Optothermal responsive material, method used for preparing photo-thermal driven robot from optothermal responsive material, and applications thereof

A technology of photothermal response and robotics, applied in the direction of manipulators, manufacturing tools, coatings, etc., to achieve good adaptability, improve photothermal response rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

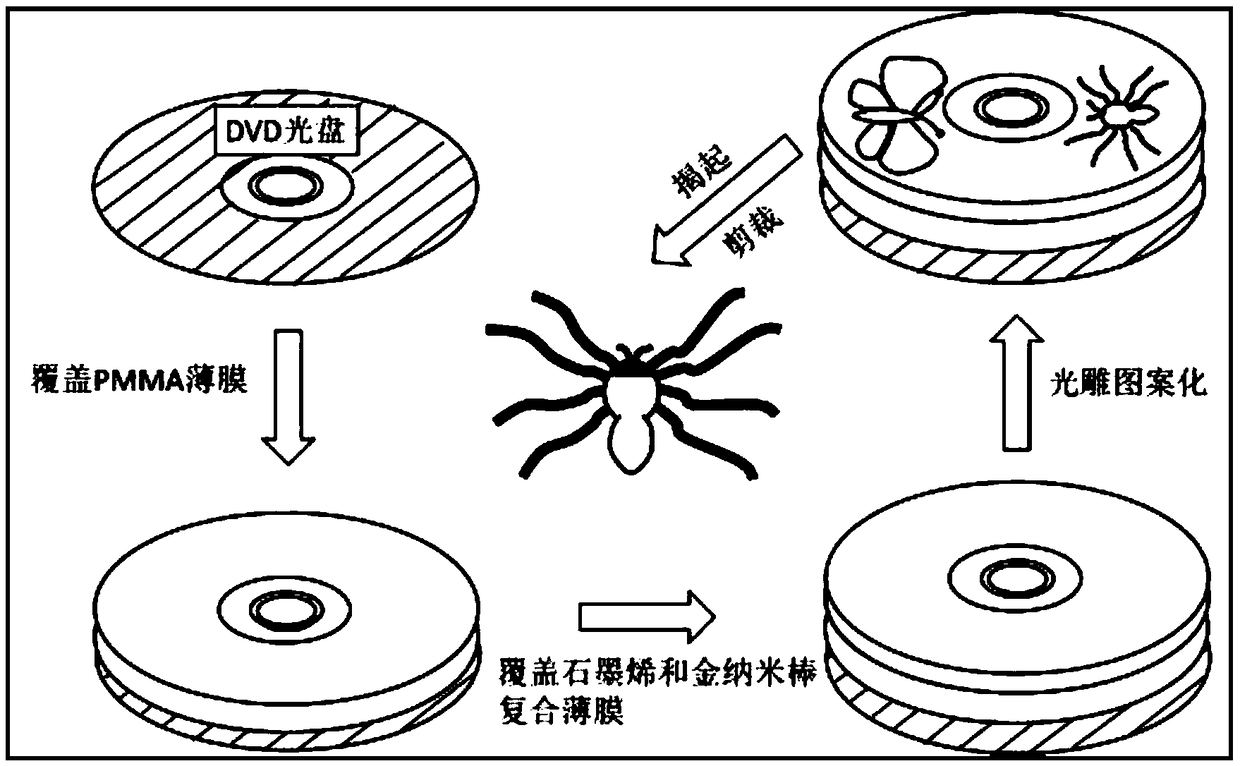

[0038] Fabrication of photothermal actuated robots by photoreduction.

