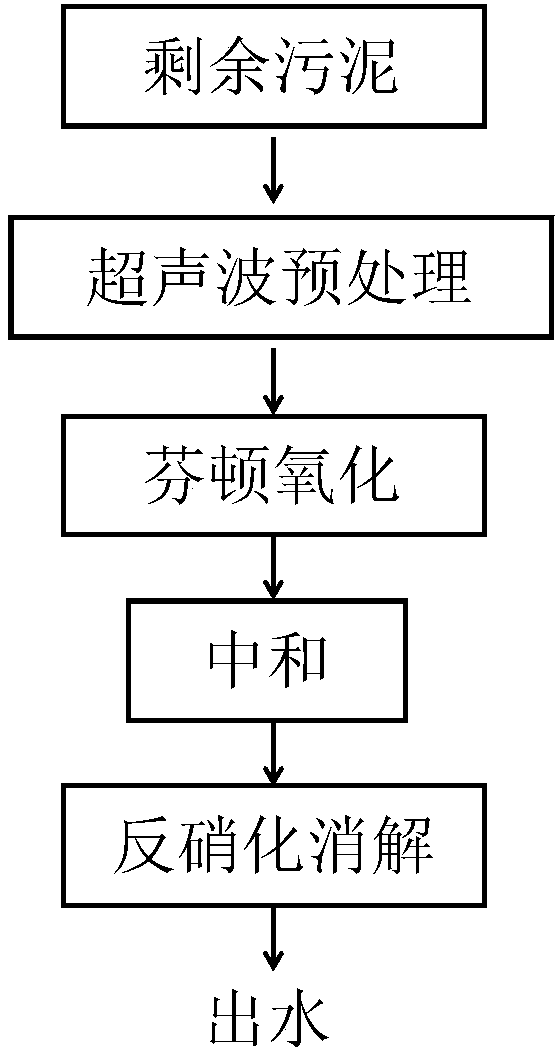

Method for treating excess activated sludge by using ultrasonic wave and Fenton reaction

A technology of excess sludge and Fenton reaction, which is applied in the direction of oxidation treatment of sludge, chemical instruments and methods, sludge treatment, etc., can solve the problems of energy waste and limited application, and achieve the improvement of treatment efficiency, cost saving, and obvious social and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

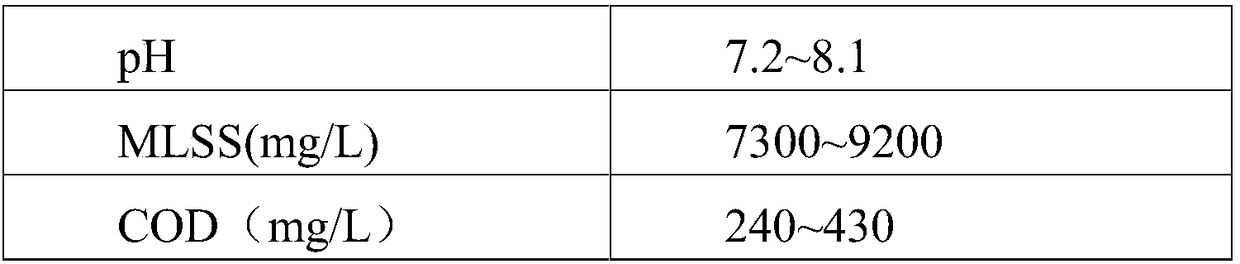

[0054] For the residual sludge of a certain enterprise, the MLSS is 7300mg / L, the COD contained in the sewage is 240mg / L, and the pH is 7.2. The treatment steps are as follows:

[0055] Step 1: Ultrasonic pretreatment of excess sludge, ultrasonic treatment of excess sludge, ultrasonic intensity 0.3W / mL, ultrasonic time 10min;

[0056] Step 2: Fenton oxidation, the remaining sludge after the above pretreatment enters the Fenton oxidation reaction tank, adds hydrochloric acid, adjusts the pH to 3.5, and the added ferrous ion concentration is 20mg / L and H 2 o 2 The concentration is 3000mg / L, and the reaction is 2h under magnetic stirring at 100rpm;

[0057] Step 3: Neutralize, add KOH to the remaining sludge after Fenton oxidation treatment, adjust the pH to 6, and it is determined that the COD in the remaining sludge is 4300mg / L at this time;

[0058] Step 4: Denitrification and denitrification digestion, the remaining sludge after neutralization is returned to the denitrifica...

Embodiment 2

[0061] For the residual sludge of a certain enterprise, the MLSS is 9200mg / L, the COD contained in the sewage is 430mg / L, and the pH is 8.1. The treatment steps are as follows:

[0062] Step 1: Ultrasonic pretreatment of excess sludge, ultrasonic treatment of excess sludge, ultrasonic intensity 0.6W / mL, ultrasonic time 20min;

[0063] Step 2: Fenton oxidation, the remaining sludge after the above pretreatment enters the Fenton oxidation reaction tank, adds hydrochloric acid, adjusts the pH to 4, and the added ferrous ion concentration is 30mg / L and H 2 o 2 The concentration is 5000mg / L, and the reaction is 3h under 100rpm magnetic stirring;

[0064] Step 3: Neutralize, add NaOH to the remaining sludge after Fenton oxidation treatment, adjust the pH to 7, and it is determined that the COD in the remaining sludge is 6300mg / L at this time;

[0065] Step 4: Denitrification and denitrification digestion, the remaining sludge after neutralization is returned to the denitrification...

Embodiment 3

[0068] For the residual sludge of a certain enterprise, the MLSS is 8400mg / L, the COD contained in the sewage is 350mg / L, and the pH is 7.5. The treatment steps are as follows:

[0069] Step 1: Ultrasonic pretreatment of excess sludge, ultrasonic treatment of excess sludge, ultrasonic intensity 0.4W / mL, ultrasonic time 16min;

[0070] Step 2: Fenton oxidation, the remaining sludge after the above pretreatment enters the Fenton oxidation reaction tank, and hydrochloric acid is added to adjust the pH to 3.7, and the added ferrous ion concentration is 25mg / L and H 2 o 2 The concentration is 4000mg / L, and the reaction is 2.5h under 100rpm magnetic stirring;

[0071] Step 3: Neutralize, add NaOH to the remaining sludge after Fenton oxidation treatment, adjust the pH to 6.5, and it is determined that the COD in the remaining sludge is 4900mg / L at this time;

[0072] Step 4: Denitrification and denitrification digestion, the remaining sludge after neutralization is returned to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com