Carbon quantum dot with zwitter-ion structure on surface as well as preparation method and application of carbon quantum dot

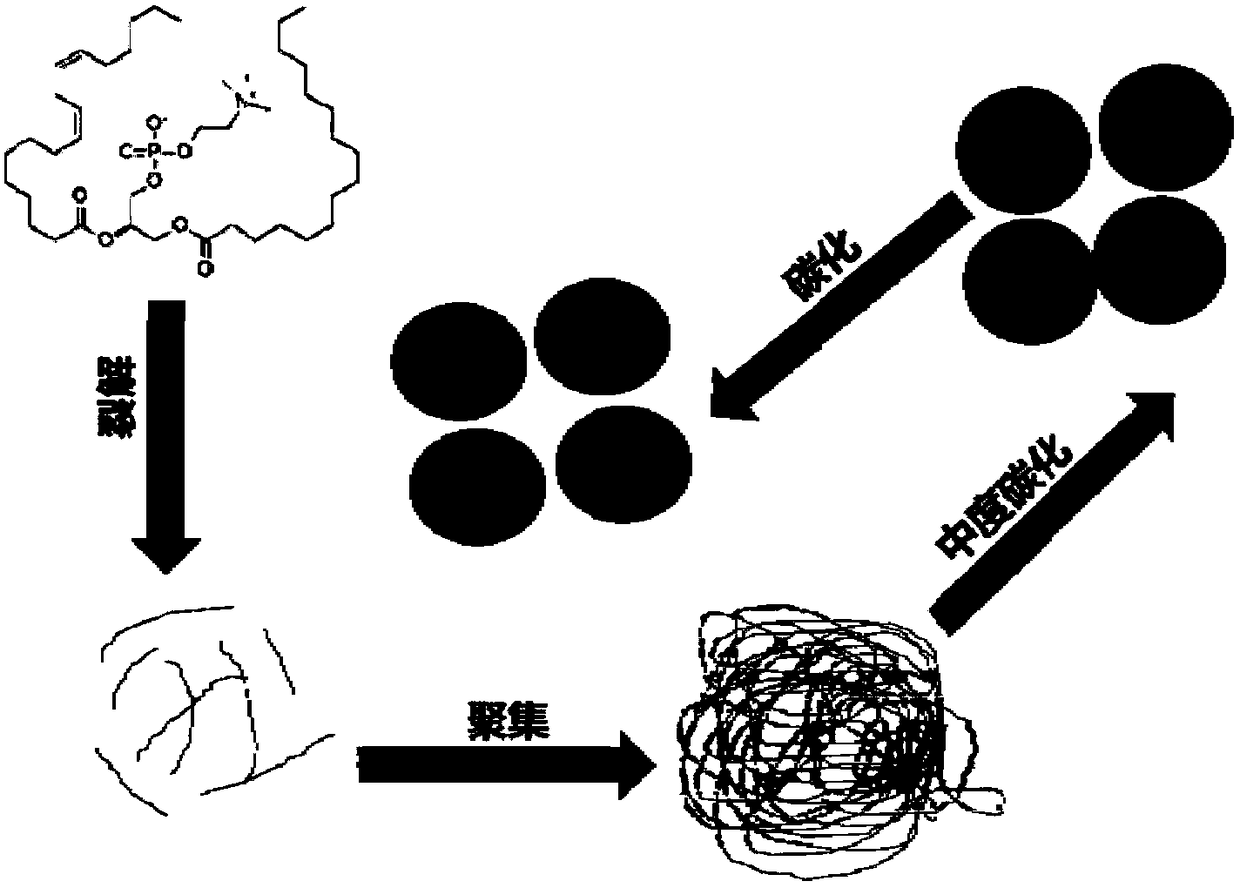

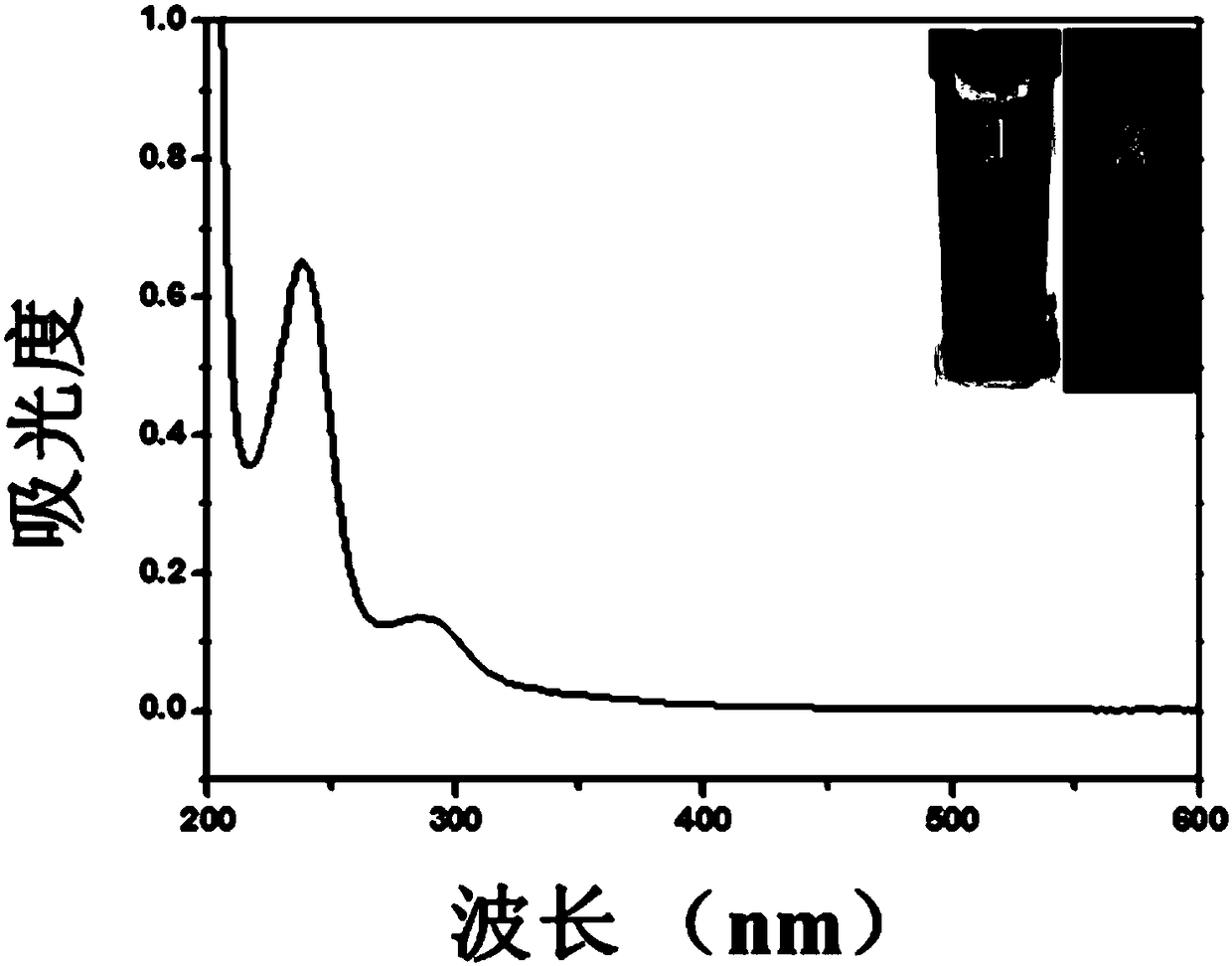

A technology of carbon quantum dots and zwitterions, which is applied to carbon quantum dots with a zwitterionic structure on the surface and the field of preparation thereof, can solve problems such as low stability, achieve good stability, realize multi-color fluorescence imaging, and monodispersity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Carbon quantum dots with a zwitterionic structure on the surface are prepared by the following method:

[0040] Step 1: Disperse 1g of lecithin in 30mL of water.

[0041] The second step: transfer the solution to the reactor, and react at 180°C for 8 hours.

[0042] Step 3: When the reactor is cooled to 15°C, centrifuge at 12000rpm for 30min, and then filter with a 220nm filter membrane to remove the residue.

[0043] The fourth step: Freeze-drying at -60°C, with a vacuum of 8 Pa, and a drying time of 24 hours.

