Lanthanum sulfonate-calixarene complex antioxidant, and preparation method and application thereof

A technology of lanthanum sulfonate-cup and antioxidant, which is applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of small steric hindrance of phenolic hydroxyl groups and affect the anti-oxidation performance of polymer materials, and achieve high ratio and excellent anti-oxidation Oxidation ability, effect of inhibiting volatilization and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

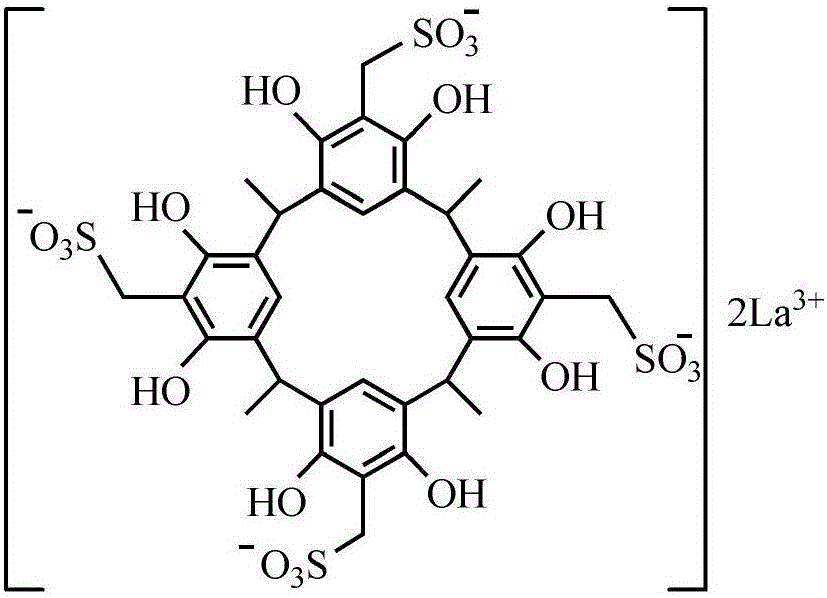

[0031] (1) Synthesis of lanthanum sulfonate-calixarene complex antioxidant:

[0032] 1g of C‐methyl resorcinol calix[4]arene (synthesized according to literature: Ito H, Nakayama T, SherwoodM, Miller D, Ueda M.Characterization and lithographic application of calix[4]resorcinarene derivatives.Chemistry of Materials , 2008,20(1):341‐356) and 1g of anhydrous sodium sulfite were dissolved in 5g of water, 1g of formaldehyde solution with a mass concentration of 37% was added, and reacted at 90°C for 4 hours under nitrogen, then cooled to room temperature, dropwise Add concentrated hydrochloric acid solution to adjust the pH value to 7, add acetone to obtain a precipitate, filter the precipitate and dry it in vacuum at 60°C to constant weight to obtain a sodium sulfonate-calixarene complex intermediate.

[0033] Dissolve 1g of sodium sulfonate-calixarene complex intermediate and 2g of lanthanum chloride hydrate in water, react at 80°C under nitrogen for 8 hours, then cool to room te...

