Induction assisted shot blasting and thinning laser additive manufacturing method of light alloy crystal grains

A laser additive and light alloy technology, applied in metal material coating process, coating, etc., can solve problems such as prominent anisotropy and poor comprehensive mechanical properties of formed parts, so as to improve fatigue strength and eliminate internal tissue defects , the effect of promoting the spheroidization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

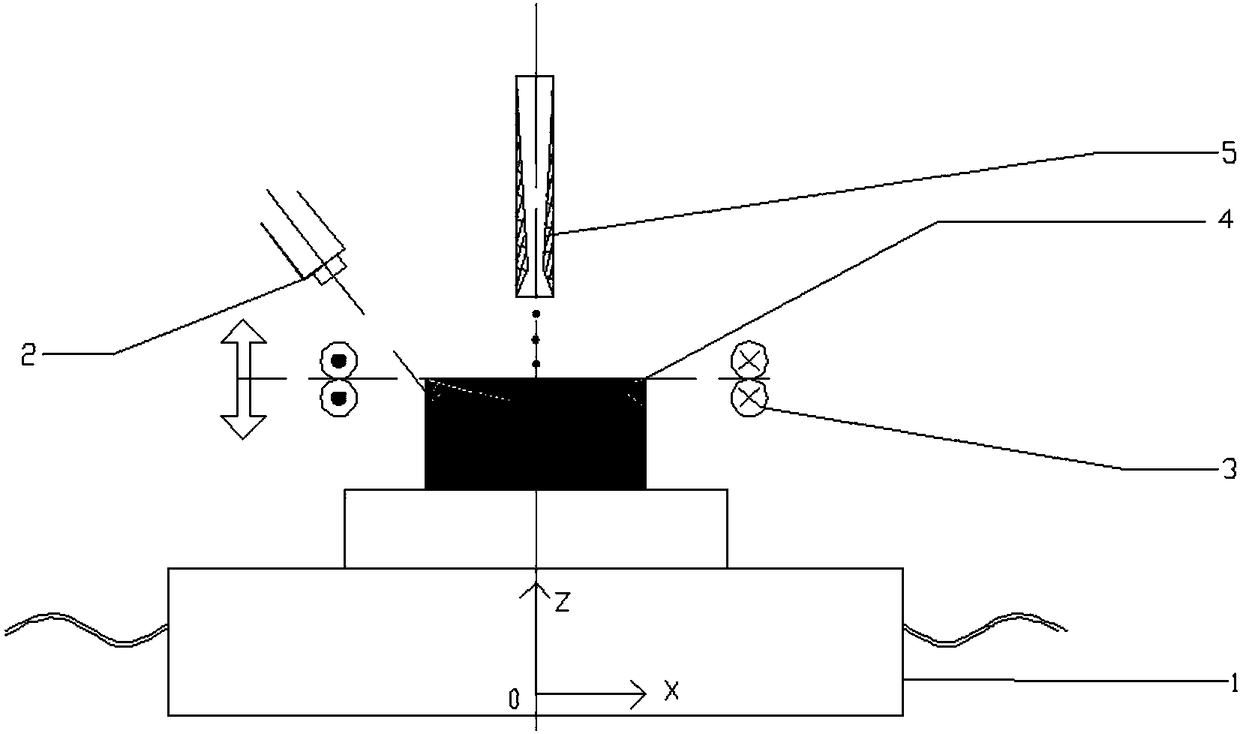

Method used

Image

Examples

Embodiment 1

[0030] In this example, TC4 (Ti-6Al-4V) is prepared. The shot peening device adopts the CS-2000 cold spray system independently developed by Xi'an Jiaotong University. The scanning speed is 0.5mm, the scanning speed is 8mm / s, the powder feeding volume is 2.5g / min, and the Z-axis lifting volume The overlap rate is 25%; the shot peening particles are stainless steel, the particle size is 300μm, the scanning speed is 10mm / s, the powder feeding rate is 20g / min, the gas pressure is 2.7MPa, and the shot peening time is 40s;

[0031] After depositing 100 layers, the formed cladding layer 4 is shot-peened. After the part is formed, the formed part is polished and corroded, and then placed under a digital optical microscope to observe the formed structure of the part.

[0032] Such as figure 2 As shown, the columnar grains inside the TC4 sample without induction heating-assisted shot peening are very coarse, and grow continuously through the cladding layer 4 along the deposition dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com