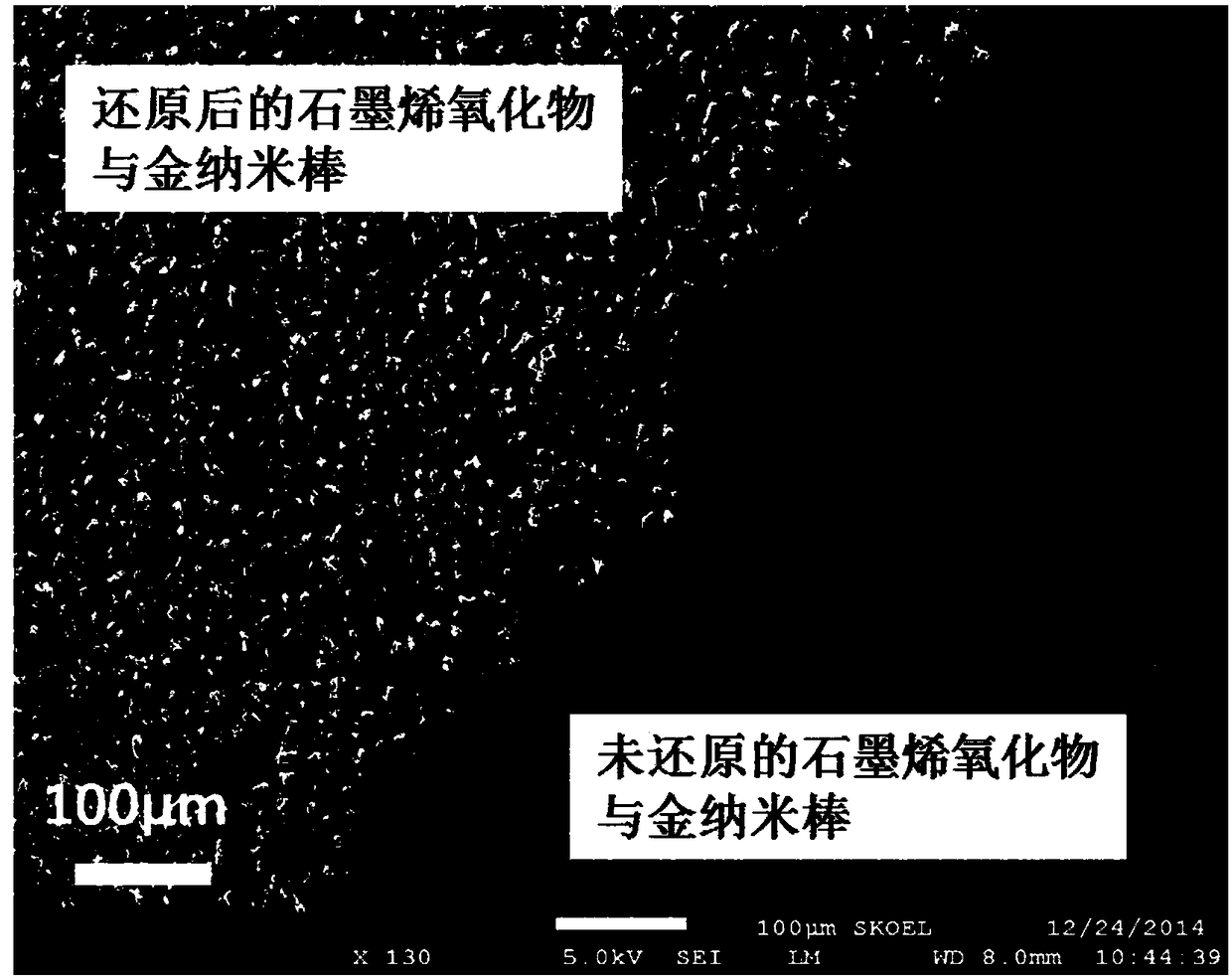

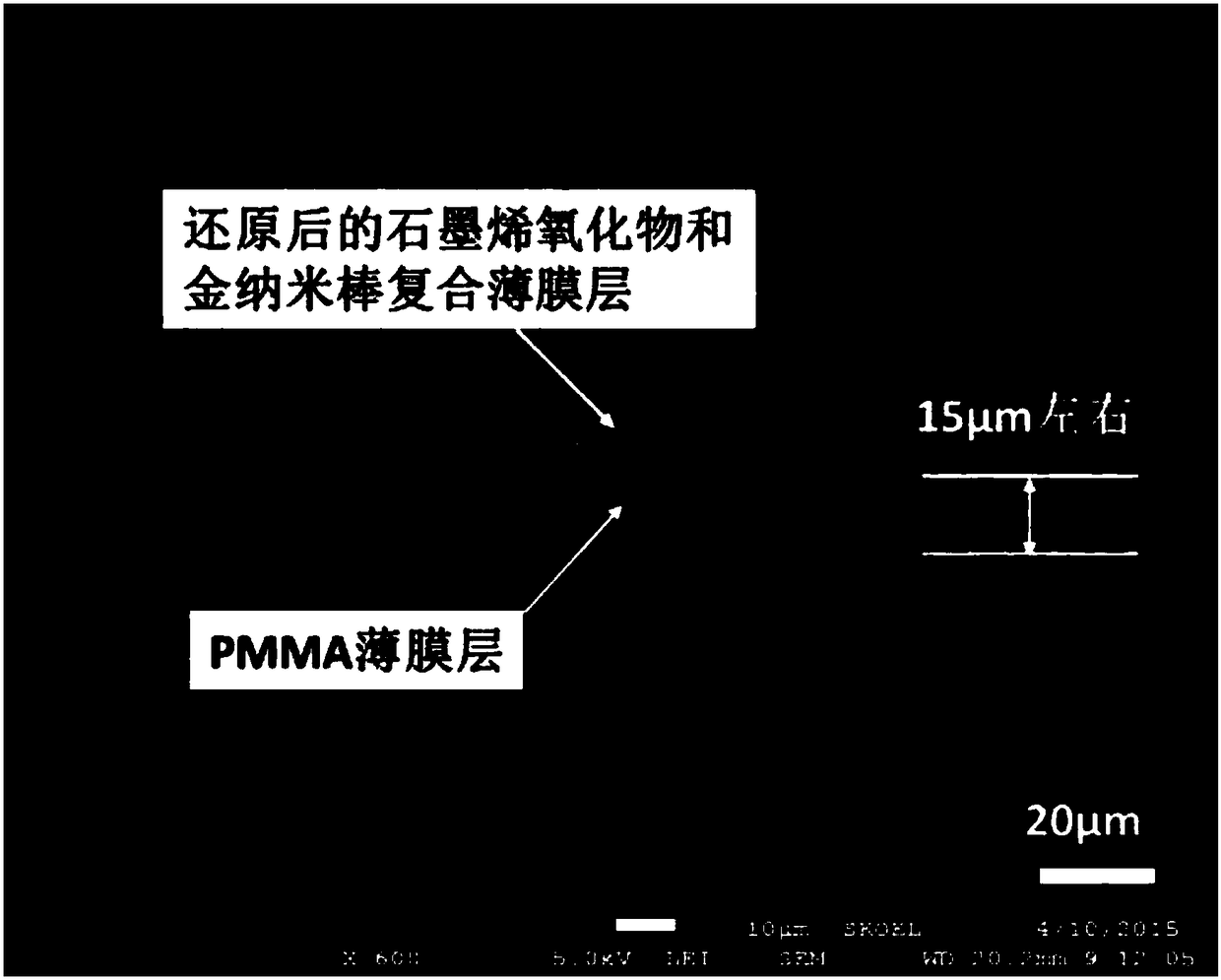

[0039] The composite nanomaterial of graphene oxide and gold nanorods is used as the basic material for the preparation of photothermal-driven robots, and the pattern design of the robot can be realized through light carving reduction; Graphene oxide in the actuator region, resulting in several photoactuator components with photothermal response. In this way, the photoreduction completes the patterning of the robot and the integration of the light driver in one step.

[0040] The method for preparing a photothermal drive robot by using light carving technology, the specific steps are as follows:

[0041] (1), synthesis of double-layer light-engraving raw material film: first, synthesize graphene oxide with Hummer's method, synthesize gold nanorod with wet chemical method, obtain the solution of graphene oxide and gold nanorod respectively; Then, two The solution is mixed with a volume ratio of 10:1, and ...

Embodiment 2

[0050] The response wavelength of the photothermally driven robot is regulated by adjusting the diameter-to-length ratio of gold nanorods.

[0051] The photothermal driven robot of the present invention has wavelength response characteristics, that is, it only responds to the laser-driven light source of a specific wavelength. This response wavelength is determined by the diameter-to-length ratio of the gold nanorods in the composite film. Therefore, by regulating the synthesis of AgNO 3 By changing the diameter-to-length ratio of the gold nanorods by changing the amount of the solution, the response wavelength of the photothermally driven robot to the driving light source (that is, the resonance wavelength of the plasmons excited on the gold nanorods) can be adjusted.

[0052] The method of adjusting the response wavelength of the photothermal driven robot by adjusting the diameter-to-length ratio of gold nanorods, the specific steps are:

[0053] (1) Synthesis of double-la...

Embodiment 3

[0059] Fabrication of a flytrap-type manipulator actuated by light and heat by light-sculpting technology.

[0060] According to the driving principle of the optical driver of the present invention, a deformed robot is designed with reference to the biological structure of the Venus flytrap, which can realize functions such as grasping.

[0061] The method for preparing a photothermally driven flytrap-type manipulator by using light carving technology, the specific steps are:

[0062] (1), the synthesis of double-layer photoengraving raw material film: with embodiment 1, used AgNO 3 The volume of the solution is 2.8 mL.

[0063](2) Photocarving reduction preparation robot: Same as in Example 1, the patterned picture used is the structure diagram of the Venus flytrap robot hand.

[0064] (3) Robot plastic surgery: firstly, lift the double-layer film from under the optical disc after light carving, and cut along the inner and outer contour lines of the light carving pattern ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com