Immobilized lipase and preparation method thereof

A technology for immobilizing lipase and lipase enzyme, which is applied in biochemical equipment and methods, immobilized on/in organic carriers, enzymes, etc., to achieve good storage stability, good pH tolerance, and high reuse. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Obtaining of immobilized lipase

[0037] 1.1 Effect of different epoxy resins on lipase immobilization

[0038] Take 1g of different epoxy resins (epoxy resins LXEP-120, LX-1000EP, ES-1, ES-3, ES-5, ES-7), add 4mL enzyme solution (50mmol / L phosphoric acid at pH=7.0 Dissolve in sodium buffer solution, enzyme solution concentration 2mg / mL, centrifuge at 10000r / min for 12min), place in a shaker at 25°C, fix at 150rpm for 12h. It can be seen from Table 1 that the fixation effect of epoxy resin LXEP-120 is the best, and the recovery rate of enzyme activity reaches 12.21%.

[0039] Table 1 Immobilization effect of different epoxy resins

[0040]

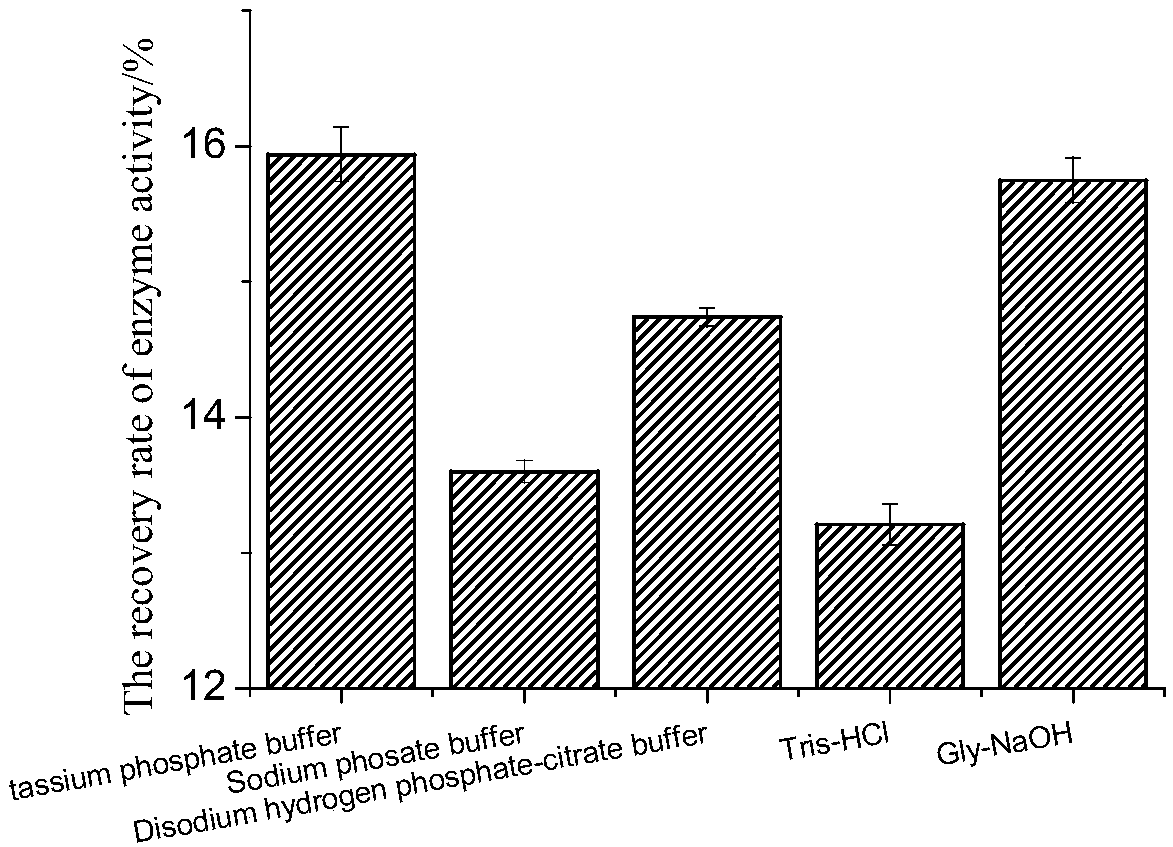

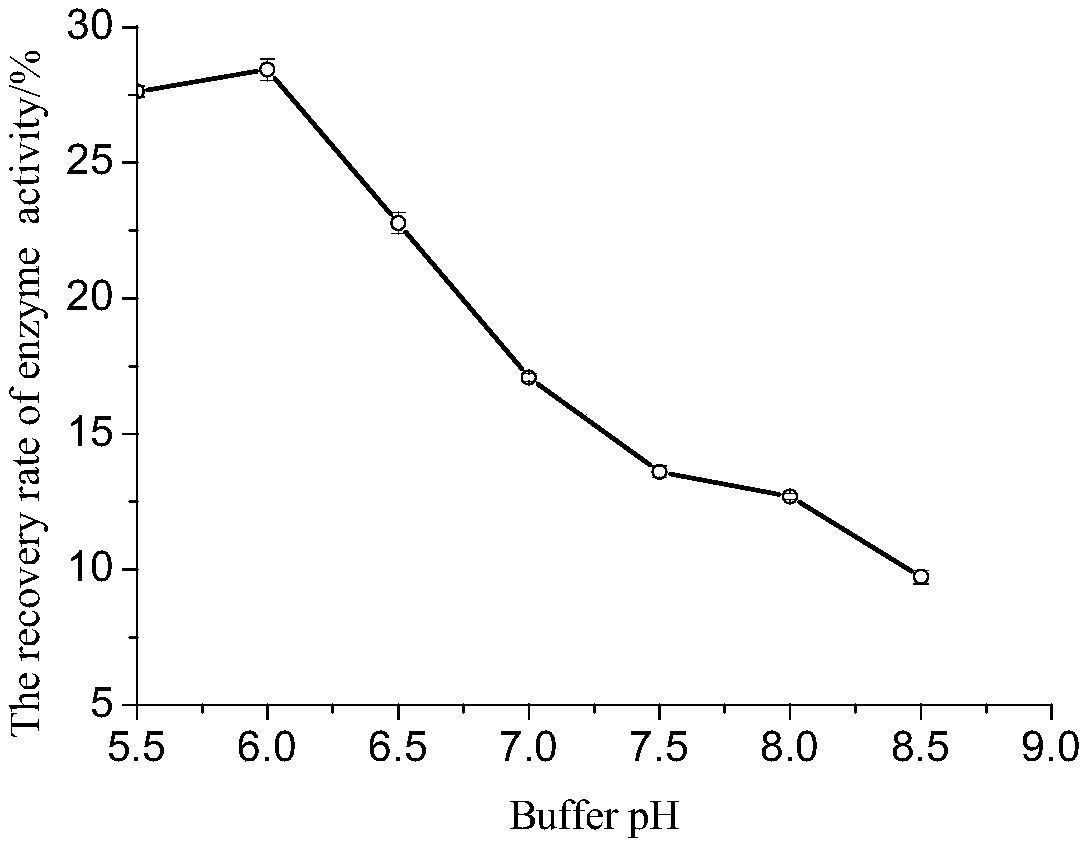

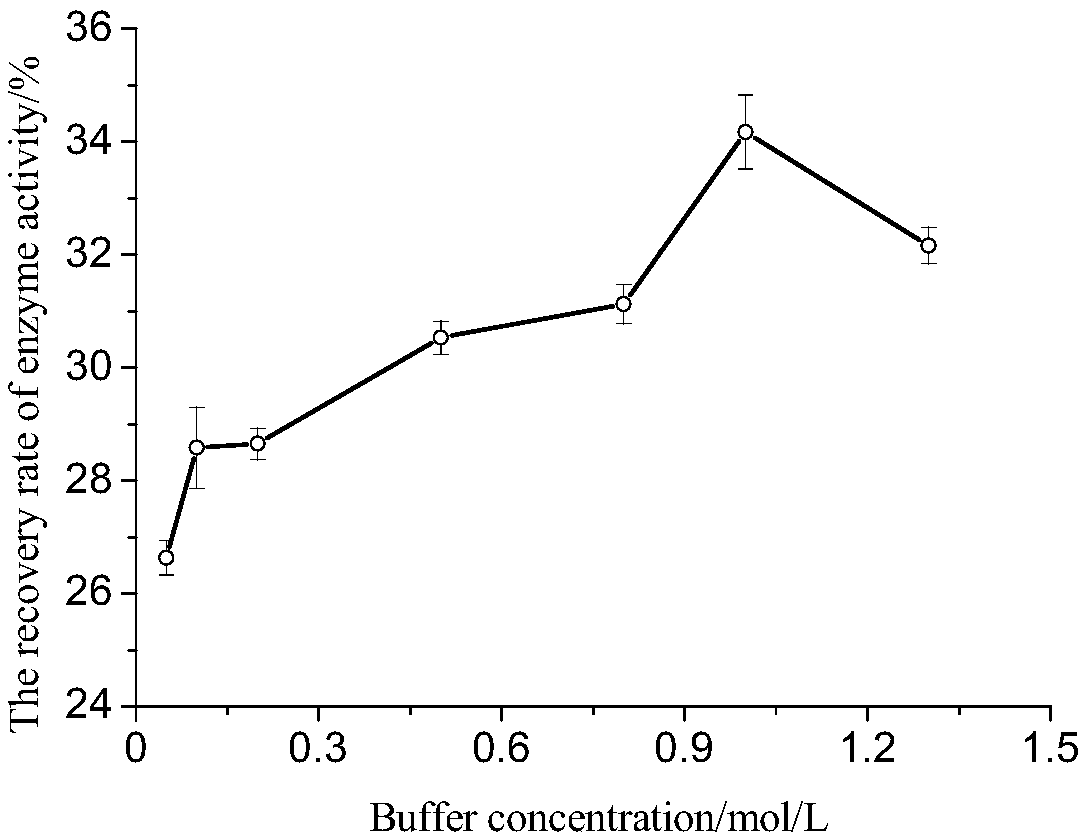

[0041] 1.2 Effect of different immobilization buffers on lipase immobilization

[0042]Potassium phosphate buffer solution, sodium phosphate buffer solution, citric acid-disodium hydrogen phosphate buffer solution, Tris-HCl buffer solution, glycine-sodium hydroxide buffer solution with a pH of 8.0 were respective...

Embodiment 2

[0053] Embodiment 2: the enzymatic property comparison of epoxy resin immobilized lipase and free enzyme

[0054] In this embodiment, epoxy resin immobilized lipase is prepared by the following method:

[0055] Use 1.0mol / L of potassium phosphate buffer solution with a pH of 6.0 to dissolve lipase enzyme powder to prepare an enzyme solution with a concentration of 2.0mg / mL, centrifuge at 10000r / min to obtain the supernatant as the enzyme solution, and accurately weigh 5.0g of the model as The epoxy resin of LXEP-120 was placed in 4mL enzyme solution, immobilized at 150rpm and 22°C for 12h, then washed three times with 1.0mol / L potassium phosphate buffer solution with a pH of 6.0, filtered with suction, and placed at 40°C. ℃ drying to obtain immobilized lipase. The enzyme activity of the prepared immobilized lipase is about 400U / g, and the recovery rate of the enzyme activity reaches 92.79%.

[0056] 2.1 The optimal reaction pH of immobilized lipase and free lipase

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com