Heat resistant plastic bearing material and its prepn. method

A plastic bearing and heat-resistant technology, which is applied in the field of composite materials of polymer compounds, can solve the problems of high melt viscosity and difficult injection molding, etc., achieve a wide range of applications, achieve reinforcement, and improve the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

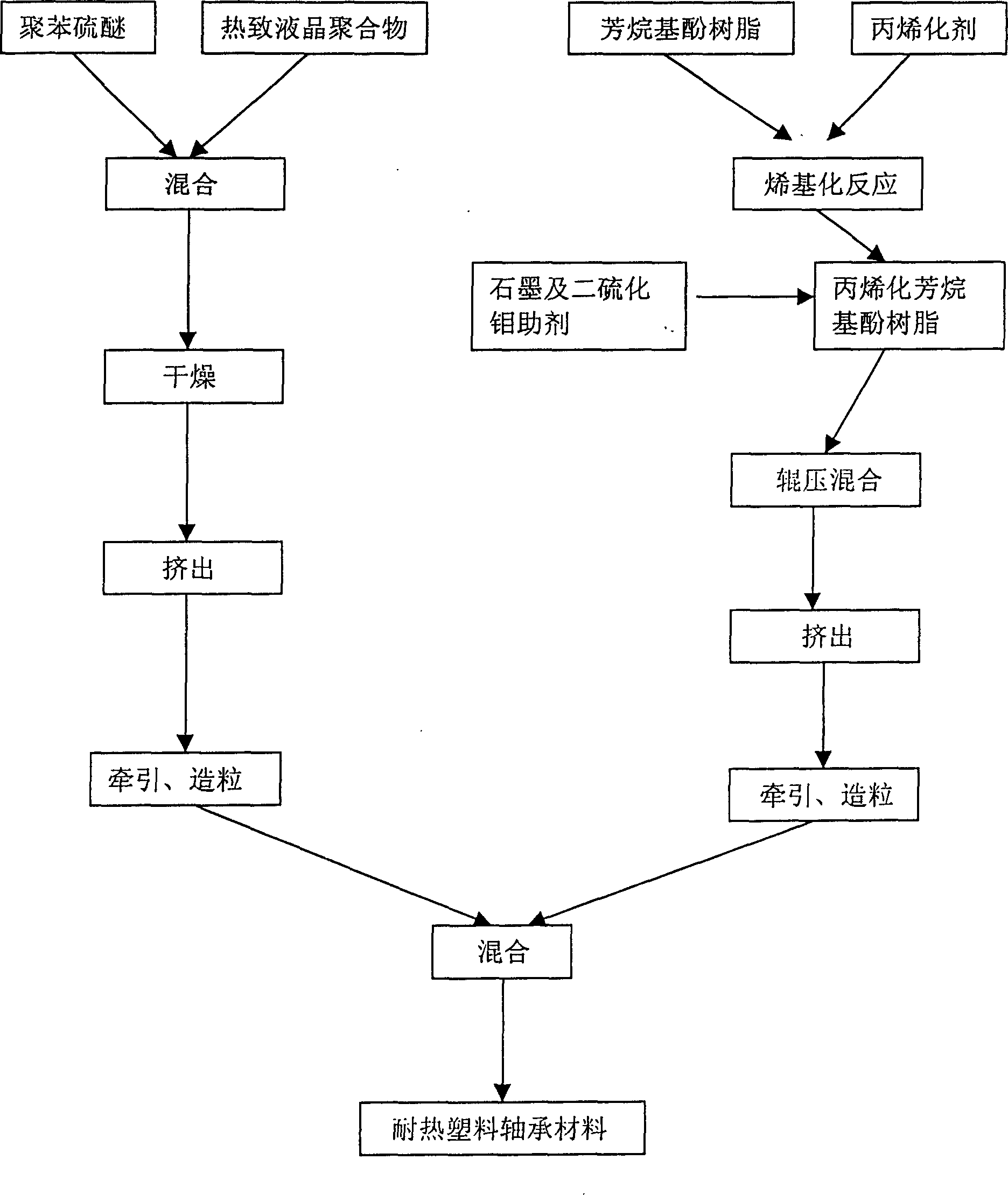

Method used

Image

Examples

Embodiment 1

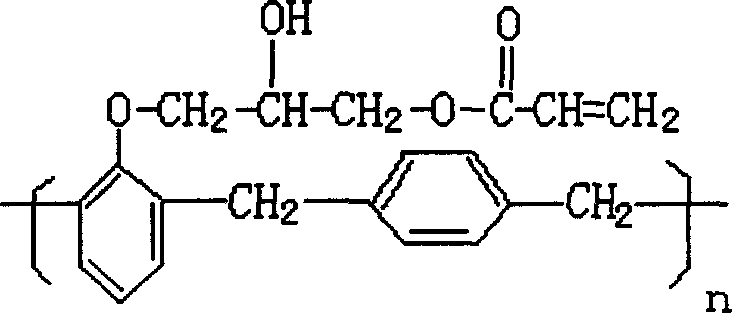

[0017] Embodiment 1: the preparation of propenated aralkylphenol resin

[0018] Add 100 liters of methyl ethyl ketone-xylene mixed solvent (the volume ratio of methyl ethyl ketone and xylene is 30:70) in the reactor that device has stirrer, reflux condenser, 100 kilograms of epoxy aralkylphenol resins (molecular weight 2000 , purchased from Northwestern Polytechnical University), heated and stirred to dissolve, heated up to 90±5°C, slowly dripped acrylic acid (the amount of acrylic acid was calculated according to the equimolar ratio with epoxy aralkylphenol resin), and maintained at 90±5°C React at 5°C for 2.5-3 hours, and stop the reaction until more than 95% of the epoxy groups have participated in the reaction. After washing and separating, put it in an enamel plate and dry it in a vacuum drying oven with a vacuum degree of 600-650 mm Hg. After drying to a basic constant weight, the prepared propylene-based aralkylphenol resin (molecular weight: 2400) , stored for later u...

Embodiment 2

[0019] Embodiment 2: Preparation of heat-resistant plastic bearing material

[0020] (1) Mix 90kg of polyphenylene sulfide and 10kg of thermotropic liquid crystal polymer. After mixing, dry the mixture in an oven at 120°C for 12 hours. After cooling to room temperature with the oven, add it to the extruder Carry out melt blending. During blending, the temperature of the barrel is divided into four sections. The temperature of each section from the feeding section to the extrusion port is 250°C, 270°C, 300°C, and 320°C. Extrude twice, and the extruded product is drawn Thinning and granulation are the first material granules, which are set aside.

[0021] (2) Take by weighing 100kg, 6kg and 16kg of the propylene-based aralkylphenol resin, graphite and molybdenum disulfide prepared in Example 1 and mix them, roll and mix them for 2 minutes at 85-90°C on a roller press , after rolling and mixing evenly, it is then added to the extruder for melt blending. The temperature of the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com