Fresh-keeping particles used for preparing film or blister sheet and preparation method of particles

A technology of particles and plastic sheets, which is applied in the field of fresh-keeping particles of films or blister sheets, can solve the problems of short shelf life of fresh-keeping films that cannot meet market demand, high cost of fresh-keeping films, difficult to promote, and unsatisfactory fresh-keeping effects, etc., to achieve the purpose of inhibiting bacteria The effect of breeding, prolonging the shelf life and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

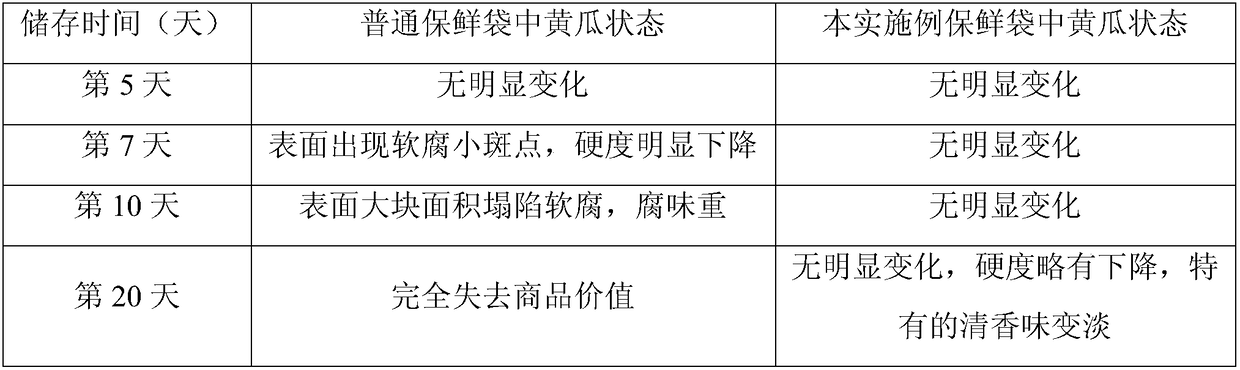

Embodiment 1

[0024] Take by weighing 35kg natural clinoptilolite powder (particle diameter is 80nm), 8kg ZSM-5 molecular sieve (particle diameter is 80nm), 3kg silicon dioxide (particle diameter is 80nm), 1kg zinc oxide (particle diameter is 80nm), 1kg natural Trehalose (particle size is 100nm), 0.5kg of epoxy silane coupling agent Z6040 is added in the high-speed mixer, 3000r / min high-speed stirring at 110 ℃ for 10 minutes for activation treatment; then add 2kg of calcium stearate, 2.5kg N-phenylmaleimide and 40kg low-density polyethylene resin (LDPE, softening point temperature is 180 ℃) continue to stir for 10 minutes, pour in the twin-screw extruder after mixing evenly, pass through at 180 ℃ temperature After melting and kneading, extrude and granulate through granulation equipment at 210° C., and dry to obtain fresh-keeping granules with a total weight of 93 kg.

[0025] The prepared fresh-keeping particles are mixed with low-density polyethylene resin LDPE according to a weight ratio...

Embodiment 2

[0031] The fresh-keeping particles prepared in Example 1 were mixed with the low-density polyethylene resin LDPE at a weight ratio of 1:8, and melted and blown to obtain a blister sheet. The prepared plastic sheet is made into a fresh-keeping box after being blistered, and the application experiment is done under the same conditions as the ordinary blister box.

[0032] The cherries are divided into two portions, each portion of 2.5 kg, put into a common blister box and a fresh-keeping box of this embodiment respectively, cover the lids, and store at room temperature (15-20° C.). See Table 2 for visual observation and taste taste.

[0033] Table 2 Fresh-keeping status and mouthfeel changes of cherries during fresh-keeping

[0034] Storage time (days)

Embodiment 3

[0036] Take by weighing 30kg natural clinoptilolite powder (particle diameter is 80nm), 7kg ZSM-5 molecular sieve (particle diameter is 80nm), 2kg silicon dioxide (particle diameter is 80nm), 2kg zinc oxide (particle diameter is 80nm), 1.5kg Add natural trehalose (particle size: 100nm), 1kg epoxy silane coupling agent Z6040 into the high-speed mixer, stir in the high-speed mixer at 110°C for 10 minutes for activation treatment, the speed is 3000r / min, and then add 1kg Calcium stearate, 3.5kgN-phenylmaleimide and 30kg low-density polyethylene resin continued to stir for 10 minutes, poured in the twin-screw extruder after mixing uniformly, after melting and kneading at a temperature of 180°C, The granulation equipment extruded and granulated at 220°C, and dried to obtain fresh-keeping granules with a total weight of 78kg.

[0037] The prepared fresh-keeping particles are mixed with the low-density polyethylene resin at a weight ratio of 1:9, melted and blown to obtain a fresh-ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com