Preparation method of high performance iodine vacancy bismuth oxygen-iodine photocatalytic material and application of high performance iodine vacancy bismuth oxygen-iodine photocatalytic material in treatment of toxic organic wastewater

A technology of organic wastewater treatment and photocatalytic materials, applied in special compound water treatment, light water/sewage treatment, chemical instruments and methods, etc., can solve the problem of low separation efficiency of photogenerated carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

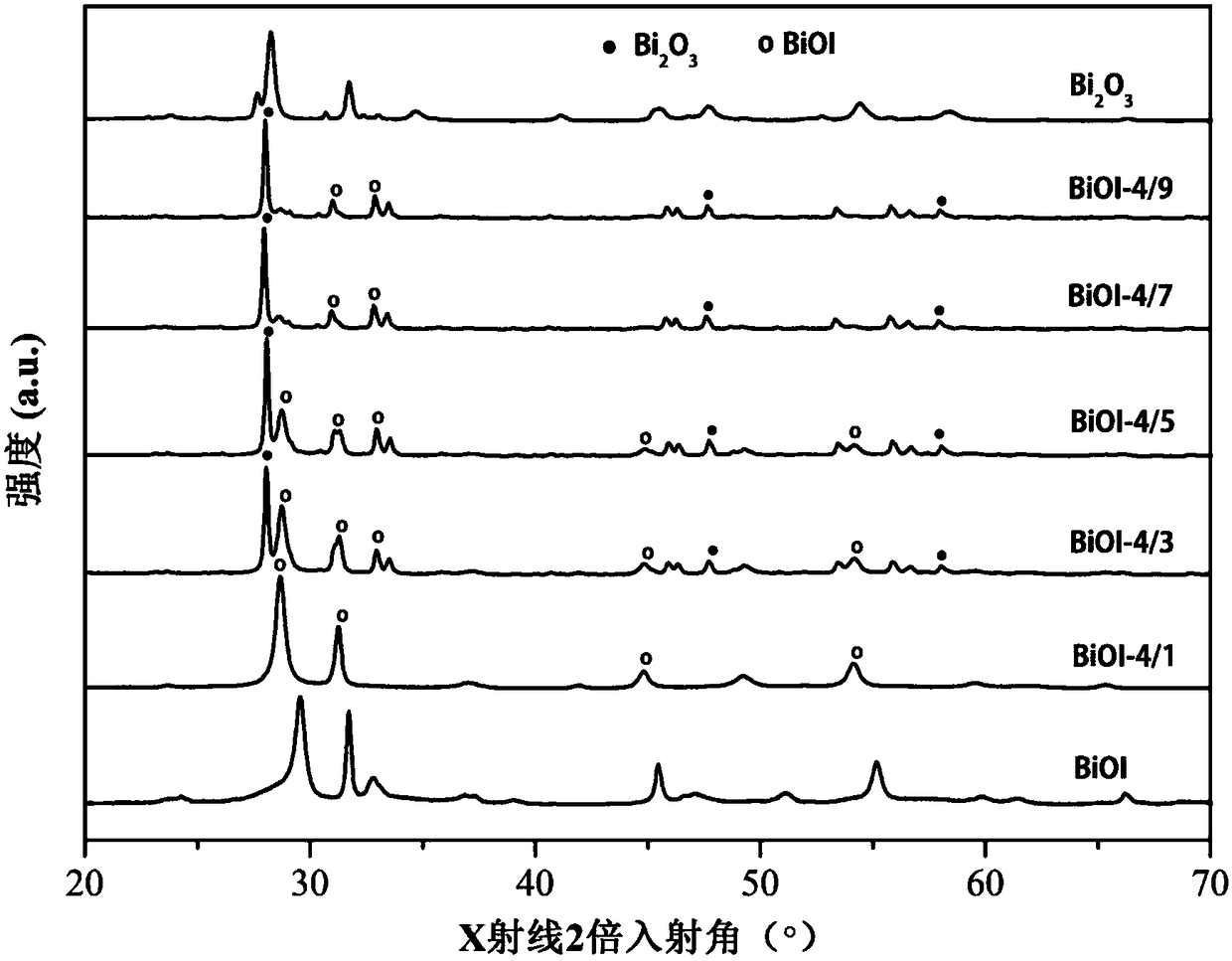

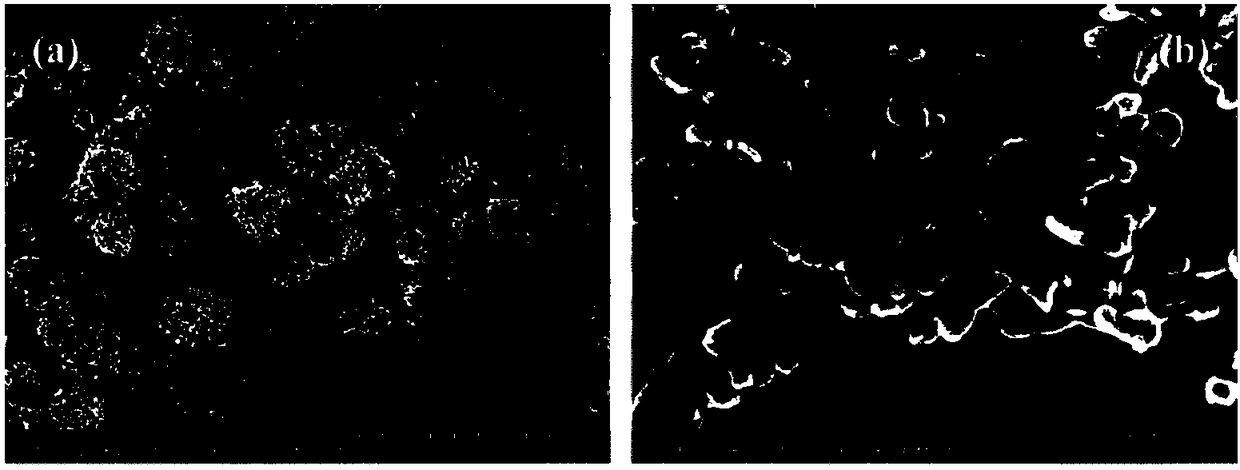

[0024] Weigh 5.5g Bi(NO 3 ) 3 ·5H 2 O and 1.9g KI were magnetically stirred with 25mL ethylene glycol for 0.5h, until completely dissolved. Then, the bismuth nitrate solution was dropped into the potassium iodide solution, and the reaction was performed with magnetic stirring for 1 h, transferred to a high-pressure