Tagetes erecta fermenting method

A treatment method, marigold technology, applied in the direction of fermentation, microbial-based methods, biochemical equipment and methods, etc., can solve the problems of cumbersome steps, underutilized lactic acid, waste, etc., and achieve the effect of ensuring the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises the following steps:

[0029]A. Preparation of lactic acid bacteria liquid: Weigh 5g lactose, 20g glucose, 10g peptone, 10g beef extract, 5g yeast powder, 1mL Tween-80, 5g sodium acetate, 2g dipotassium hydrogen phosphate, 2g ammonium citrate, 0.2 g of magnesium sulfate and 0.05 g of manganese sulfate are added to 1L of water, and sterilized by high-pressure steam at 110-120°C for 25-40 minutes to obtain a liquid enrichment medium, and then inoculate the liquid enrichment medium with a mass percentage of 1- 5% lactic acid bacteria strains, cultivated at 25-40°C, the number of effective viable bacteria after cultivation is at least 10 billion / mL.

[0030] B. Fermentation: First, pre-mix the lactic acid bacteria liquid, calcium source compound and marigold flower raw materials according to the mass ratio of 1: (20-100): (200-800) to obtain the pre-mixed raw materials, and then spread them on the bottom of the fermentation tank One layer o...

Embodiment 1

[0033] A method for fermenting marigolds, comprising the process of fermenting marigolds with microorganisms, the fermentation raw materials include marigold flowers, calcium source compounds and lactic acid bacteria liquid, and at the same time, fermented exudates containing calcium lactate and chrysanthemum residues are obtained.

[0034] The preparation method comprises the following steps:

[0035] A. Preparation of lactic acid bacteria liquid: Weigh 5g lactose, 20g glucose, 10g peptone, 10g beef extract, 5g yeast powder, 1mL Tween-80, 5g sodium acetate, 2g dipotassium hydrogen phosphate, 2g ammonium citrate, 0.2 g of magnesium sulfate and 0.05 g of manganese sulfate were added to 1L of water, and sterilized by high-pressure steam at 110°C for 25 minutes to obtain a liquid enrichment medium, and then inoculate the liquid enrichment medium with 1% Layse milk Bacillus (Lactobacillus leichmannii) strain, cultivated at 25°C, the effective number of viable bacteria after cultiv...

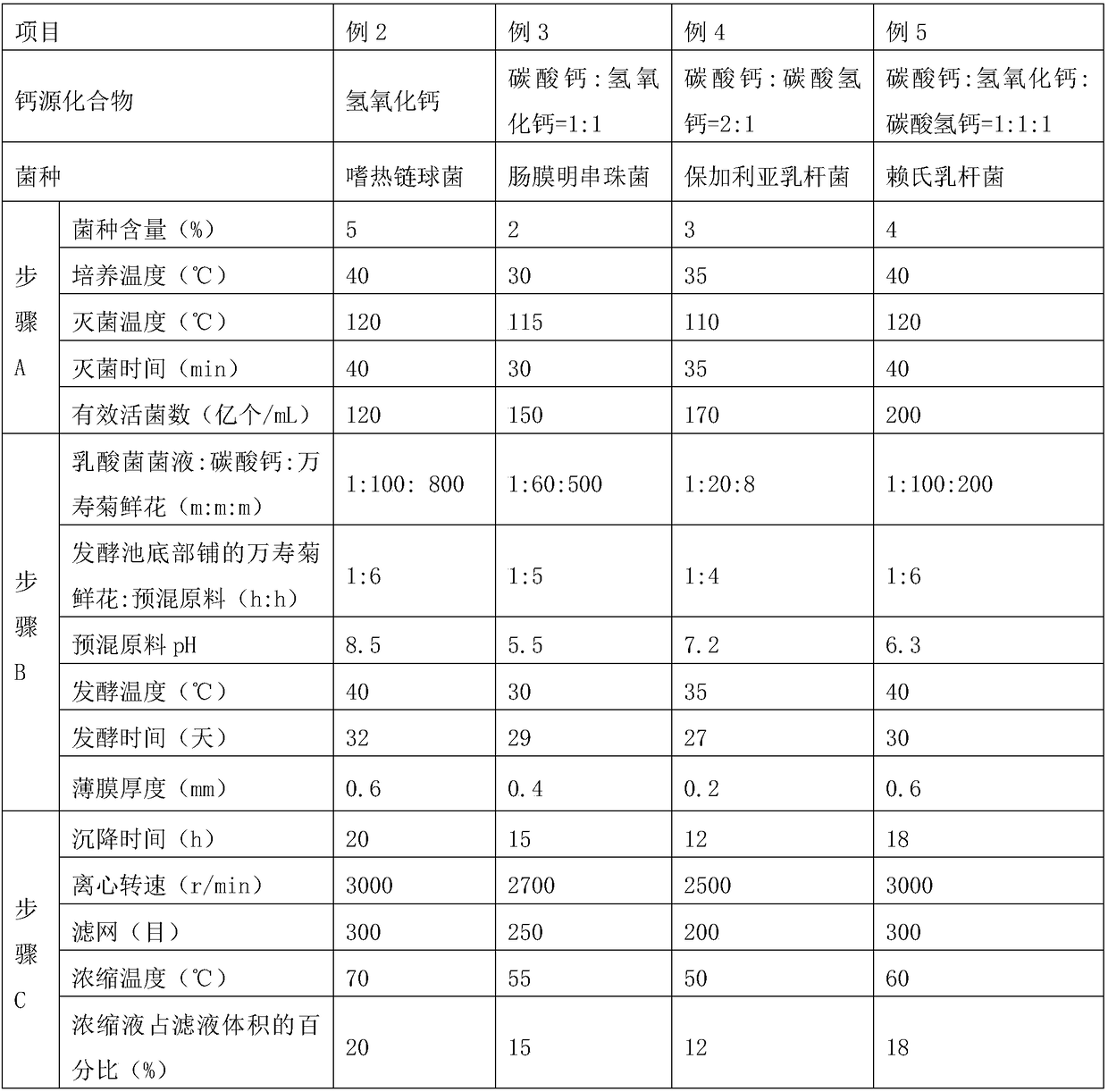

Embodiment 2~5

[0039] Embodiment 2~5 is identical with above-mentioned production process step, and difference is process parameter, or the fermented bacterial classification of choosing, as shown in table 1 below, wherein, lactic acid bacteria bacterium liquid: calcium carbonate: marigold fresh flower is each material The mass ratio of marigold flowers spread at the bottom of the fermentation tank: the premixed raw material is the height ratio of the two substances.

[0040] Table 1

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com