Preparation method of expandable graphite modified petroleum resin

A technology of expanded graphite and petroleum resin, applied in the field of preparation of expandable graphite modified petroleum resin, can solve the problems of easy aging, can not meet the requirements of the material market, petroleum resin cannot be used, etc., and achieves the effect of improving thermal oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

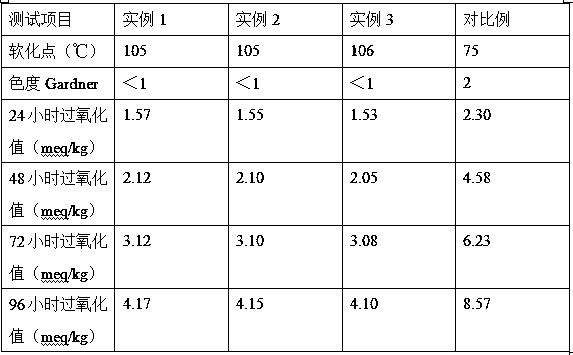

Examples

Embodiment Construction

[0019] Weigh 36-42g of natural flake graphite and grind it for 11-13min to obtain natural flake graphite powder, then mix concentrated sulfuric acid solution with a mass fraction of 85%, hydrogen peroxide with a concentration of 0.5mol / L and Acetic anhydride was mixed and stirred for 12 to 15 minutes to obtain a mixed solution; the natural flake graphite powder, mixed solution and potassium permanganate were mixed and stirred for 27 to 30 minutes in a mass ratio of 7:2:1, and the filtrate was filtered to obtain a filter residue. Put the filter residue into an oven, dry at a temperature of 75-81°C for 32-36 minutes, cool to room temperature naturally, grind for 16-20 minutes, and then pass through a 85-mesh sieve to obtain self-made expandable graphite powder; calculated in parts by weight , weigh 24-32 parts of xylene, 10-12 parts of dicyclopentadiene, 9-11 parts of isoprene, 3-5 parts of styrene and 1-3 parts of n-pentene and mix them in the reactor , stirred for 12-16 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com