Monatomic noble metal catalyst, as well as preparation method and application thereof in low-temperature catalytic-oxidizing formaldehyde

A precious metal catalyst, precious metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. To achieve the effect of improving properties, reducing usage, and enhancing purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

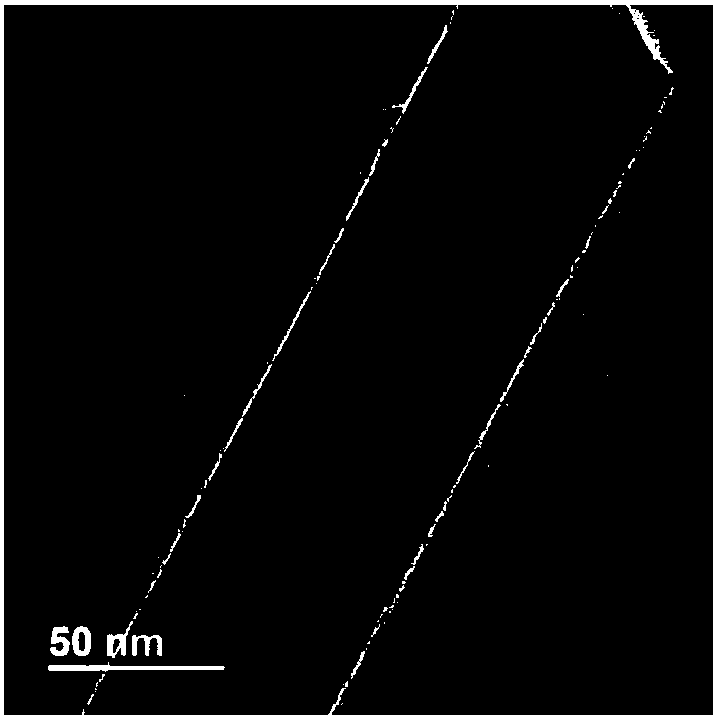

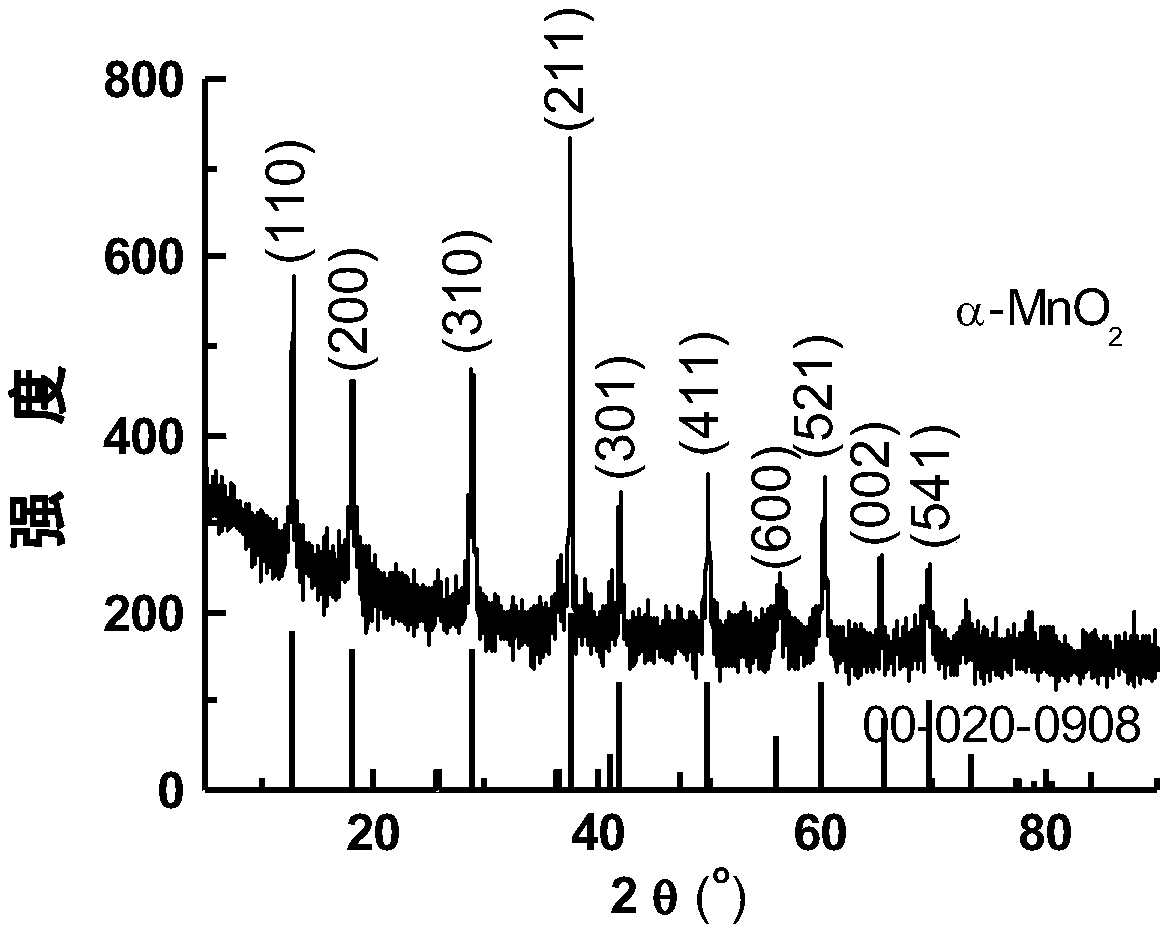

[0082] Take 2 g of the manganese dioxide rod-shaped carrier prepared in Comparative Example 1 and ultrasonically disperse it in 200 mL of deionized water, add 1 mL of HAuCl with a concentration of 0.01 g / mL 4 aqueous solution, stirred for 1 h, and 0.5 g of 30 wt.% H 2 o 2 Dissolve in 50 mL deionized water, add it dropwise to manganese dioxide and HAuCl 4 In the suspension, continue to stir for 2 hours after dropping, directly filter and wash, dry at 100°C, and roast in a muffle furnace at 200°C for 2 hours to obtain a precious metal catalyst with a gold content of 0.25%, named 0.25 %Au / MnO 2 .

[0083] HRTEM-HAADF-Cs-STEM tested (see Figure 7 ), indicating that the precious metal gold in the synthesized catalyst did not agglomerate and achieved single-atom dispersion.

