High-temperature plugging agent system used for heavy-oil thermal recovery oil reservoir

A technology of thermal oil recovery and high temperature, which is applied in the field of plugging agents, can solve the problems that polyacrylamide gel is not suitable for plugging steam channeling, etc., and achieve the goal of improving the plugging performance of plugging agents, excellent temperature resistance, and less formation damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The solvent used in this high-temperature plugging agent system for heavy oil thermal recovery oil reservoirs is distilled water. A certain mass of polymer powder is stirred and dissolved in a certain amount of water to fully dissolve, and then the cross-linking agent, stabilizer, buffer, chelating agent, and Slowly add the mixture and free radical scavenger into the polymer-containing aqueous solution, and pay attention to rapid stirring when adding solid phase particles. Then the solution was stirred for 2 hours to ensure uniform mixing, and fully stirred and dissolved to obtain a high-temperature plugging agent system for heavy oil thermal recovery reservoirs. The composition of this embodiment is shown in Table 1.

[0035] Table 1

[0036] name

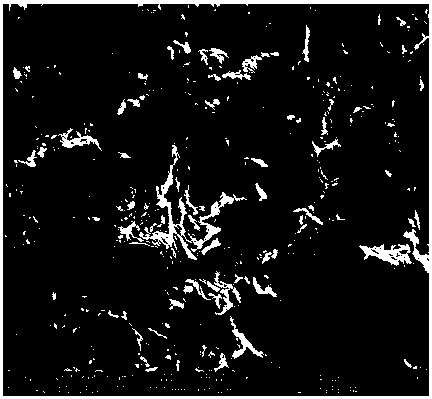

[0037] Scanning electron microscope was used to observe its microscopic morphology. figure 1 The local structure diagram of the high-temperature blocking agent system in Example 1 can be seen, and the prepared ...

Embodiment 2

[0039] The solvent used in this high-temperature plugging agent system for heavy oil thermal recovery oil reservoirs is distilled water. A certain mass of polymer powder is stirred and dissolved in a certain amount of water to fully dissolve, and then the cross-linking agent, stabilizer, buffer, chelating agent, and Slowly add the mixture and free radical scavenger into the polymer-containing aqueous solution, and pay attention to rapid stirring when adding solid phase particles. Then the solution was stirred for 2 hours to ensure uniform mixing, and fully stirred and dissolved to obtain a high-temperature plugging agent system for heavy oil thermal recovery reservoirs. The composition of this embodiment is shown in Table 2.

[0040] Table 2

[0041] name

Embodiment 3

[0043] The solvent used in this high-temperature plugging agent system for heavy oil thermal recovery oil reservoirs is distilled water. A certain mass of polymer powder is stirred and dissolved in a certain amount of water to fully dissolve, and then the cross-linking agent, stabilizer, buffer, chelating agent, and Slowly add the mixture and free radical scavenger into the polymer-containing aqueous solution, and pay attention to rapid stirring when adding solid phase particles. Then the solution was stirred for 2 hours to ensure uniform mixing, and fully stirred and dissolved to obtain a high-temperature plugging agent system for heavy oil thermal recovery reservoirs. The composition of this embodiment is shown in Table 3.

[0044] table 3

[0045] name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com