Embodiment 2

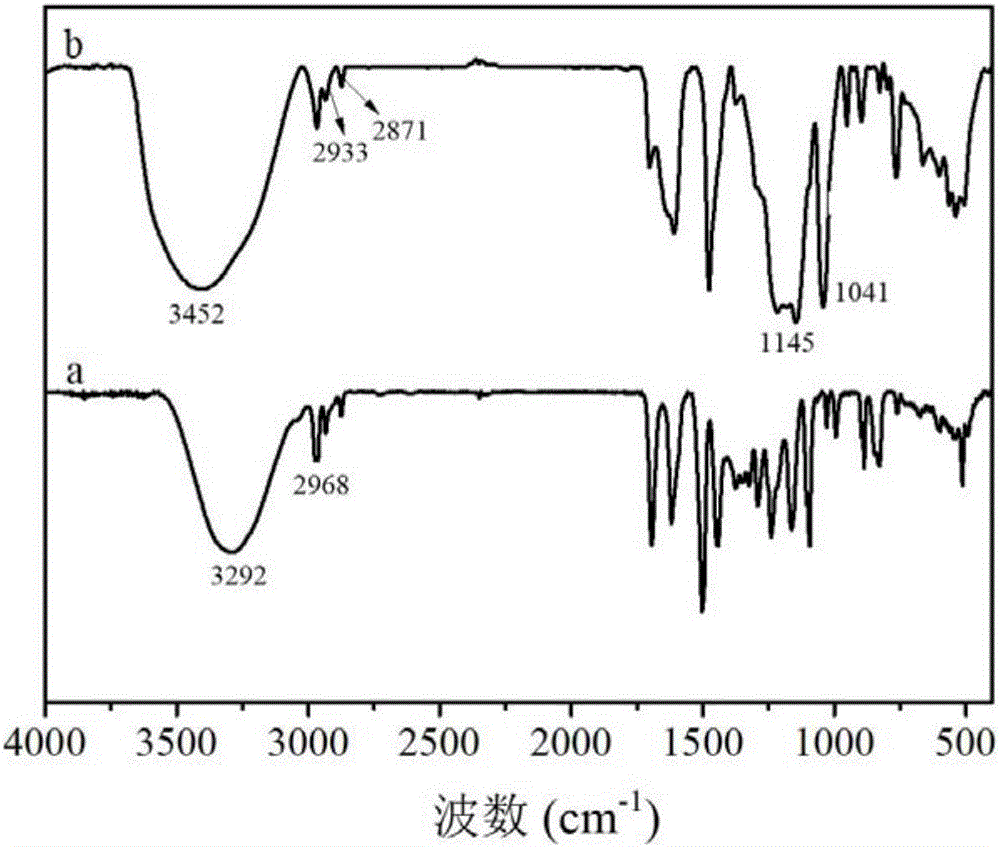

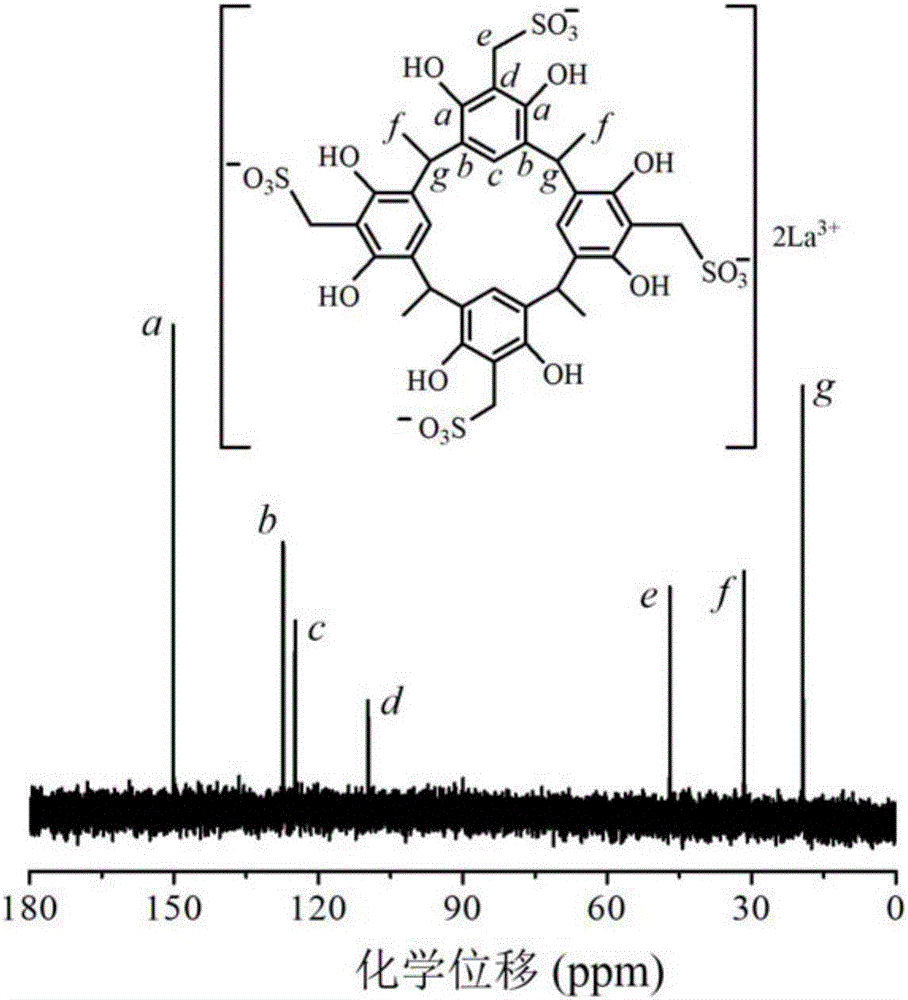

[0039] The difference between this embodiment and Example 1 is: the mass ratio of C‐methylresorcinol calix[4]arene and anhydrous sodium sulfate is changed to 1:2, that is, the consumption of anhydrous sodium sulfate is changed The mass ratio of C‐methylresorcinol calix[4]arene and 37% formaldehyde solution is changed to 1:0.5, that is, the quality of 37% formaldehyde solution is changed to 0.5g; C‐methylresorcinol The mass ratio of phenolic calix[4]arene and water is changed to 1:3, that is, the quality of water is changed to 3g; the quality of lanthanum chloride hydrate is changed to 0.5 times of the quality of sodium sulfonate-calixarene complex intermediate, That is, change it to 0.5g; change the reaction temperature in the first step to 80°C, and change the reaction time to 6 hours; change the reaction temperature to 85°C in the second step, and change the reaction time to 4 hours; the first and second steps of vacuum drying The temperature was changed to 50°C. FT-IR and ...

Embodiment 3

[0042] The difference between this embodiment and Example 1 is: the mass ratio of C‐methylresorcinol calix[4]arenes and anhydrous sodium sulfate is changed to 1:0.5, that is, the amount of anhydrous sodium sulfate is changed The mass ratio of C‐methylresorcinol calix[4]arene and 37% formaldehyde solution was changed to 1:2, that is, the quality of 37% formaldehyde solution was changed to 2g; C‐methylresorcinol The mass ratio of phenolic calix[4]arenes and water is changed to 1:5, that is, the quality of water is changed to 5g; That is, change it to 3g; change the reaction temperature in the first step to 95°C, and change the reaction time to 2 hours; change the reaction temperature to 70°C, and change the reaction time to 10 hours in the second step. FT-IR and mass spectrometry are basically the same figure 1 , 2 , indicating the successful preparation of lanthanum sulfonate-calixarene complex antioxidant.

[0043] The thermal and oxidative aging resistance properties of na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com