Comprehensive utilization system of high-grade acetylene waste gas in process of cracking natural gas into acetylene

A technology for cracking natural gas and intermediate and advanced alkynes is applied in the field of comprehensive utilization system of advanced acetylene waste gas in the process of producing acetylene from natural gas cracking, which can solve the problems of low utilization rate of heat energy, low production stability, complicated system operation, etc. , Improve the safety level and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

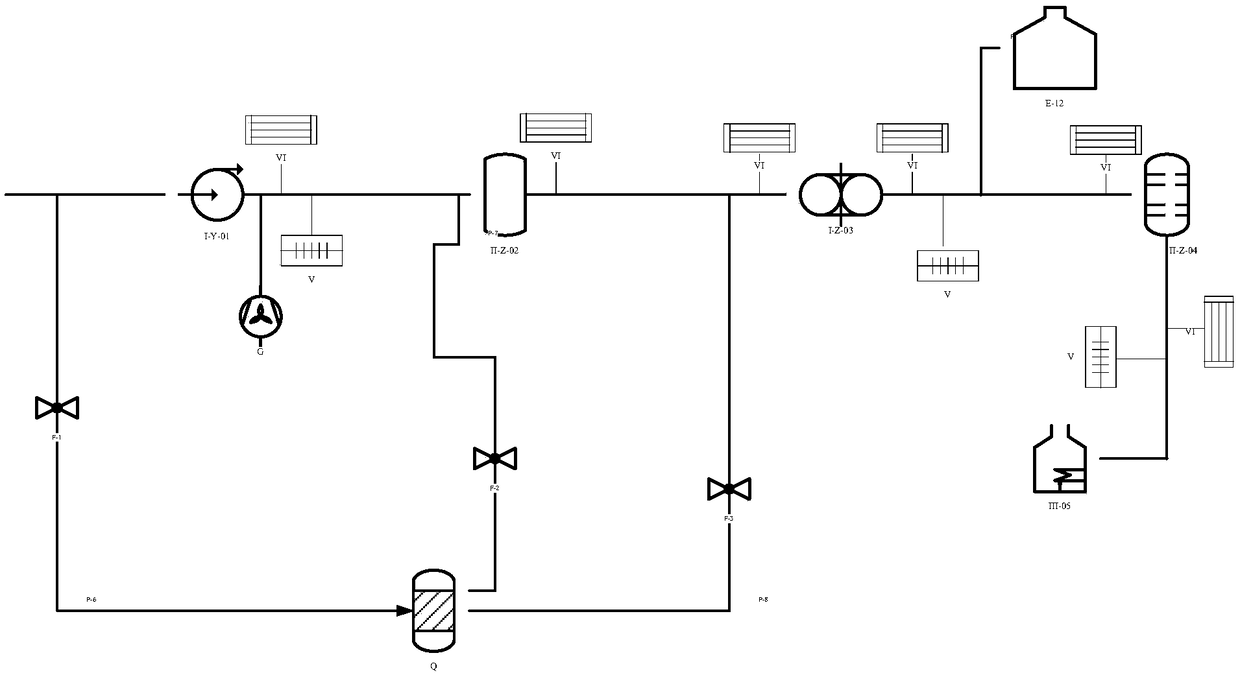

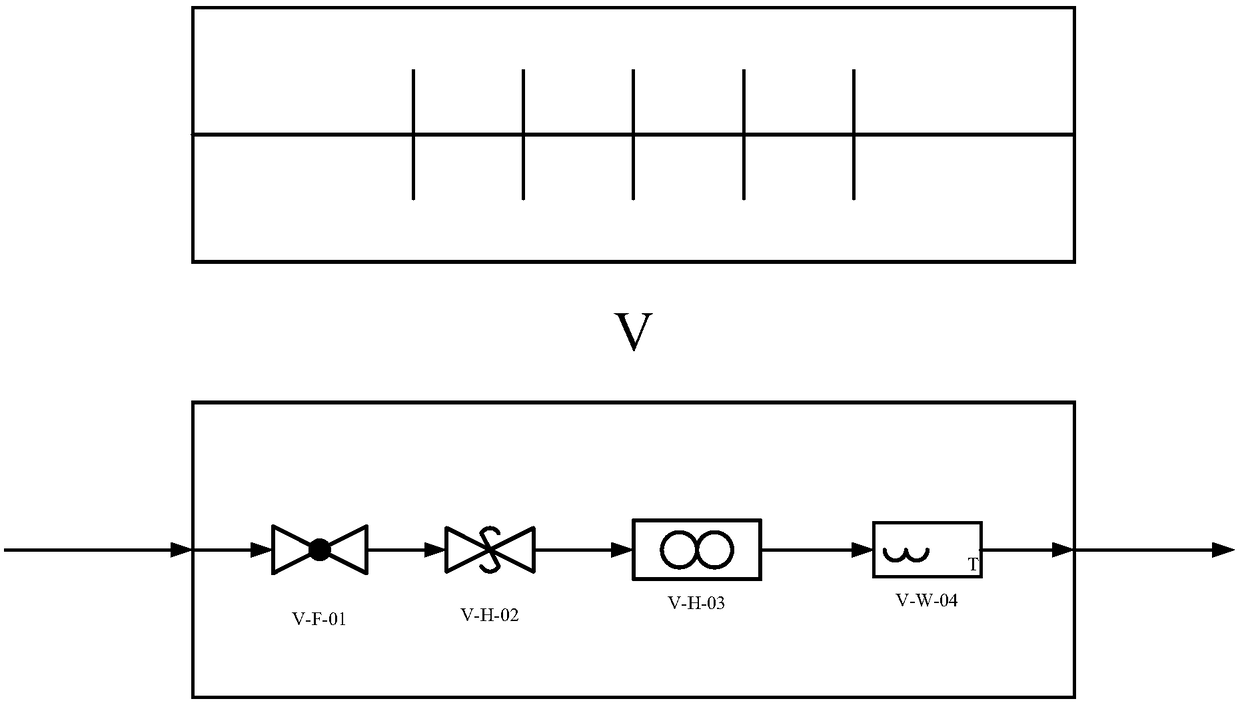

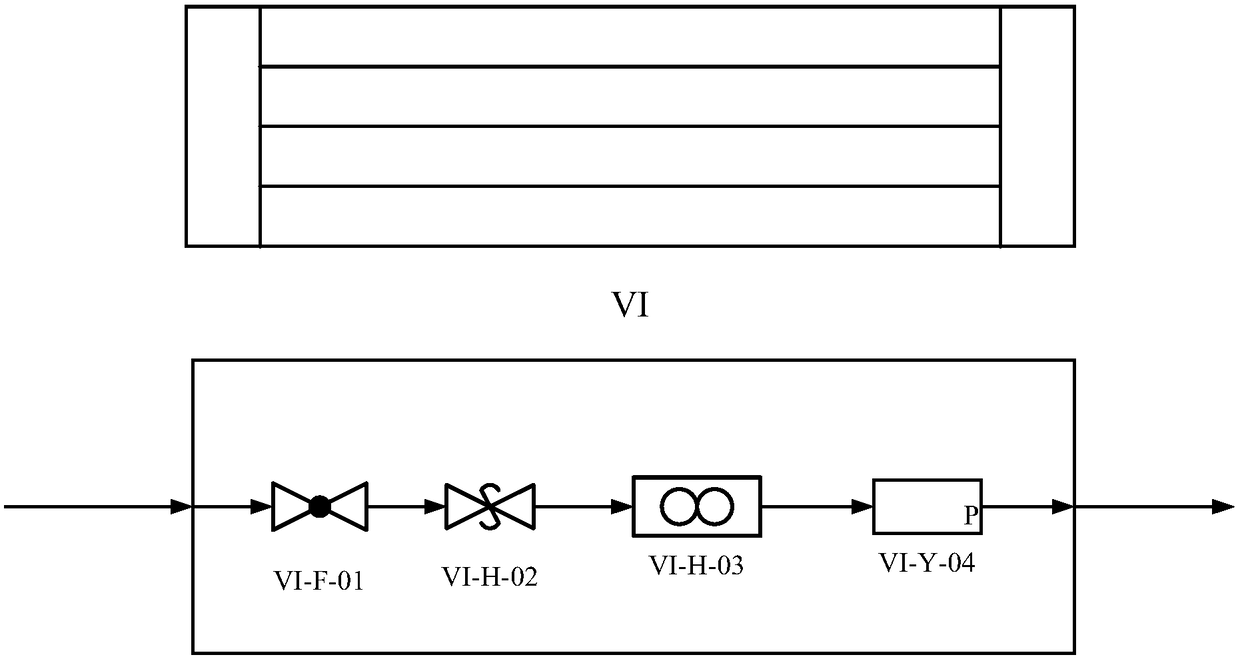

Image

Examples

Embodiment Construction

[0034] It should be noted that the preheating furnace of the natural gas acetylene plant in the previous process of natural gas cracking to acetylene is divided into an oxygen preheating furnace and a natural gas preheating furnace, each with 6 sets, and a total of 12 burners. The fuel gas design of the original burner is: Syngas is used for driving and natural gas is normally used. However, the high-grade acetylene waste gas comprehensive utilization system in the natural gas cracking to acetylene process of the present invention uses a mixture of high-grade acetylene mixed with natural gas for combustion, which improves the heat supply efficiency. Now compare the calorific value and post-combustion components of natural gas and advanced alkyne gas.

[0035] Table 1 Comparison of calorific value between high-grade alkyne gas and natural gas

[0036]

[0037]

[0038] Natural gas is calculated according to the highest calorific value. It can be seen that the calorific v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com