Method for preparing cyclopropyl carbinol

A technology of cyclopropylmethanol and cyclopropylcarboxylate, which is applied in the field of preparation of cyclopropylmethanol, can solve the problems of safety accidents and high price, and achieve the effects of less three wastes, simple post-treatment and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 1L three-neck flask, add 100g (1mol) methyl cyclopropanate, 57g (1.5mol) sodium borohydride, 500mL methanol, then cool down to 2°C, add 66.67g (0.5mol) aluminum trichloride in batches, and react overnight , adding saturated ammonium chloride aqueous solution to quench the reaction, filtered, the filtrate was concentrated, and rectified to collect 53.49 g of the product, with a yield of 74.3%.

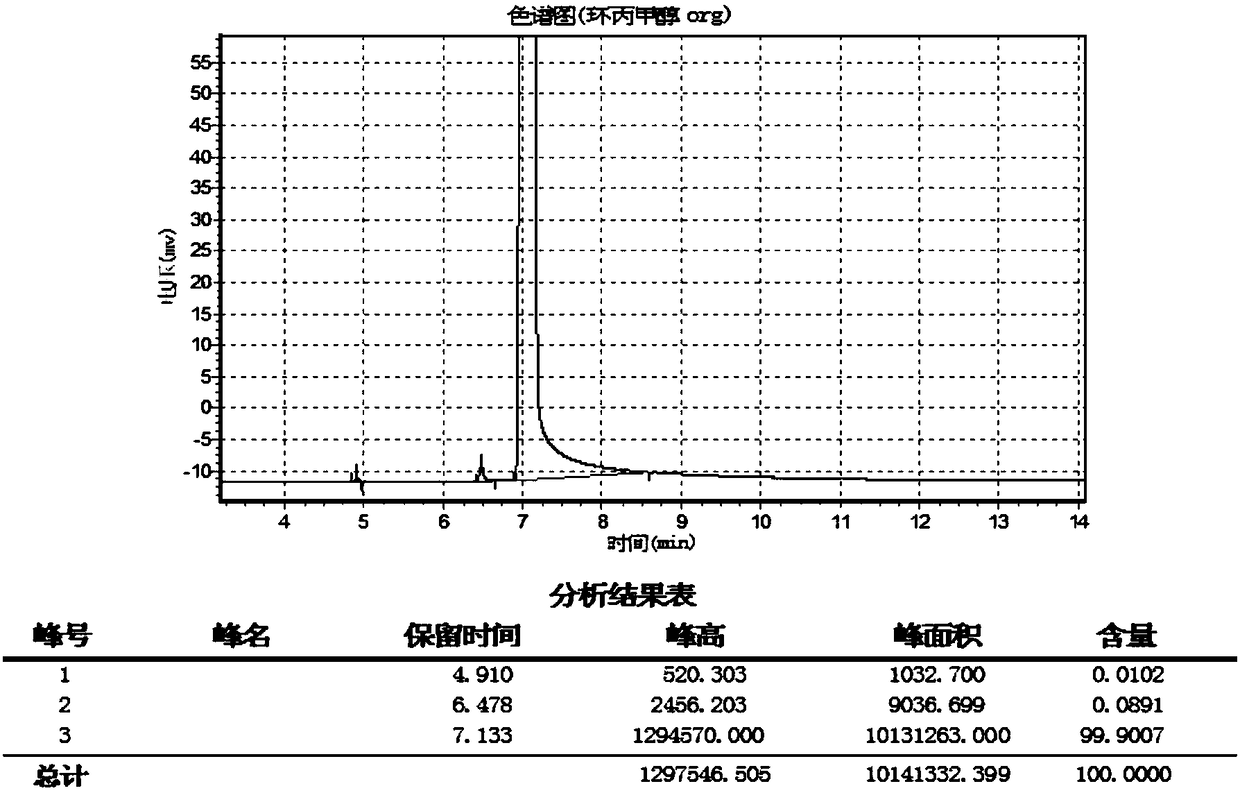

[0025] Such as figure 1 Shown is the gas chromatogram of cyclopropylmethanol obtained in the present invention, it can be seen that the product obtained in the present invention has a higher purity.

Embodiment 2

[0027] In a 1L three-neck flask, add 100g (1mol) methyl cyclopropanate, 57g (1.5mol) sodium borohydride, 500mL methanol, then lower the temperature to 0°C, add 42.35g (1mol) lithium chloride in batches, react overnight, add saturated chlorine Aqueous ammonium chloride solution was used to quench the reaction, filtered, the filtrate was concentrated, and rectified to collect 39.6 g of the product, with a yield of 55%.

Embodiment 3

[0029] 1L three-neck flask, add 100g (1mol) methyl cyclopropaneformate, 57g (1.5mol) sodium borohydride, 500mL methanol, then lower the temperature to 0°C, add 250g (1mol) tin tetrachloride in batches, react overnight, add saturated chlorine Aqueous ammonium chloride solution was used to quench the reaction, filtered, the filtrate was concentrated, and rectified to collect 47.23 g of the product, with a yield of 65.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com