Bonded neodymium iron boron magnet and fast setting preparation method

A rapid curing, NdFeB technology, applied in the direction of magnetic objects, inductors/transformers/magnets manufacturing, magnetic materials, etc., can solve the problems of poor product consistency and long curing time, achieve dimensional consistency and strength improvement, and reduce production cost, and the effect of shortening the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

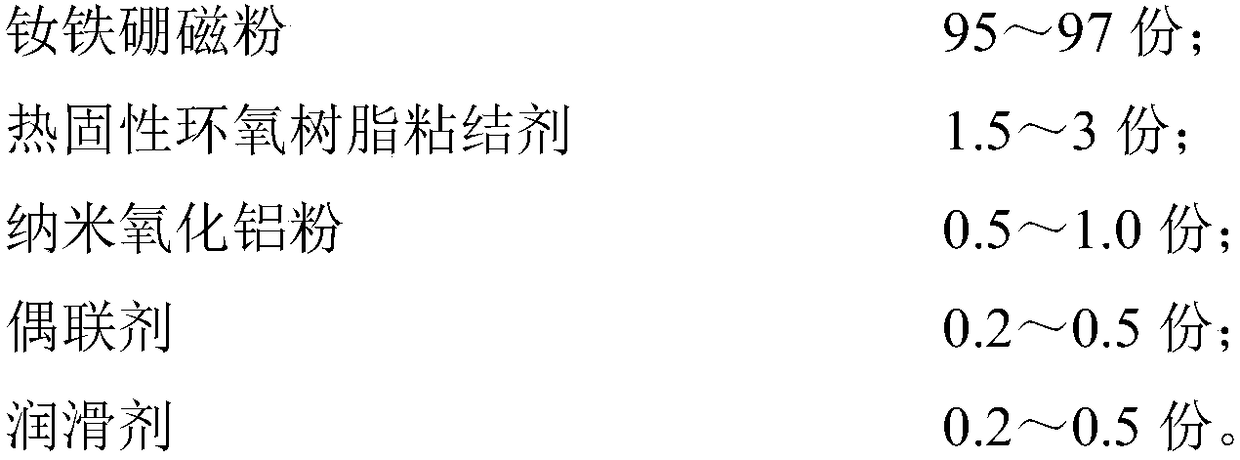

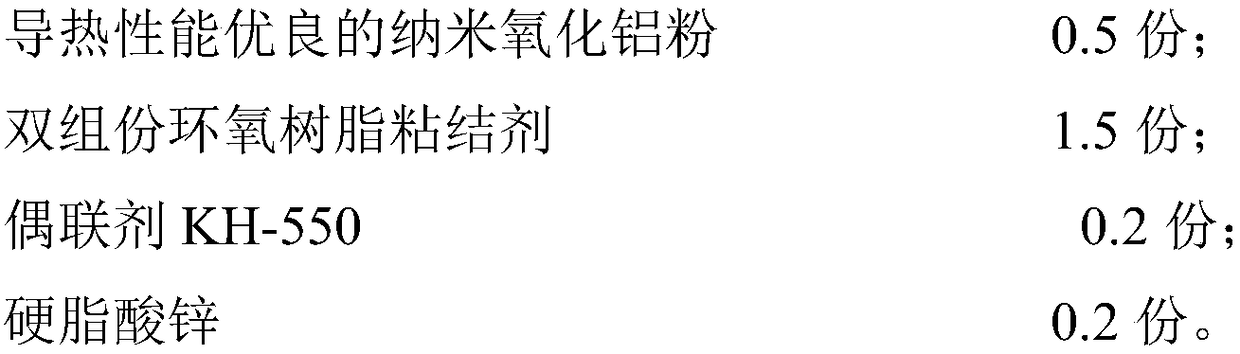

[0066] The bonded NdFeB magnet provided in this example is composed of the following components by weight:

[0067]

[0068]

[0069] In this example, the preparation of bonded NdFeB magnets is completed through the following rapid preparation process:

[0070] (1) Crushing the flaky NdFeB magnetic powder through a 200-mesh sieve.

[0071] (2) Add 95 parts of sieved NdFeB magnetic powder and 0.5 part of nano-alumina powder to 6 parts of acetone solution with 1.5 parts of thermosetting binder and 0.2 parts of coupling agent KH-550, and stir until the acetone is completely Volatilize to get rubber powder.

[0072] (3) mixing the rubber powder obtained in step (2) with 0.2 part of zinc stearate to obtain a magnetic powder mixture;

[0073] (4) putting the magnetic powder mixture obtained in step (3) into molds and pressing under a certain pressing pressure to obtain a green body of magnet;

[0074] (5) The green body of the magnet obtained in step (4) was quickly cured i...

example 2

[0077] The bonded NdFeB magnet provided in this example is composed of the following components by weight:

[0078]

[0079] In this example, the preparation of bonded NdFeB magnets is completed through the following rapid preparation process:

[0080] (1) Crushing the flaky NdFeB magnetic powder through a 250-mesh sieve.

[0081] (2) Add 96 parts of sieved NdFeB magnetic powder and 0.8 part of nano-alumina powder to 7 parts of acetone solution with 2 parts of thermosetting binder and 0.3 part of coupling agent KH-550, and stir until the acetone is completely Volatilize to get rubber powder.

[0082] (3) mixing the rubber powder obtained in step (2) with 0.4 part of calcium hard acid to obtain a magnetic powder mixture;

[0083] (4) putting the magnetic powder mixture obtained in step (3) into molds and pressing under a certain pressing pressure to obtain a green body of magnet;

[0084] (5) Rapidly solidify the green body of the magnet obtained in step (4) in a tunnel f...

example 3

[0087] The bonded NdFeB magnet provided in this example is composed of the following components by weight:

[0088]

[0089] In this example, the preparation of bonded NdFeB magnets is completed through the following rapid preparation process:

[0090] (1) Crushing the flaky NdFeB magnetic powder through a 220-mesh sieve.

[0091] (2) Add 97 parts of sieved NdFeB magnetic powder and 1 part of nano-alumina powder to 6.5 parts of acetone solution with 2.5 parts of thermosetting binder and 0.4 parts of coupling agent KH-550, and stir until the acetone is completely Volatilize to get rubber powder.

[0092] (3) uniformly combining the rubber powder obtained in step (2) and 0.4 part of zinc stearate to obtain a magnetic powder mixture;

[0093] (4) putting the magnetic powder mixture obtained in step (3) into molds and pressing under a certain pressing pressure to obtain a green body of magnet;

[0094] (5) Rapidly solidify the green body of the magnet obtained in step (4) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com