Polyacrylate solvent-type acid-base-resistant pressure-sensitive adhesive tape and preparation method and application thereof

A polyacrylate, solvent-based technology, used in adhesive types, pressure-sensitive films/sheets, ester copolymer adhesives, etc., can solve the problem that product quality cannot meet application requirements, acid and alkali resistance and temperature resistance Gap and other issues, to avoid appearance defects, improve overall performance, and enhance the formation of polymer networks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

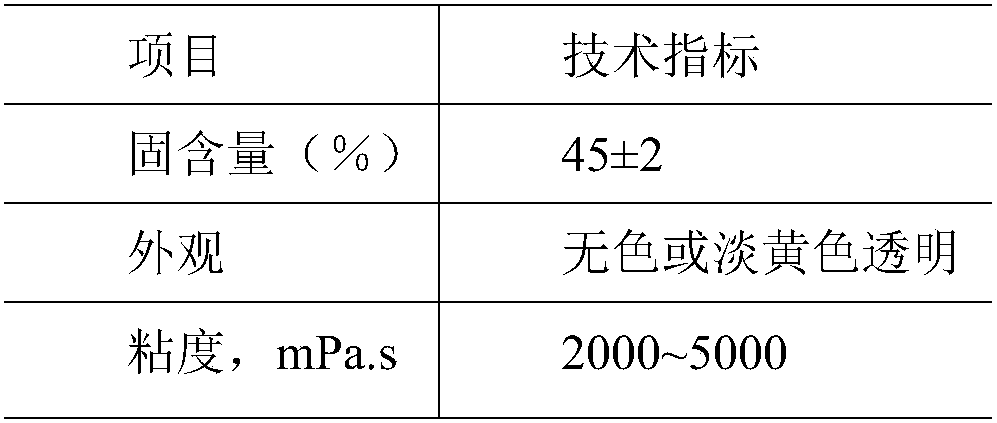

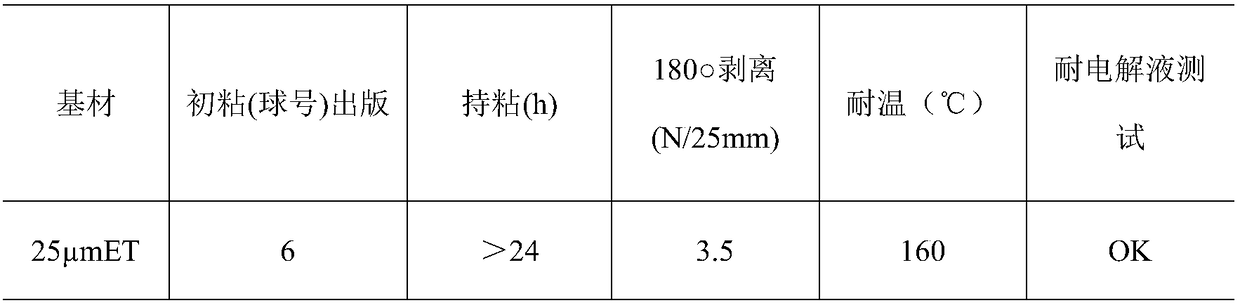

Embodiment 1

[0038] 1. Preparation method:

[0039] (1) Put 400 parts of butyl acrylate, 8 parts of acrylic acid, 4 parts of methacrylic acid, 6 parts of hydroxypropyl acrylate, 12 parts of methyl methacrylate, and 10 parts of lauryl acrylate in a stirring tank and mix them to obtain monomer mixture.

[0040] (2) Weigh 100 parts of xylene, 400 parts of ethyl acetate and 0.03 part of n-dodecyl mercaptan at the bottom of the reaction kettle as the bottom material.

[0041] (3) Weigh 1 part of benzoyl peroxide and dissolve it in 50 parts of butyl acetate to completely prepare the initiator, and divide it into three parts according to the mass ratio of 10:5:2;

[0042] (4) The temperature of the reaction kettle is raised to 78-82°C of the solution, 30 parts of the initiator are added, and 132 parts of the monomer mixture of step 1 are added at the same time, and kept for 10 minutes; 308 parts of the remaining monomer mixture in step 1 are added dropwise while 15 parts of the initiator Adding...

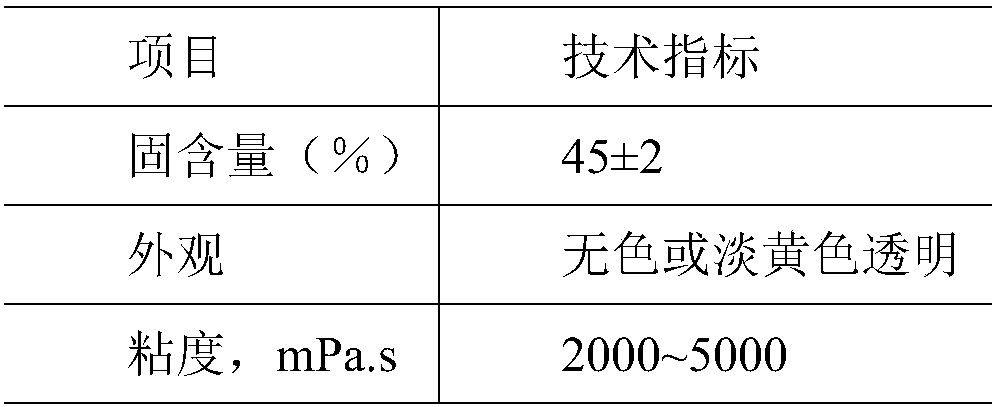

Embodiment 2

[0057] 1. Preparation method:

[0058] (1) Put 360 parts of isooctyl acrylate, 8 parts of acrylic acid, 4 parts of methacrylic acid, 6 parts of hydroxypropyl acrylate, 30 parts of methyl methacrylate, 20 parts of lauryl acrylate and 22 parts of vinyl acetate in a stirring The kettle was stirred and mixed to obtain a monomer mixture.

[0059] (2) Weigh 50 parts of toluene, 450 parts of ethyl acetate and 0.03 part of n-dodecyl mercaptan at the bottom of the reaction kettle as the bottom material.

[0060] (3) Weigh 1.2 parts of benzoyl peroxide and dissolve in 50 parts of butyl acetate to completely prepare the initiator, and divide it into three parts according to the mass ratio of 10:5:2;

[0061] (4) The reaction kettle is heated up to the solution reflux temperature of 78-82°C, 30.3 parts of initiator are added, and 135 parts of the monomer mixture in step 1 are added at the same time, and the temperature is kept at 78-82°C for 10 minutes; the remaining monomer in step 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com