reactor, and reacted at 160° C. for 12 h, and cooled naturally to room temperature. The product was washed 2-3 times with deionized water, filtered, dried at 80°C, and ground to obtain coral red BiOI.

Embodiment 2

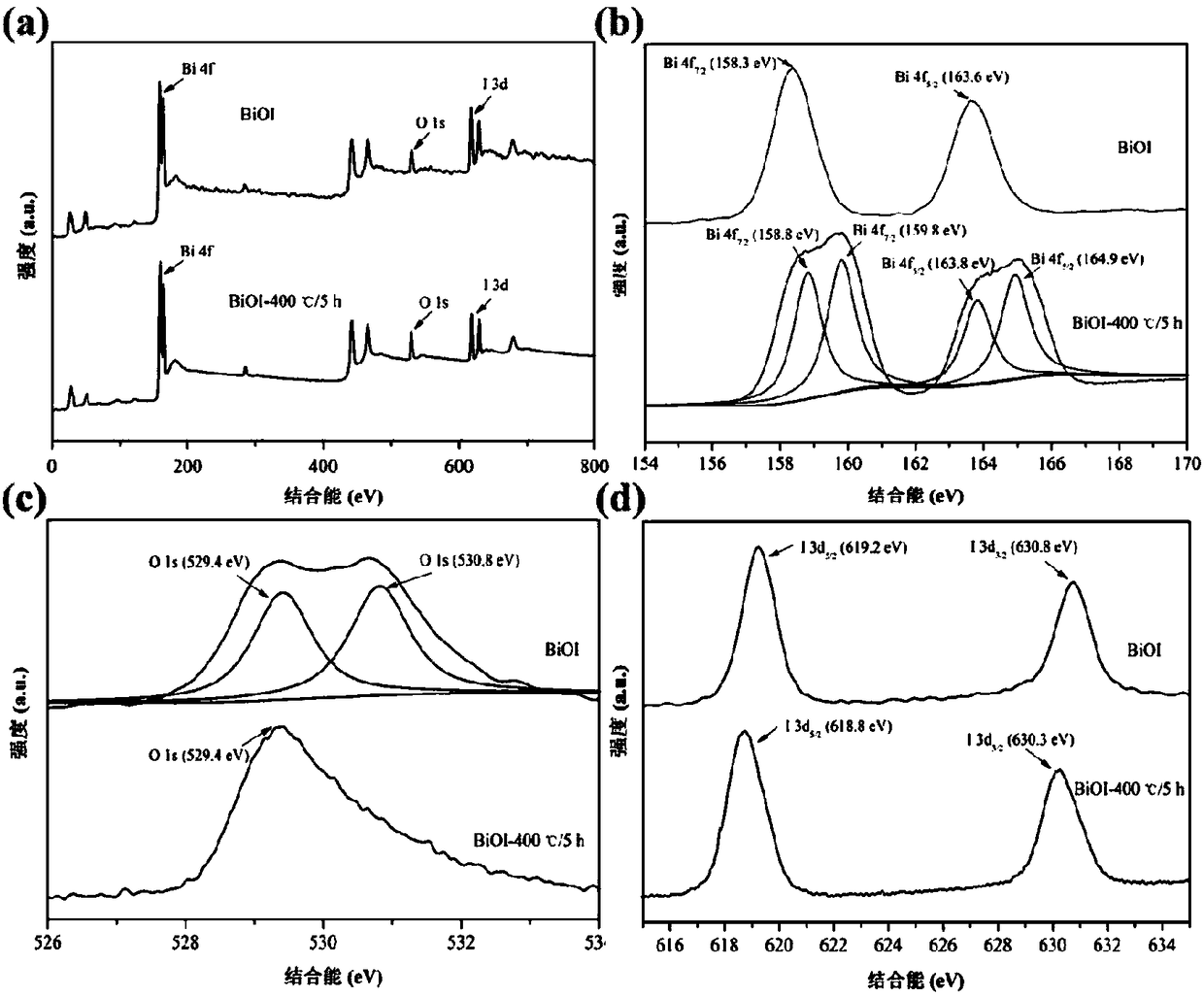

[0026] Weigh 1g of BiOI prepared in Example 1, put it into an alumina crucible, place it in a muffle furnace, heat it to 200°C at a heating rate of 5°C / min, keep this temperature for calcination for 5h, and naturally cool to room temperature , to obtain iodine vacancy bismuth oxygen iodine BiO 1.05 I 0.90 .

Embodiment 3

[0028] Weigh 1g of BiOI prepared in Example 1, put it into an alumina crucible, place it in a muffle furnace, heat it to 300°C at a heating rate of 5°C / min, keep this temperature for calcination for 5h, and naturally cool to room temperature , to obtain iodine vacancy bismuth oxygen iodine BiO 1.11 I 0.78 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com