Dual-response amphiphilic polyphosphazene targeted drug carrier material and preparation method thereof

A dual-response, polyphosphazene technology, applied in the field of medicine, can solve the problems of human toxicity and side effects, lack of specificity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

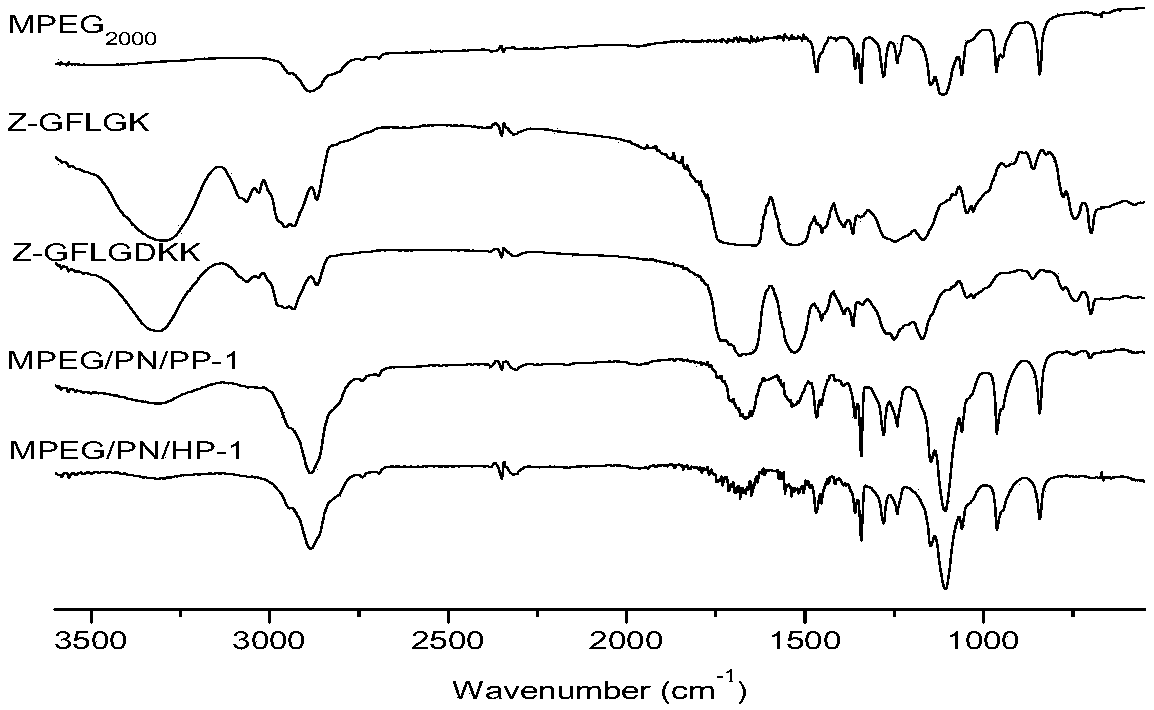

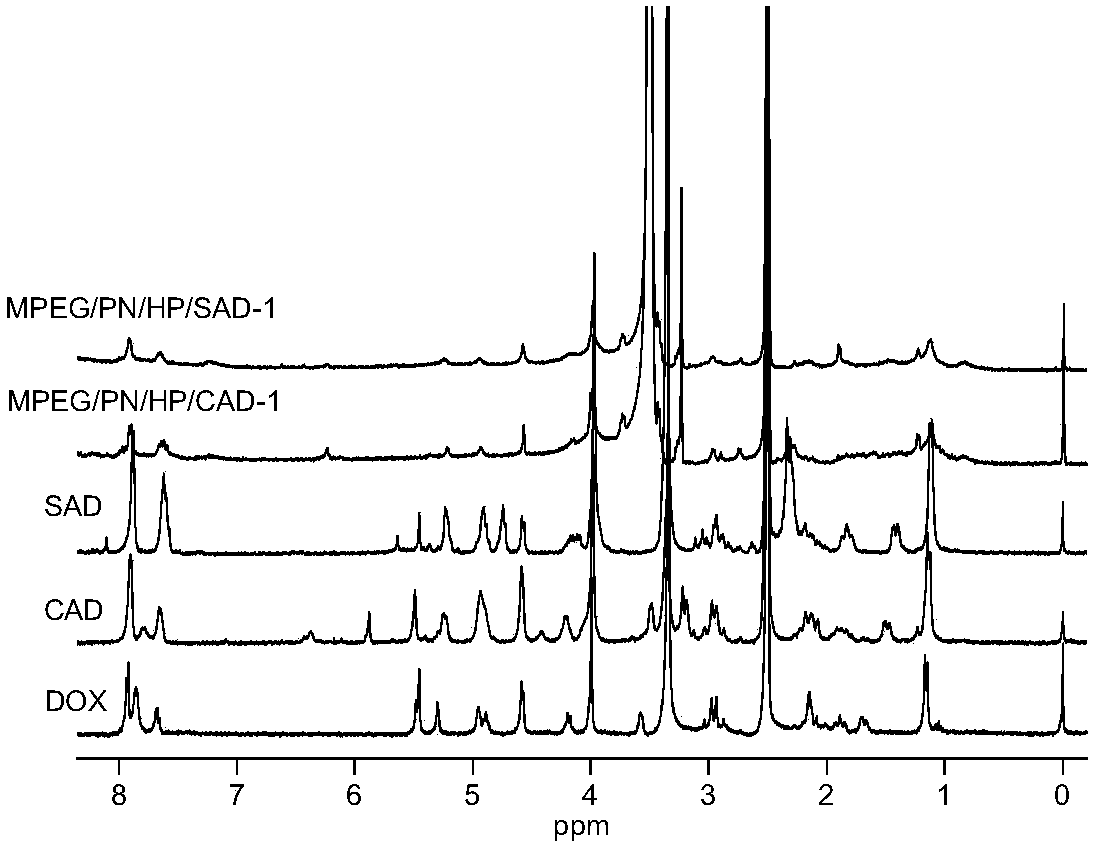

[0068] The invention provides a dual-response amphiphilic polyphosphazene-targeted drug-loaded polymer material, comprising an enzyme-responsive and pH-responsive dual-response amphiphilic polyphosphazene and at least one hydrophobic drug;

[0069] The double response type amphiphilic polyphosphazene is based on the polyphosphazene segment shown in formula (1), and is connected with a hydrophilic segment and a hydrophobic segment on the phosphorus atom; the hydrophilic The segment is polyethylene glycol monomethyl ether, and the hydrophobic segment is an enzyme-responsive pentapeptide H 2 N-GFLGK-OEt, the chemical formula is gly-phe-leu-gly-lys-OEt;

[0070]

[0071] The chemical formula of the double response type amphiphilic polyphosphazene obtained is:

[0072]

[0073] Among them, A is polyethylene glycol monomethyl ether, and B is an enzyme-responsive pentapeptide;

[0074] The hydrophobic drug is covalently bonded to the hydrophobic segment, and the hydrophobic d...

