A kind of oil agent for continuous spun viscose filament and its preparation method and application

A technology of oil agent and filament, which is applied in the direction of textiles and papermaking, liquid-repellent fibers, plant fibers, etc., can solve the problem that the antistatic performance cannot fully meet the high-speed textile speed, and achieve excellent process passability, eliminate The effect of static electricity accumulation and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Raw materials

[0022] By weight percentage, it consists of 35% deionized with a conductivity of 5 μS / cm, 40% polyethylene glycol fatty acid ester, 15% fatty alcohol polyoxyethylene ether fatty acid ester and 10% polyether modified silicone phosphate sodium salt. in,

[0023] Polyethylene glycol fatty acid ester: polyethylene glycol laurate prepared from polyethylene glycol 600 with n=14 and lauric acid with 12 carbons.

[0024] Fatty alcohol polyoxyethylene ether fatty acid ester: lauryl alcohol polyoxyethylene ether n-butyrate prepared from lauryl alcohol with 12 carbons, n=20 polyoxyethylene ether and n-butyric acid with 4 carbons.

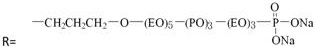

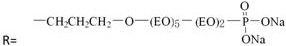

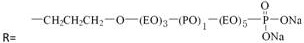

[0025] Sodium salt of polyether-modified siloxane phosphate: a sodium salt of polyether-modified siloxane phosphate with m=1, n=30, x=5, y=0, z=2.

[0026] (2) Preparation method

[0027] Deionized water was heated up to 50°C, polyethylene glycol laurate, lauryl polyoxyethylene ether n-butyrate, polyether modified siloxane phosph...

Embodiment 2

[0029] (1) Raw materials

[0030] By weight percentage, it consists of 37% deionized with a conductivity of 5 μS / cm, 38% polyethylene glycol fatty acid ester, 15% fatty alcohol polyoxyethylene ether fatty acid ester and 10% polyether modified silicone phosphate sodium salt. in,

[0031] Polyethylene glycol fatty acid ester: polyethylene glycol stearate prepared from polyethylene glycol 600 with n=14 and stearic acid with 16 carbons.

[0032] Fatty alcohol polyoxyethylene ether fatty acid ester: octadecyl alcohol polyoxyethylene ether n-butyrate prepared from stearyl alcohol with 18 carbons and n=23 polyoxyethylene ether and n-butyric acid with 4 carbons.

[0033] Sodium salt of polyether-modified siloxane phosphate: a sodium salt of polyether-modified siloxane phosphate with m=1, n=34, x=5, y=3, z=3.

[0034] (2) Preparation method

[0035] Deionized water was heated up to 50°C, polyethylene glycol stearate, stearyl polyoxyethylene ether n-butyrate, polyether modified sili...

Embodiment 3

[0037] (1) Raw materials

[0038] By weight percentage, it consists of 39% deionized with a conductivity of 5 μS / cm, 40% polyethylene glycol fatty acid ester, 15% fatty alcohol polyoxyethylene ether fatty acid ester and 6% polyether modified silicone phosphate sodium salt. in,

[0039] Polyethylene glycol fatty acid ester: polyethylene glycol laurate prepared from polyethylene glycol 4000 with n=91 and lauric acid with 12 carbons.

[0040] Fatty alcohol polyoxyethylene ether fatty acid ester: lauryl alcohol polyoxyethylene ether n-hexanoate prepared from lauryl alcohol with 12 carbons, n=23 polyoxyethylene ether and n-caproic acid with 6 carbons.

[0041] Polyether-modified siloxane phosphate sodium salt: it is a polyether-modified siloxane phosphate sodium salt with m=2, n=30, x=3, y=3, z=3.

[0042] (2) Preparation method

[0043] Heat deionized water to 50°C, add polyethylene glycol laurate, lauryl polyoxyethylene ether n-hexanoate, polyether modified silicone phosphate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com