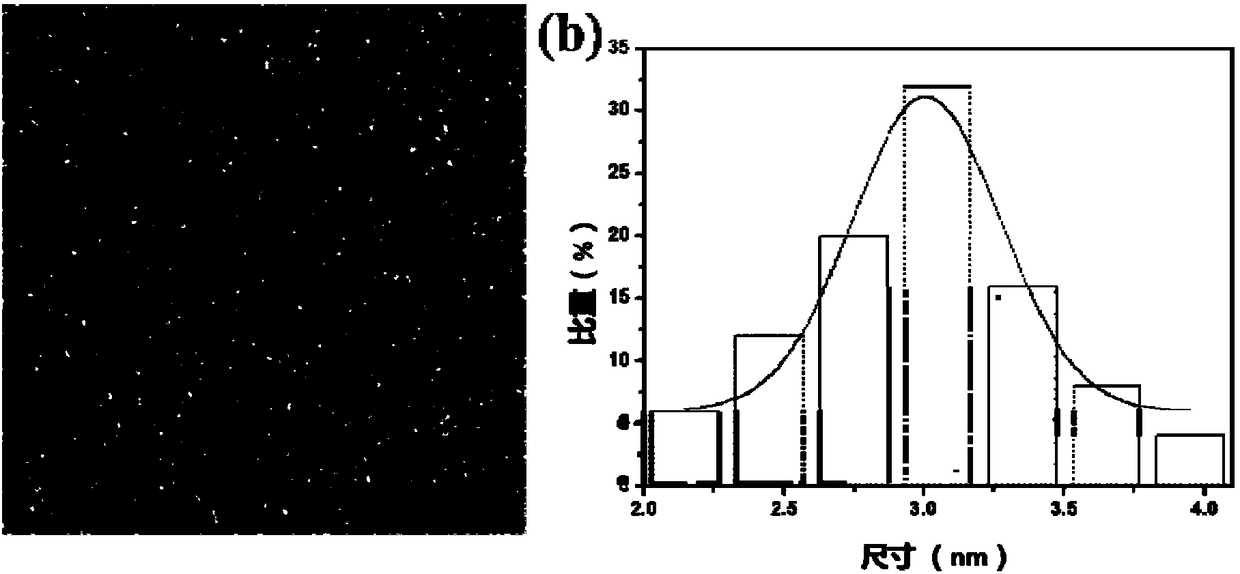

[0044] The prepared carbon quantum dots were characterized by a transmission electron microscope, and the test results showed that the average particle size was 2.9nm. The yield was 53.12% by the ratio of the mass of the obtained product to the mass of the reactant.

Embodiment 2

[0046] Carbon quantum dots with a zwitterionic structure on the surface are prepared by the following method:

[0047] Step 1: Disperse 1g of lecithin in 100mL of water.

[0048] The second step: transfer the solution to a reaction kettle, and react at 200°C for 24 hours.

[0049] Step 3: When the reactor is cooled to 10°C, centrifuge at 11,000rpm for 20min, and then filter with a 220nm filter membrane to remove the residue.

[0050] The fourth step: Freeze-drying at -60°C, with a vacuum of 8 Pa, and a drying time of 24 hours.

[0051] The prepared carbon quantum dots were characterized by a transmission electron microscope, and the test results showed that the average particle size was 4.3nm. The yield was 51.64% by the ratio of the mass of the obtained product to the mass of the reactant.

Embodiment 3

[0053] Carbon quantum dots with a zwitterionic structure on the surface are prepared by the following method:

[0054] Step 1: Disperse 1g of lecithin in 20mL of water.

[0055] The second step: transfer the solution to the reactor, and react at 170°C for 6 hours.

[0056] Step 3: When the reactor is cooled to 35°C, centrifuge at 14000rpm for 10min, and then filter with a 220nm filter membrane to remove the residue.

[0057] The fourth step: freeze-drying at -45°C, vacuum degree of 9Pa, and drying time of 48h.

[0058] The prepared carbon quantum dots were characterized by a transmission electron microscope, and the test results showed that the average particle size was 3.3nm. The yield of carbon quantum dots was 53.99% by the ratio of the mass of the obtained product to the mass of the reactant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com