Preparation method of nanometer grade spherical aluminum oxide

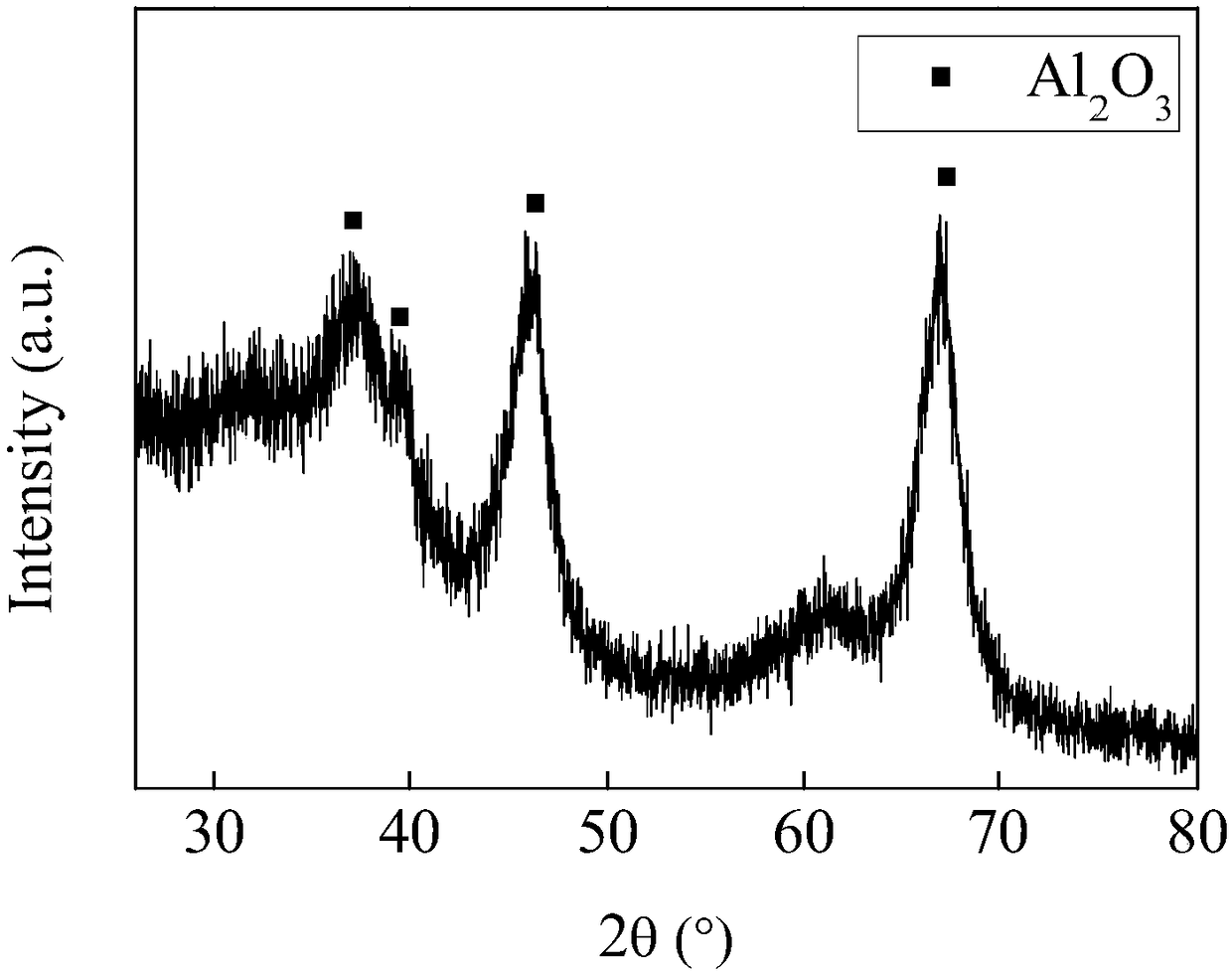

A spherical alumina, nanoscale technology, applied in the preparation of aluminum hydroxide, chemical instruments and methods, nanotechnology, etc., to achieve good application prospects, small particle size, and regular morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the nanoscale spherical alumina of the present embodiment comprises the following steps:

[0045] 1) Analytical pure Al(NO 3 ) 3 9H 2 O was added to deionized water and stirred with a glass rod to dissolve it to obtain Al 3+ Concentration is the transparent solution A of 1.2mol / L, standby; The analytically pure C 6 h 5 (NH 4 )3 o 7 2H 2 Add O into deionized water, stir it with a glass rod to dissolve it, and prepare a transparent solution B with a concentration of 0.3mol / L for subsequent use;

[0046] 2) Add a certain amount of ammonium citrate solution B to solution A, so that Al 3+ The molar ratio to citrate ions is 4:1, stir well with a glass rod to obtain solution C; add a certain amount of absolute ethanol to solution C, so that the volume ratio of solution C to ethanol is 1:1, and use glass The stick is fully stirred evenly to obtain solution D;

[0047] 3) Pour the solution D into the liner of the hydrothermal reaction kettle m...

Embodiment 2

[0051] The preparation method of the nanoscale spherical alumina particles of the present embodiment comprises the following steps:

[0052] 1) Analytical pure Al(NO 3 ) 3 9H 2 O was added to deionized water and stirred with a glass rod to dissolve it to obtain Al 3+ Concentration is the transparent solution A of 1.2mol / L, standby; The analytically pure C 6 h 5 (NH 4 ) 3 o 7 2H 2 Add O into deionized water, stir it with a glass rod to dissolve it, and prepare a transparent solution B with a concentration of 0.4mol / L for subsequent use;

[0053] 2) Add a certain amount of ammonium citrate solution B to solution A, so that Al 3+ The molar ratio to citrate ions is 3:1, stir well with a glass rod to obtain solution C; add a certain amount of absolute ethanol to solution C, so that the volume ratio of solution C to ethanol is 1:1, and use glass The stick is fully stirred evenly to obtain solution D;

[0054] 3) Pour the solution D into the liner of the hydrothermal react...

Embodiment 3

[0057] The preparation method of the nanoscale spherical alumina particles of the present embodiment comprises the following steps:

[0058] 1) Analytical pure Al(NO 3 ) 3 9H 2 O was added to deionized water and stirred with a glass rod to dissolve it to obtain Al 3+ Concentration is the transparent solution A of 1.4mol / L, standby; The analytically pure C 6 h 5 (NH 4 ) 3 o 7 2H 2 Add O into deionized water, stir it with a glass rod to dissolve it, and prepare a transparent solution B with a concentration of 0.35mol / L for subsequent use;

[0059] 2) Add a certain amount of ammonium citrate solution B to solution A, so that Al 3+ The molar ratio to citrate ions is 4:1, stir well with a glass rod to obtain solution C; add a certain amount of absolute ethanol to solution C, so that the volume ratio of solution C to ethanol is 1:1, and use glass The stick is fully stirred evenly to obtain solution D;

[0060] 3) Pour the solution D into the liner of the hydrothermal reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com