Embodiment 2

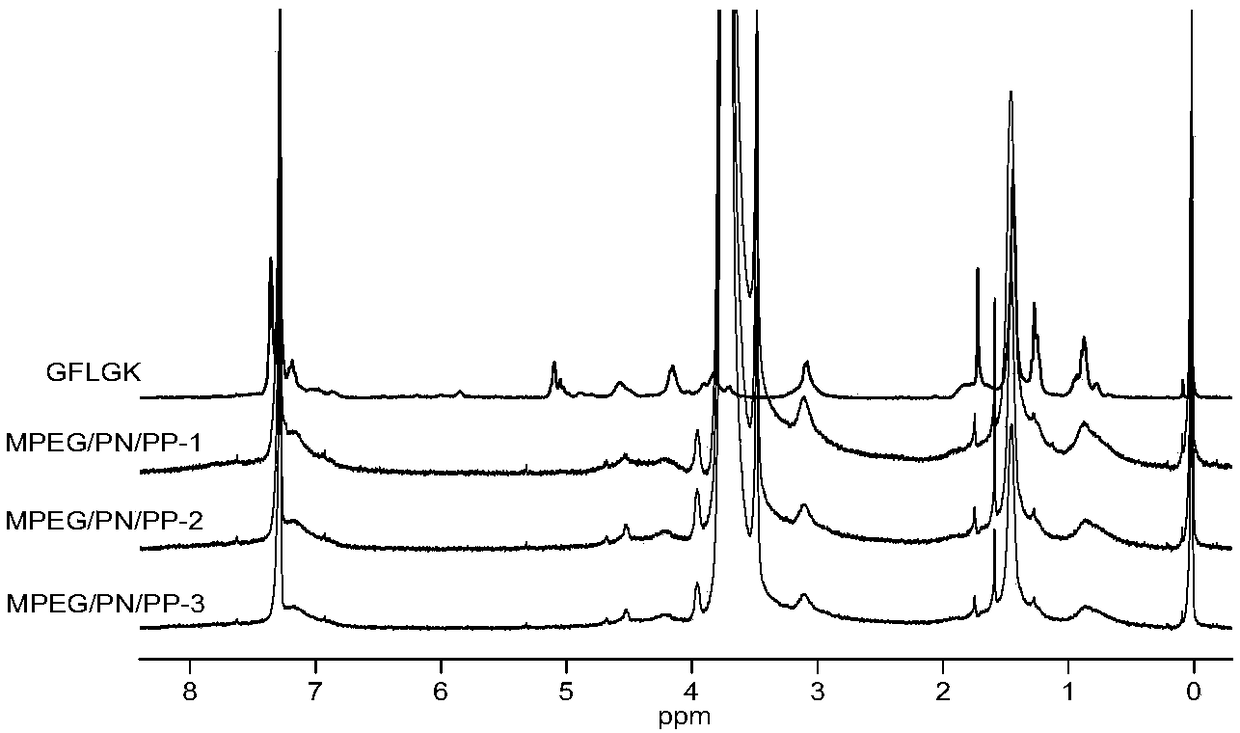

[0094] According to the preparation method of Example 1, the hydrophobic segment is designed to be a pentapeptide, and the molar ratio of MPEG and pentapeptide is 1.5:1, and the amount of each raw material component is modified therein;

[0095] In step (1), in step b, the normal temperature reaction time is 2h, in step c, according to the molar ratio of the hydrophilic segment MPEG and pentapeptide is 1.5:1, weigh the pentapeptide H after vacuum drying 2 N-GFLGK-OEt, add dropwise the tetrahydrofuran solution containing the pentapeptide and triethylamine to the above polyphosphazene-MPEG reaction solution, react at room temperature for 3h, then heat in an oil bath at 55°C, and continue the reaction for 50h, In step d, after the reaction, the oil bath was removed, cooled to room temperature, the polyphosphazene-MPEG-peptide chain reaction solution was spin-dried, then dissolved in methanol, filtered with diatomaceous earth, and centrifuged at a speed of 12000r / min Remove the in...

Embodiment 3

[0098] According to the preparation method of Example 1, the hydrophobic segment is designed to be a pentapeptide, and the molar ratio of MPEG and pentapeptide is 2.5:1, and the amount of each raw material component is modified therein;

[0099] In step (1), in step b, the normal temperature reaction time is 2h, in step c, according to the molar ratio of the hydrophilic segment MPEG and pentapeptide is 1.5:1, weigh the pentapeptide H after vacuum drying 2N-GFLGK-OEt, add dropwise the tetrahydrofuran solution containing the pentapeptide and triethylamine to the above polyphosphazene-MPEG reaction solution, react at room temperature for 3h, then heat in an oil bath at 50°C, and continue the reaction for 48h, In step d, after the reaction, the oil bath was removed, cooled to room temperature, the polyphosphazene-MPEG-peptide chain reaction solution was spin-dried, then dissolved in methanol, filtered with diatomaceous earth, and centrifuged at a speed of 11000r / min Remove the ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com