Preparation method of anti-hollowing high-adhesion strength tile adhesive

A high-bonding, tile adhesive technology, used in the field of decorative material preparation, can solve the problems of shedding, thermal deformation resistance, poor absorbing deformation stress, lack of adhesive strength and flexibility, etc., and achieves small particle size and high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

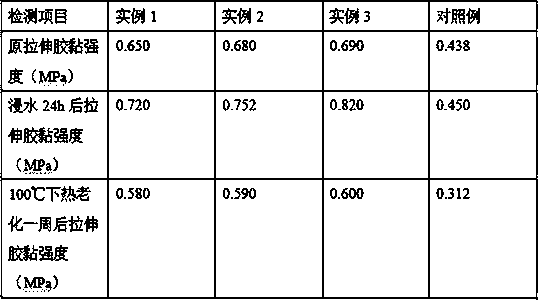

Examples

example 1

[0021] Put the ceramic tile polishing waste residue and zirconia ball milling beads into the ball milling tank according to the mass ratio of the ball to material at 30:1, then add anhydrous ethanol that is 5 times the mass of the ceramic tile polishing waste residue into the ball milling tank, and the revolution speed is 250r / min , Wet milled for 3 hours at the rotation speed of 500r / min to obtain wet milled waste residue; mix the wet milled waste residue and potassium permanganate solution with a mass fraction of 30% at a mass ratio of 1:5, and heat up to 70°C. Stir the reaction for 1 hour. After the reaction is over, filter and separate to obtain the filter residue. Mix the obtained filter residue and lemon juice at a mass ratio of 1:5 to obtain a mixture; spread the mixture on a tray, put it in a temperature of 30°C, and air relative humidity 70% of the greenhouse, let it stand for 3 days to get moldy, then transfer the moldy into a fermenter, seal and ferment at 38°C for 7...

example 2

[0023]Put the ceramic tile polishing waste residue and zirconia ball milling beads into the ball milling tank according to the mass ratio of the ball to material at 30:1, then add anhydrous ethanol that is 8 times the mass of the ceramic tile polishing waste residue into the ball milling tank, and the revolution speed is 255r / min , Wet milled for 4 hours under the condition of rotation speed of 530r / min to obtain wet milled waste residue; after mixing wet milled waste residue and potassium permanganate solution with a mass fraction of 30% at a mass ratio of 1:5, heated to 75°C, Stir the reaction for 1 hour. After the reaction is over, filter and separate to obtain the filter residue. Mix the obtained filter residue and lemon juice at a mass ratio of 1:5 to obtain a mixture; spread the mixture on a tray, put it in a temperature of 33°C, and air relative humidity 75% of the greenhouse, let it stand for 4 days to get moldy, then transfer the moldy thing into a fermenter, seal and ...

example 3

[0025] Put the ceramic tile polishing waste residue and zirconia ball milling beads into the ball milling tank according to the mass ratio of the ball to material at 30:1, then add anhydrous ethanol with 10 times the mass of the ceramic tile polishing waste residue into the ball milling tank, and the revolution speed is 260r / min , wet grinding for 4 hours under the condition of rotation speed of 550r / min to obtain wet grinding waste residue; mix the wet grinding waste residue and potassium permanganate solution with a mass fraction of 30% at a mass ratio of 1:5, and heat up to 80°C. Stir the reaction for 2 hours. After the reaction is over, filter and separate to obtain the filter residue. Mix the obtained filter residue and lemon juice at a mass ratio of 1:5 to obtain a mixture; spread the mixture on a tray, put it in a temperature of 35°C, and air relative humidity In a greenhouse with a concentration of 80%, let it stand for moldy treatment for 5 days to obtain moldy matter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com