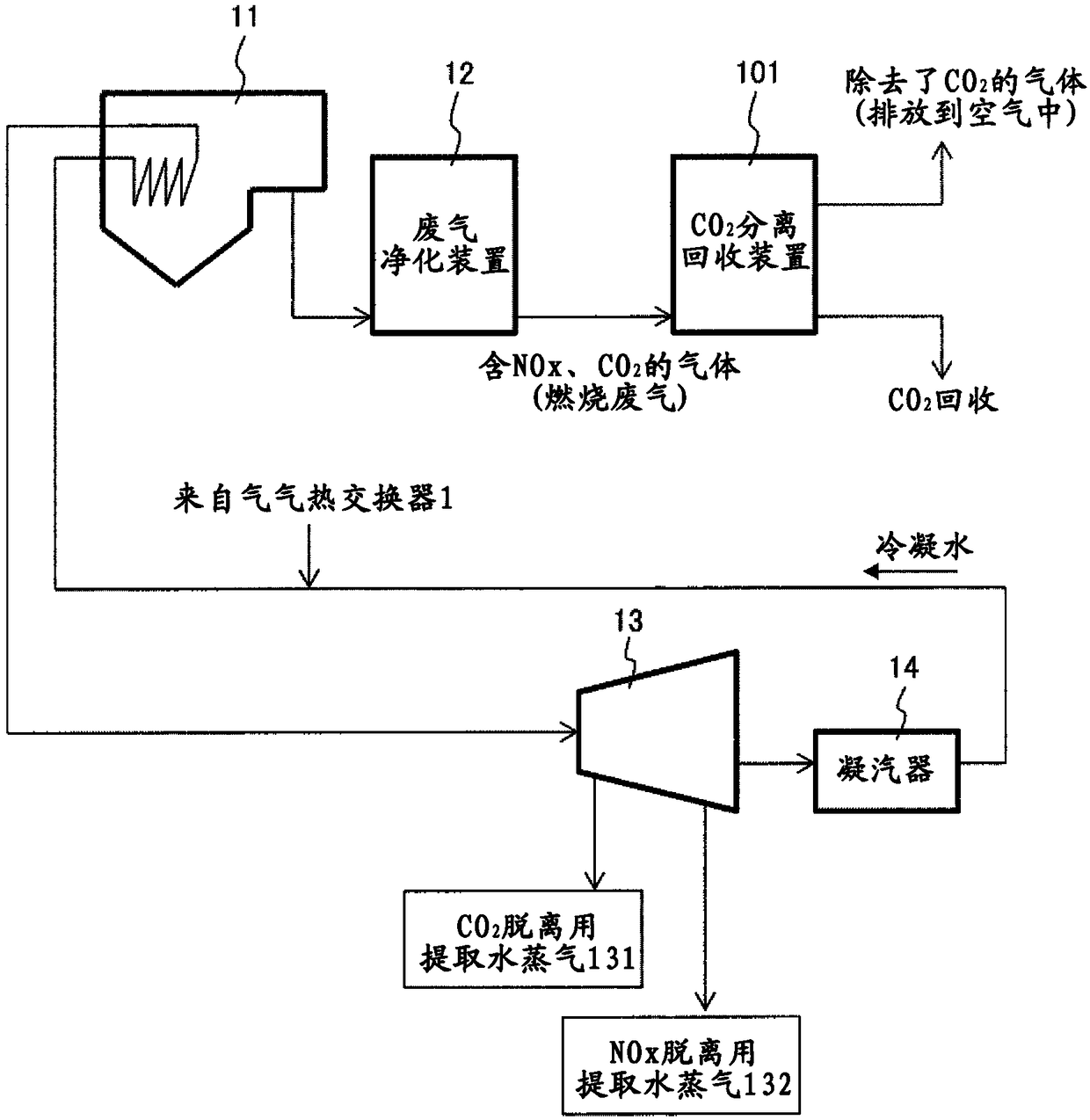

[0089] Figure 3A shows the use of CO shown in Example 1 2 The characteristics of the capture material, the separation and recovery of CO from the combustion exhaust gas of the boiler of the thermal power plant 2 The composition of the device. Typically, combustion exhaust gases contain nitrogen oxides and carbon dioxide. Combustion exhaust gas is also called gas to be processed.

[0090] In this figure, in addition to CO 2 In addition to the separation and recovery device 101, a boiler 11, an exhaust gas purification device 12, a low-pressure turbine 13 and a condenser 14 of a thermal power plant are also shown. in CO 2 The capture container of the separation and recovery device 101 contains CO 2 Capture materials. This constitutes CO 2 capture unit.

[0091] The combustion exhaust gas discharged from the boiler 11 is transported to the CO 2 Separation recovery device 101. in CO 2 In the separation and recovery unit 101, CO is removed 2 After removing the CO 2 g...

Embodiment 3

[0107] Figure 4 shows the CO in the present invention 2 In the separation and recovery unit, it is used to suppress CO 2 The structure of NOx desorption in the desorption process.

[0108] In addition to CO 2 The configuration other than the detachment step is the same as that shown in the second embodiment.

[0109] In this example, the recovered CO as the heating gas 2 circulates in the capture container 151 . The gas discharged from the capture container 151 (heated gas, desorbed from CO 2 and out of H 2 O mixed gas) after circulating in gas-gas heat exchanger 153, make it circulate in condenser 157, make H 2 O is condensed and removed. Then, the gas discharged from the condenser 157 flows through the air-gas heat exchanger 153 to perform heat exchange to increase the temperature. Then, the gas is passed through the gas-gas heat exchanger 155 to further exchange heat with the extracted water vapor 131 from the steam turbine. Here, the condenser 157 is an example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com