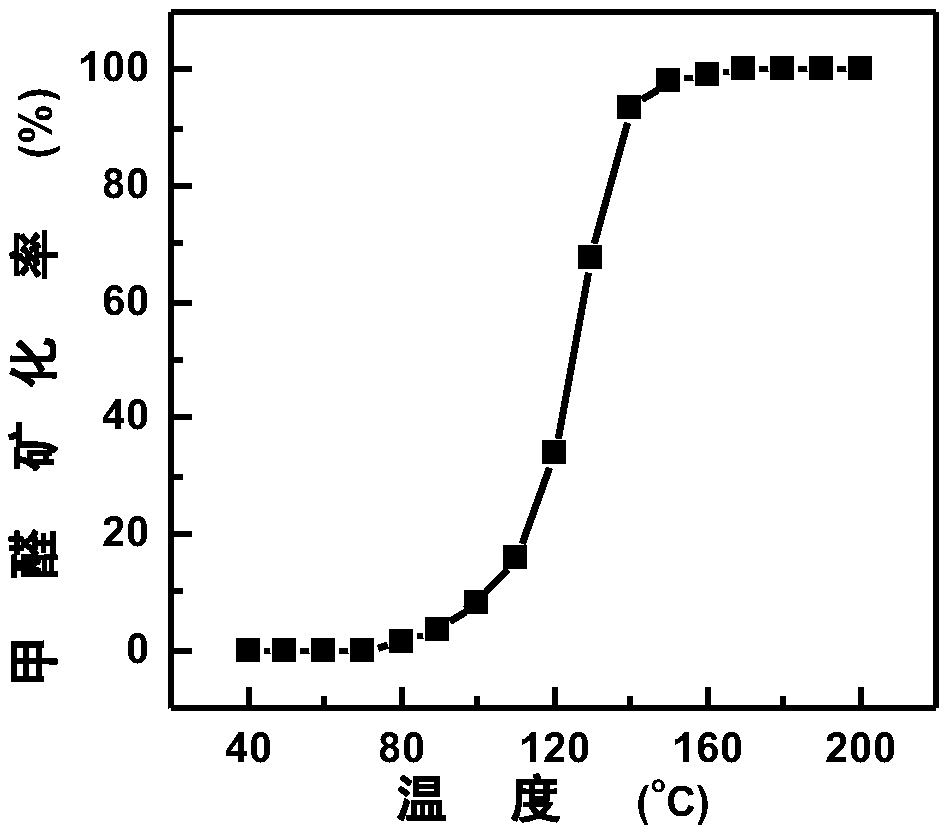

[0084] Take 66mg noble metal catalyst 0.25% Au / MnO 2 Place in a quartz reaction tube, feed a reaction gas containing 500ppm formaldehyde, control the reaction space velocity at 60000mL / (g h), and gradual...

Embodiment 2

[0087] Other steps are with embodiment 1, difference only is that HAuCl 4 Aqueous solution is replaced by H 2 PtCl 6 Prepare a noble metal catalyst with a platinum content of 0.25% in aqueous solution, named 0.25% Pt / MnO 2 .

[0088] HRTEM tested (see Figure 10 ), indicating that the platinum in the synthesized catalyst did not agglomerate and achieved single-atom dispersion.

Embodiment 3

[0090] Other steps are with embodiment 1, difference only is that HAuCl 4 Aqueous solution replaced by PdCl 2 Aqueous solution to prepare a noble metal catalyst with a palladium content of 0.25%, named 0.25% Pd / MnO 2 .

[0091] HRTEM tested (see Figure 11 ), indicating that the palladium in the synthesized catalyst did not agglomerate and achieved single-atom dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com